Placing of Forms

concrete, beams, flanges, wood, fig and stilting

PLACING OF FORMS In an article on the placing of rods and forms for concrete floors and beams to secure the best results, Thomas Potter says: "It is a desirable practice to wash the rods or bars with liquid cement before they are embedded in the con crete; the rods should be clean and cold, and the process not done in the sun. If the rods are damp or moist, so much the better, and the cement should be of the con sistency of cream.

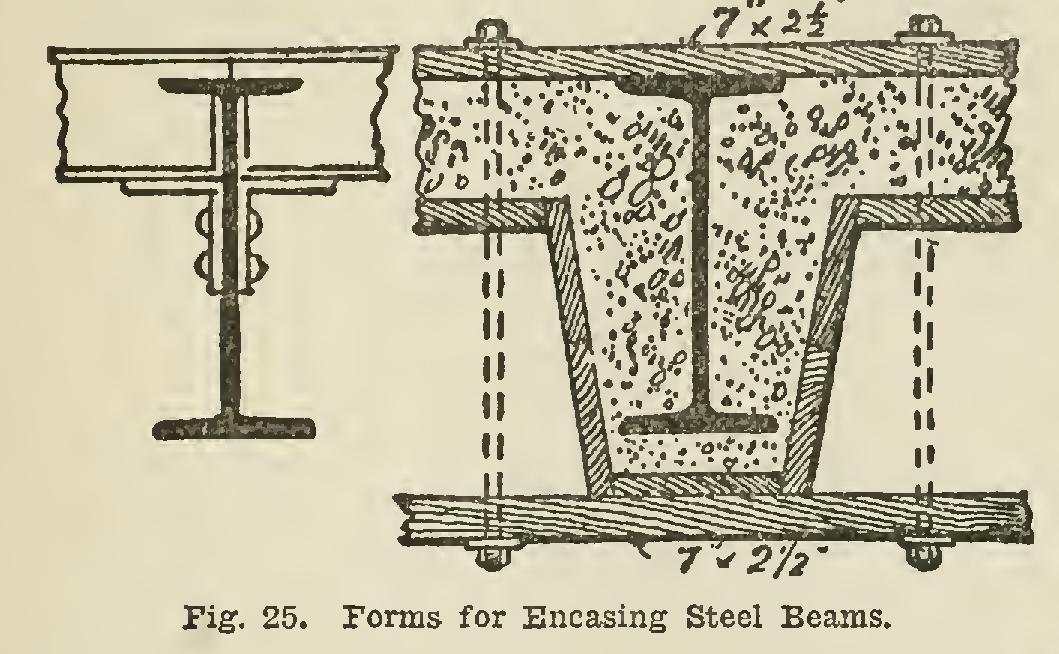

" 'Forms,' or the temporary wood casings used for upholding the concrete in a soft state, and called in America `falsework,' take away much of the carpenter's trade by dispensing with wood beams, joists, and floor boards; but in many instances this is more than made up for by the large amount of labor and materials necessary for their construction, more especially where beams are numerous. Where no reinforced beams are required, or steel beams are employed, the falsework for the actual floor is much simplified; the under side is straight throughout, and it is an easy matter to arrange the false work necessary to support the concrete, either by props beneath or suspended by bolts attached to timbers over; but it is often the case that the concrete is not of the same thickness as the joists are in depth, so they have to be stilted with concrete, as shown in Fig. 24. As thinner concrete for floors than formerly is becoming general, stilting is usually adopted where main steel beams are employed a considerable distance apart, and small trans verse joists are attached thereto to support the concrete, iron angle bearers riveted to the beams being general at one time, as in Fig. 25, but stilting is preferable. It costs less; it is a protection in case of fire; it assists to stiffen the beams and to strengthen them, and reduces their flexure. With a view to protecting the bottom flanges of the steel beams, it is sometimes specified that they shall be encased with one inch or two inches in thickness of concrete, as in Fig. 25. With the forms for the stilting in position, this is somewhat difficult ; the concrete is simply pushed under with a piece of iron or wood crooked at one end. When the forms are released, por

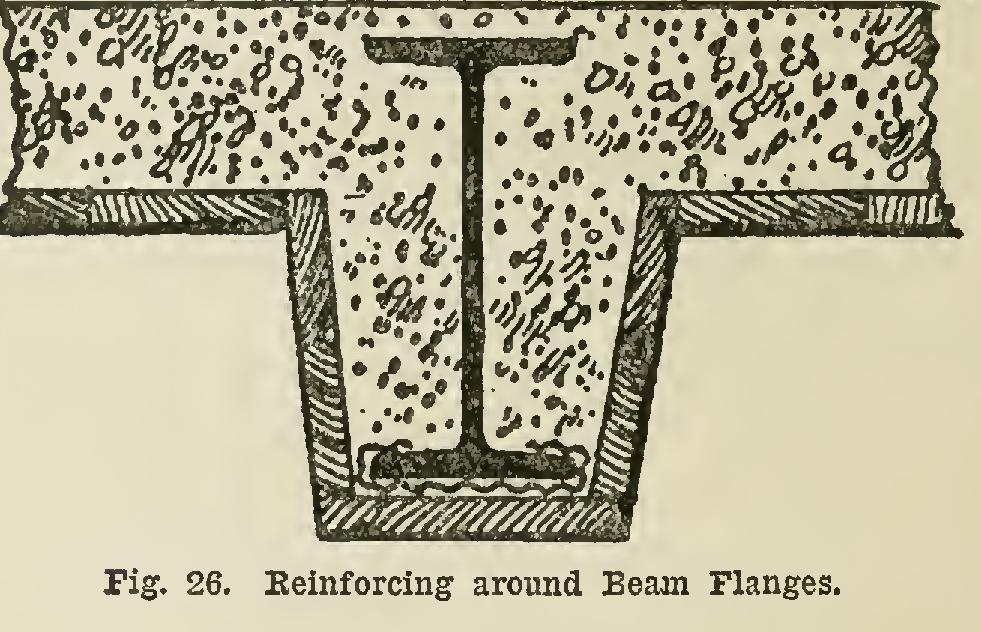

tions of the concrete often come away with them, and the flanges of the beams are visible, the result being that the bare places are at the first opportunity filled up with a dab of mortar ; sometimes coarse grout is run under the flanges. It is doubtful whether the flanges are efficiently protected in this way, and whether a wrapping of ex panded metal lathing around the bottom flanges, tucked into the concrete on each side, as in Fig. 26, and plastered with lime and hair mortar, is not very much better. Some times steel wires are bent in the form of a stirrup and embedded in the concrete under the flanges, and their ends anchored in the concrete stiltings.

"This is a difficult thing to accomplish, and is very seldom satisfactory.

"Sir M. Shaw, when chief of the London Fire Brigade, said if only an inch of plastering mortar could be made to stay on all exposed portions of steel beams, the danger from fire through their collapse would be largely minimized.

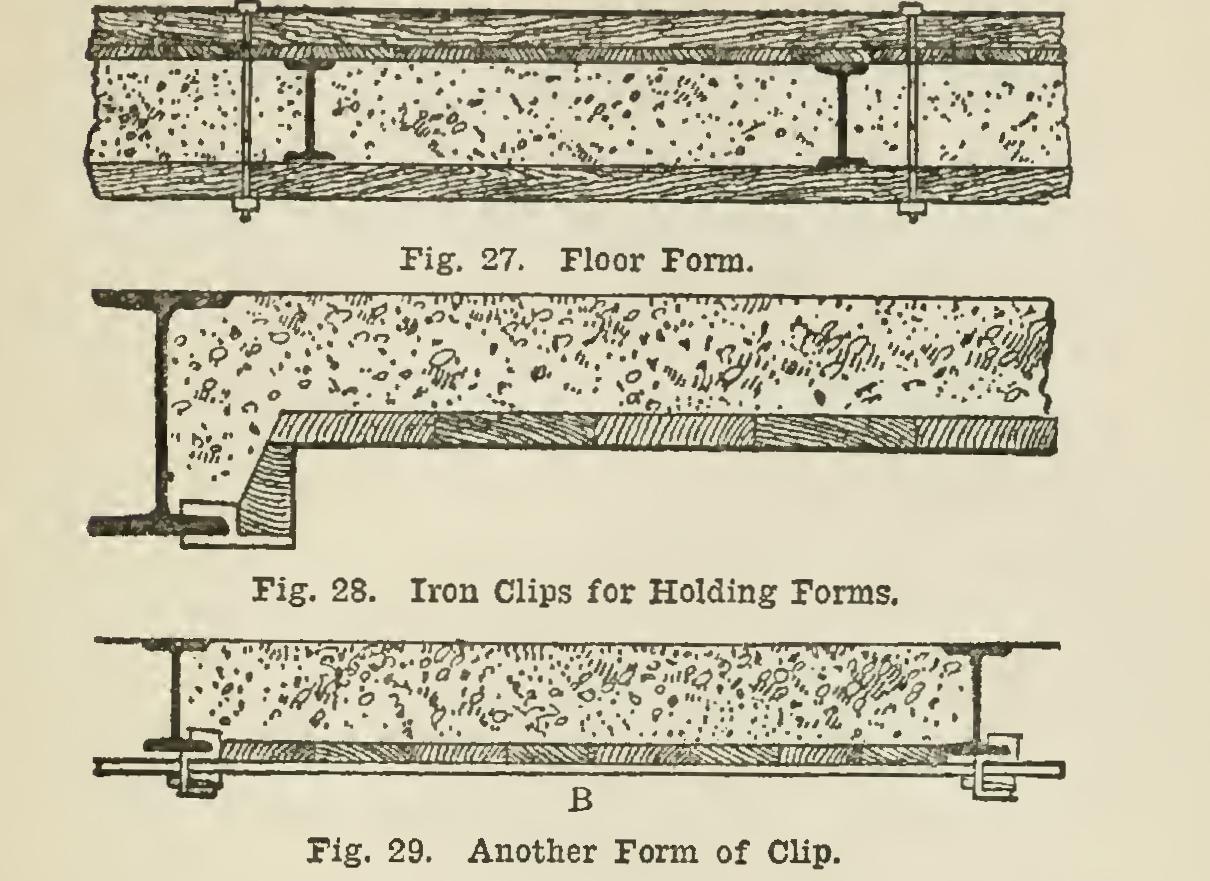

"Forms for floors are usually kept in place by bolts attached to wood battens resting on the top of the beams and to others below, as in Fig. 27. Evidence of the trouble caused by so apparently trivial a matter as temporary arrangements to keep the concrete in place until it is set, is to be found in the fact that more than two dozen patents have been taken out with this object alone.

"After experimenting in various directions for the same purpose, I have adopted and patented some very simple methods.

"Fig. 28 consists of tee-iron clips about three inches in length, the webs bent so as to wedge them on the bottom flanges of the beams. Stilting pieces of wood of the depth required bear on the flange of the clip, a few small wedges being used between the wood and the clip, which, when removed, enable the stilting form to be released.