Hot-Air Heating

air, pipes, heat, furnace, capacity, cold-air, duct, shaft, ventilating and cold

Heat Pipes. The heat pipes conveying air from the furnace should have a good upward slope in the cellar. If necessary, the bottom of the fur nace should be placed below the level of the cellar floor, in order to secure a slope in the heat pipes. When it is necessary to use pipes of different lengths to reach dif ferent rooms of the same size, the longer pipes should be larger in diameter than the shorter pipes. When a large number of heat pipes are taken off from the furnace, they should average smaller in diameter than the average di ameter when there are but a few heat pipes.

The total capacity of all the heat pipes leading from a furnace should never exceed 40 per cent of the area of the circle of the casing; and in good furnace practice, this total capacity of heat pipes should usually be considerably less than 40 per cent of the area of the circle of the casing.

In practice the diameters of the several pipes must be determined by the conditions and requirements of each particular case. The capacity of heat pipes leading to vertical parti tion flues for heating rooms in upper stories, may be somewhat less than that of pipes run ning to first-floor rooms. When the vertical flues are of sufficient capacity, it is seldom diffi cult to convey heat to second or third floor rooms, unless the mistake is made of attempting to carry the heat up in exposed outer walls.

When the cone-top upper casing is used, the several pipes should be brought out from the sloping sides as high up as possible, and the top sides of the pipes should all be on an exact level. Where the straight-sided flat-top upper casing is used, the pipes are brought out from the top, in which case the elbows should all be of the same height from the top of the furnace. Both heat pipes and smoke pipe should be per fectly tight, so that no air can enter them except through the furnace.

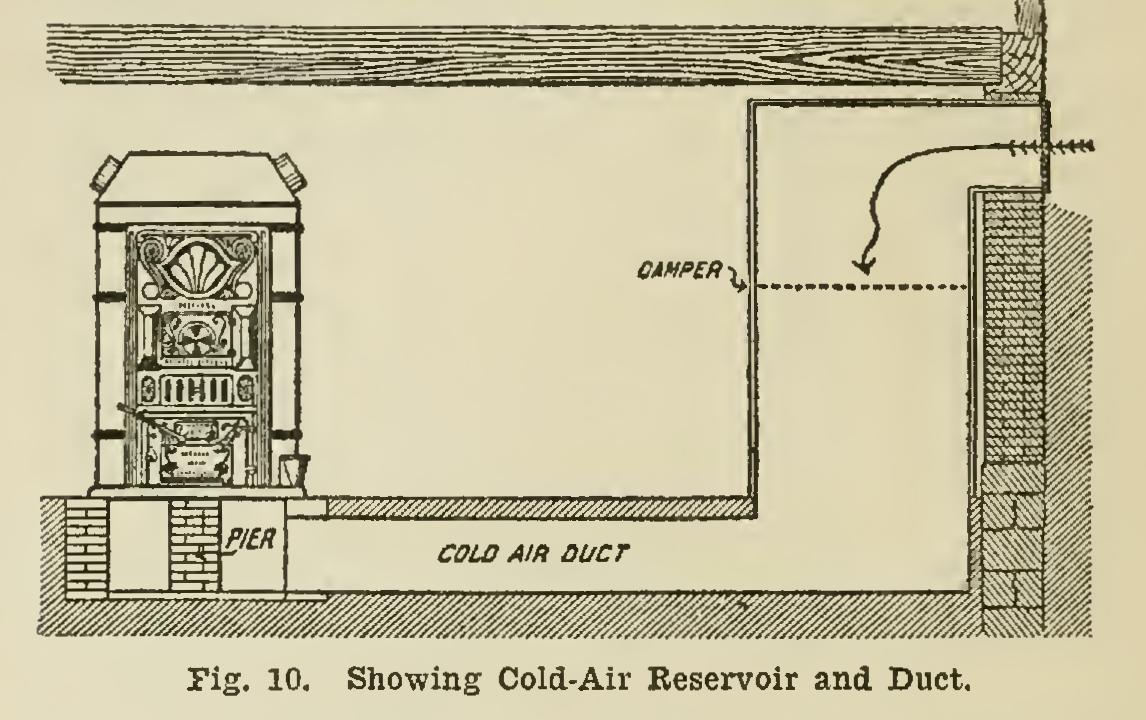

Cold-Air Supply. No hot-air furnace will do its work properly unless provided with an ade quate cold-air supply. In the cheap form of in stallation, it is invariably noted that the furnace is supplied with basement air through a fret work base of the furnace. Aside from showing poor practice, this method creates an unhealth ful condition. Air from outside the building itself should be used; and the necessary supply should, if possible, be admitted from the north or northwest sides. A cellar window may be utilized for the purpose. Just inside the cellar window or other similar suitable opening, the cold-air duct should be enlarged to about three times the required capacity. From the bottom of this duct the connection with the furnace may be made, the pipe running either below the floor of the cellar or above it, according to cir cumstances surrounding the installation. This large duct forms a reservoir for the accumula tion of cold air, and this reserve supply prevents prevailing high or variable winds from inter fering with the steady flow of air to the furnace.

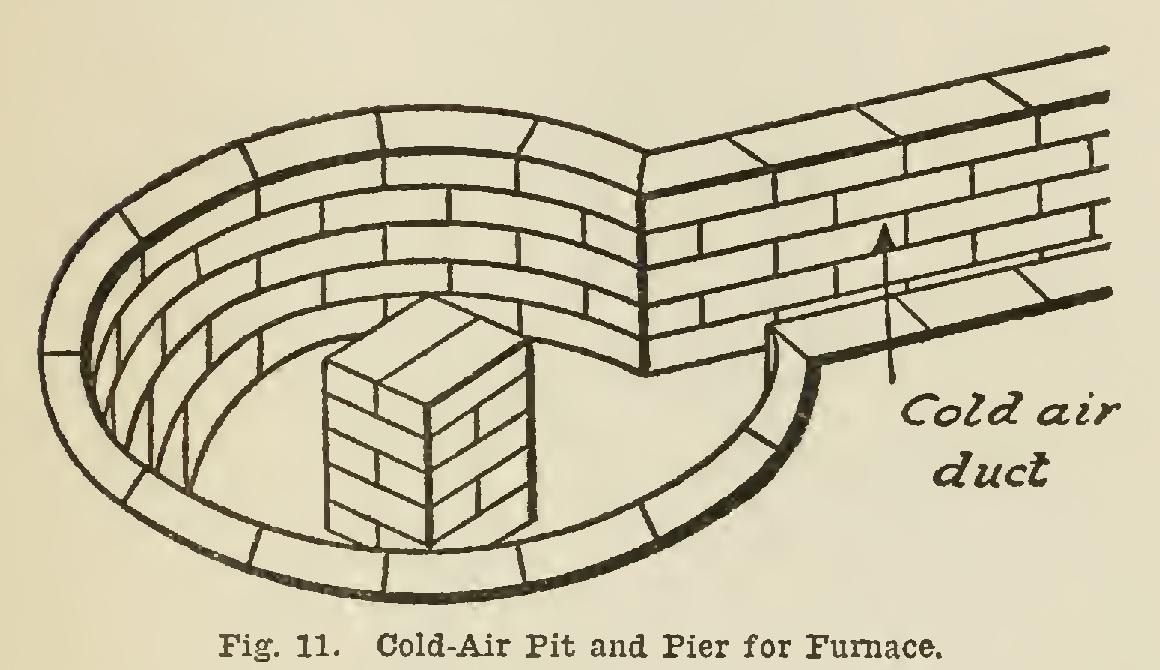

Fig. 10 will illustrate this idea. The outside entrance to the opening should be protected with a coarse wire screen fastened in a permanent manner. We favor the building of a cold air pit of brick beneath the furnace, as illustrated in Fig. 11.

In size, the cold-air duct should have three fourths of the area of all heat pipes leading from the top casing. For example, let us assume a job having: One 8-inch heat pipe, capacity 50 sq. in.

Two 9-inch heat pipes, capacity 126 sq. in.

Three 10-inch heat pipes, capacity 234 sq. in.

Total 410 sq. in.

Here the total area of the heat pipes is 410 square inches. Three-fourths of this total capacity is 307 square inches; therefore the dimensions of the cold-air duct should be 12 X 25 inches = 300 square inches.

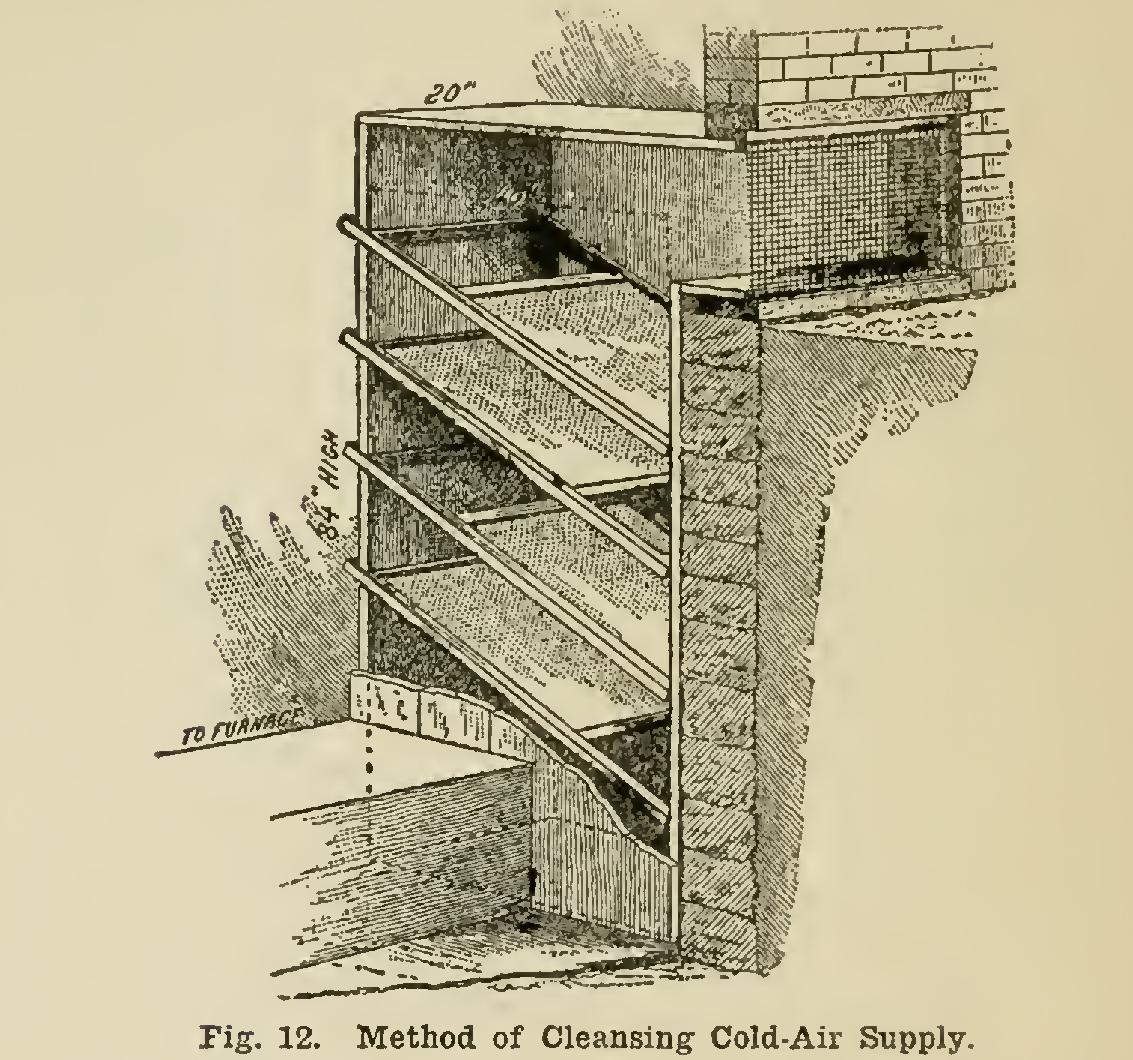

Cold-Air Cleansing. In some localities, such as factory districts, or in places where soft coal is extensively burned, it is desirable to cleanse the cold-air supply prior to its admission to the furnace. A simple method for accomplish

ing this desired result is illustrated in Fig. 12. Frames partially covered with cheese-cloth are inserted in the cold-air chamber or reservoir. These frames are set at an angle of about 30 degrees, the clear openings through them being "staggered" or located on alternate sides of the chamber, as shown. They should be fitted in grooves, and so made as to be easily removable for the purpose of cleaning or re-covering. This simple arrangement will be found very efficient.

Furnace Ventilation. The air we breathe contains more or less carbonic oxide—a poison ous gas which, within a crowded room, is present in the air to such an extent as to cause the occupants headache and other similar ailments. This contamination of the air is caused by the poisons given off in the exhalations or from the bodies of the people within the room. Therefore, by reason of its effect upon the phys ical body, proper ventilation is of even greater importance than heating, and is consequently an essential and inseparable part of the heating problem. It therefore calls for at least some brief pertinent In winter, rooms should be ventilated by taking out air at or near the floor. Taking out air from the top of the room for ventilation is wrong in principle, and always interferes with heating the room. An excellent plan to venti late a residence is to build a large ventilating shaft instead of the usual chimney flue. Up through this shaft, run a tight terra-cotta or metal smoke pipe to carry the draft of the fur nace. The space in the shaft around the smoke pipe is ventilating space, which will be warmed by the draft of the furnace, causing a strong upward current of air in the shaft. A pipe or duct of any form or shape or material that may be found most convenient should be run from the floor or baseboard of each room to this upright ventilating shaft. In this way the lower strata of air will be drawn off from the rooms, and a constant and reliable change of air will be assured. The ventilating register in each room should have about sixty per cent of the capacity of the heat register through which hot air is supplied for heating the room. This method of ventilation is comparatively inexpen sive, if put in at the time the house is built.

Where there is no mechanical device for forcing ventilation, the main ventilating shaft must be warmed so that there will be maintained an upward current of air in it; a cold ventilating shaft is worse than none at all. It is easier to heat rooms that are properly ventilated than to heat them when there is 110 provision for sys tematic ventilation. In a properly ventilated house, the colder and impurer air is being con stautly drawn off from the lower parts of the rooms; the fresh warmed air is filling the rooms from the top downward, and this warm air is not working against resistance.

It is extremely difficult and requires an ex travagant consumption of fuel to heat a church or ball with a very high ceiling, without draw ing off the cold air from the lower part of the room. In such cases, where the dealer cannot induce the owner of the building to put in a ventilating shaft, satisfactory results may be attained by supplying the furnace with cold air drawn through a cold-air duct from the room above the furnace; but the usual provision should be made, when this plan is adopted, for supplying cold air from the outside. The duct from the outside and the one from the room above should be joined into one duct before reaching the furnace, so that, by placing a turn damper at the junction, the supply of cold air can be taken from outside, if desired, when the room above is well heated and when there are a number of people in it.