Rules Useful Tables

pipe, feet, table, water, inches and sewer

USEFUL TABLES, RULES, ETC.

The experience of practical plumbers has resulted in the accumulation of a great mass of useful information which has been embodied in the convenient form of ready tables, concise practical rules, etc. We now present such por tions of this accumulated fund of information as will be found of greatest practical value in ordinary plumbing work.

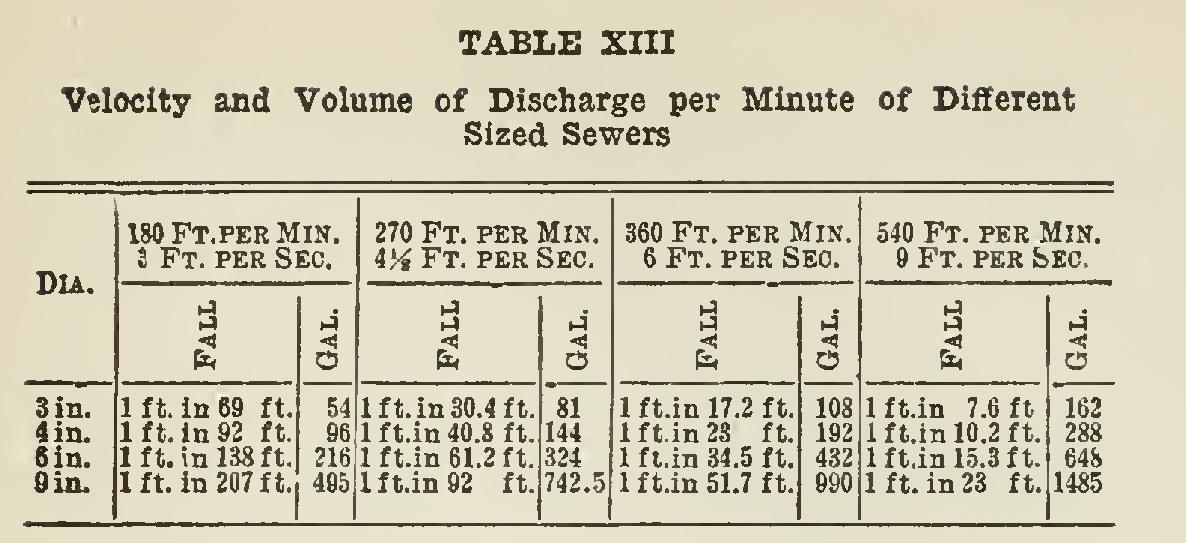

Capacity of Sewer Pipe. The

carrying ca pacity, in gallons per minute, of sewer pipe laid at various grades, is shown in Table IV.

Discharge of Sewer Pipes.

Table V shows the discharge from various-sized sewer pipes laid on a grade of 1 foot in 100 feet.

Size of Sewer Pipes. Table VI shows the size of sewer pipe required to carry off the rain water from various-sized roofs, under average conditions of rainfall.

Sizes of Galvanized-Iron Range Boilers.

The dimensions and weights of both "Standard" and "Extra Heavy" galvanized-iron range boilers are given in Table VII.

Miner's Inch.

A Miner's inch of water about equals 12 United States gallons per minute.

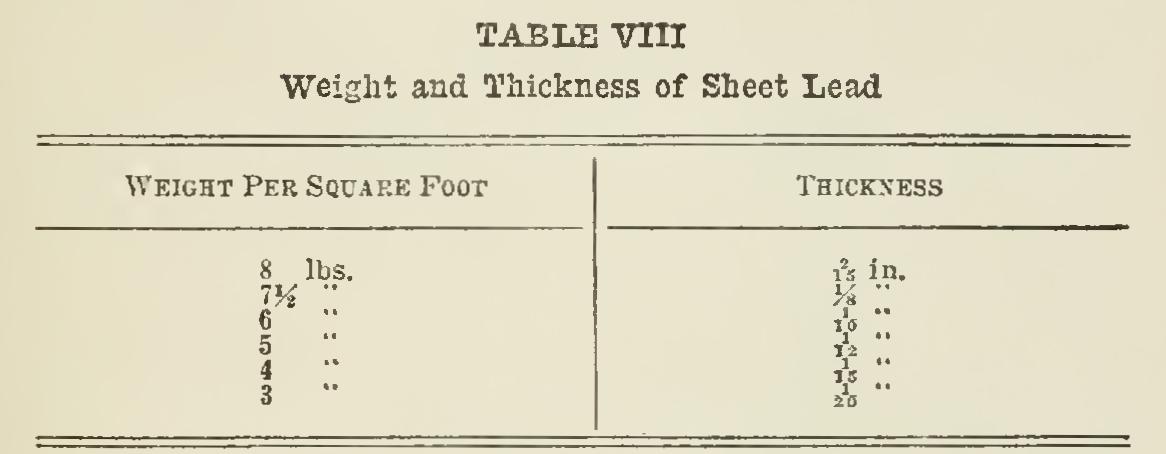

Sheet Lead.

The weight and thickness of sheet lead are indicated in Table VIII.

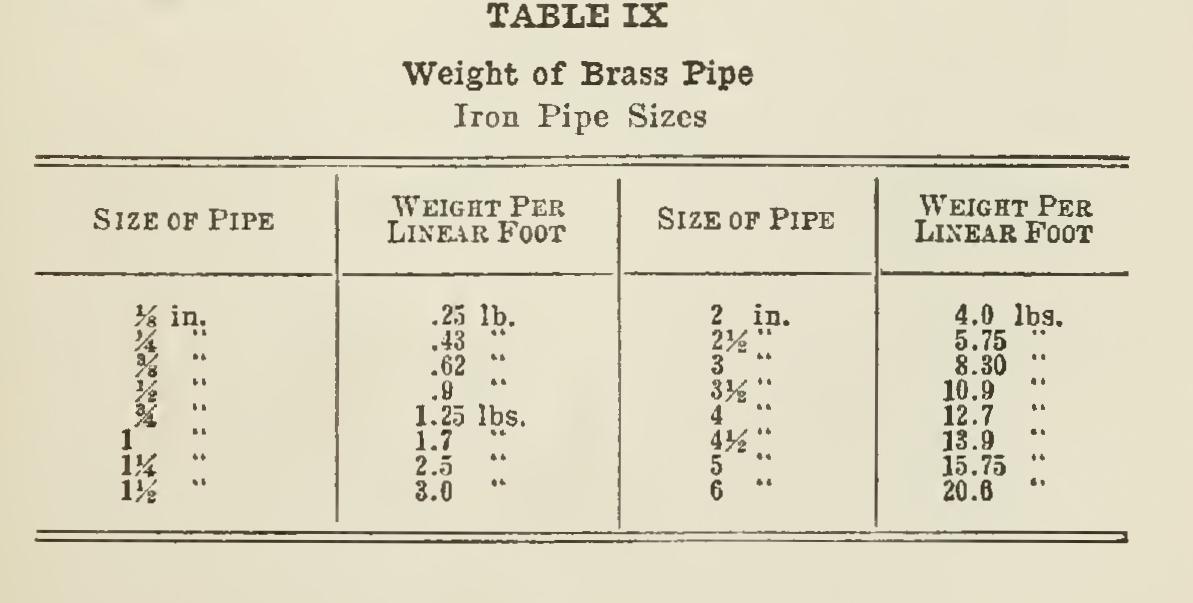

Brass Piping.

Table IX gives the weight per linear foot of brass pipe of standard iron pipe sizes.

How to Make Rust Joints. The following five methods of making rust joints are in com mon use: (a) Measure by weight, 2 parts of Flour of Sulphur, 1 part Powdered Salammoniac, 80 parts Iron Borings. Mix with water to a paste, and apply to the joint that it is desired to make. This sets quickly, and makes a good joint.

(b) Measure by weight, 1 part Flour of Sulphur, 2 parts Salammoniac, 200 parts Iron Borings. Mix with water to a paste and apply. This is longer in setting than the first combina tion, but makes a much stronger joint.

(c) Mix 10 parts Iron Filings and 3 parts Chloride of Lime to a paste by means of water. Apply to the joint, and clamp it in place. This will set solid in about 12 hours.

(d) Mix 80 parts of Iron Chips or Borings, 2 parts of Salammoniac, 18 parts of water to a paste, and apply to a joint. Sets slowly.

(e) Mix 5 pounds Iron Filings, 1 ounce Sulphur, 1 ounce Salammoniac, with water, to a paste. Apply to joint. Sets in from 3 to 5 hours.

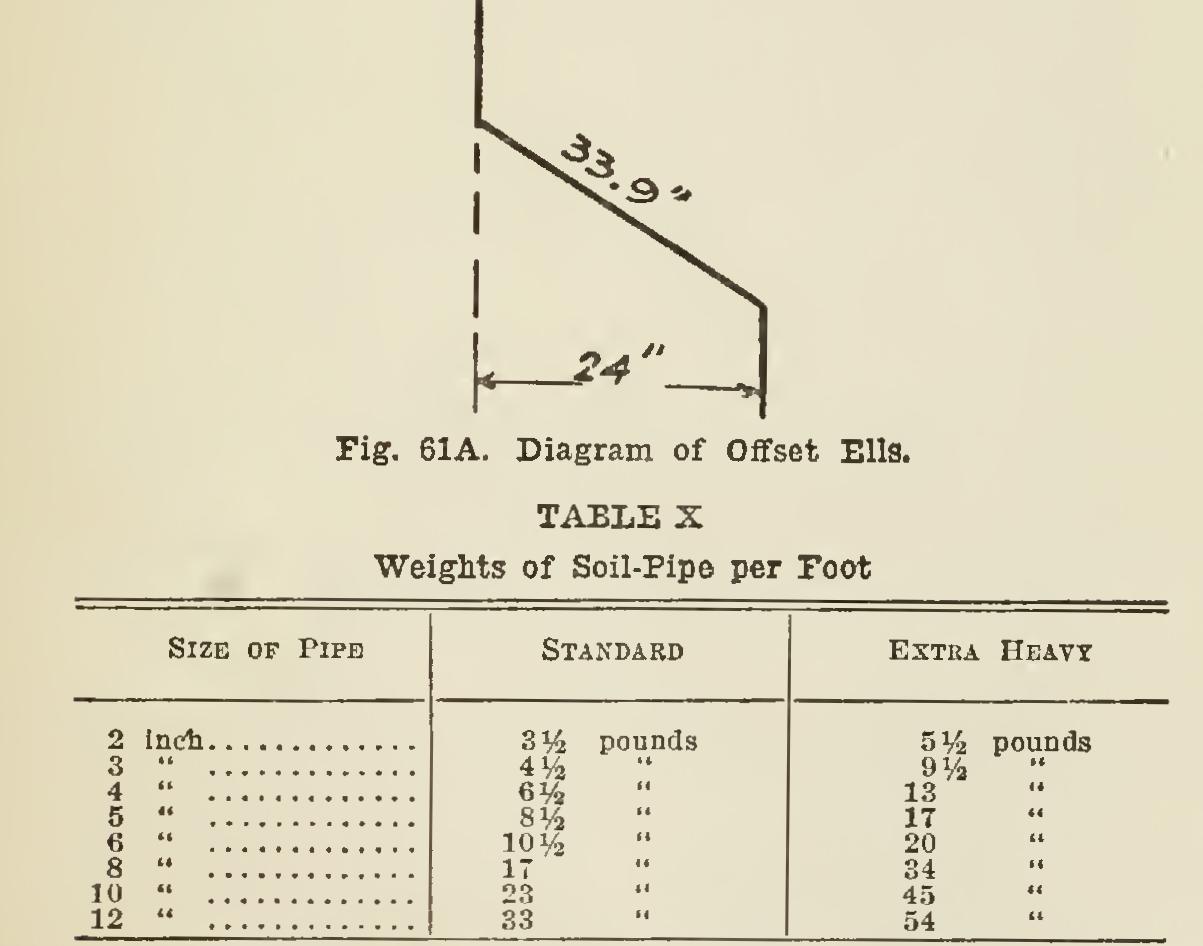

To Find Centers between Fittings. To find the length of piping required to connect fittings where offsets occur—that is, to determine the distance between fittings, center to center, mul tiply the length of the offset, in inches, by the factors indicated as follows: For 60-degree or 1/6 bends, multiply by 1.1547 " 45- " 1/8 " " " 1.4142 For example, suppose that it is desired to know the length between centers, of two 45 degree ells, when the offset is 2 feet (see accom panying diagram, Fig. 61 A). Since 2 feet=24 inches, we have: 24x1.4142=33.9+, or practically 34 inches, which, allow ing off for the ells, will give the length of the pipe re quired.

Capacity of Storage Tanks. As a basis for figuring the size of storage tank required, we may take the average amount of water used daily by one person, which is as follows: Tanks up to 6 by 22 inches are tapped 1 inch. Tanks up to 10 by 30 inches are tapped 11/2 inches.

Tanks above 10 by 30 inches are tapped 2 inches.

For example, a 6-inch sewer, laid to a grade of 1 foot, in 61.2 feet will have a velocity of 270 feet per minute, or 41/2 feet per second, and will discharge 324 gallons per minute. Other grades and discharges can be similarly figured from the table.

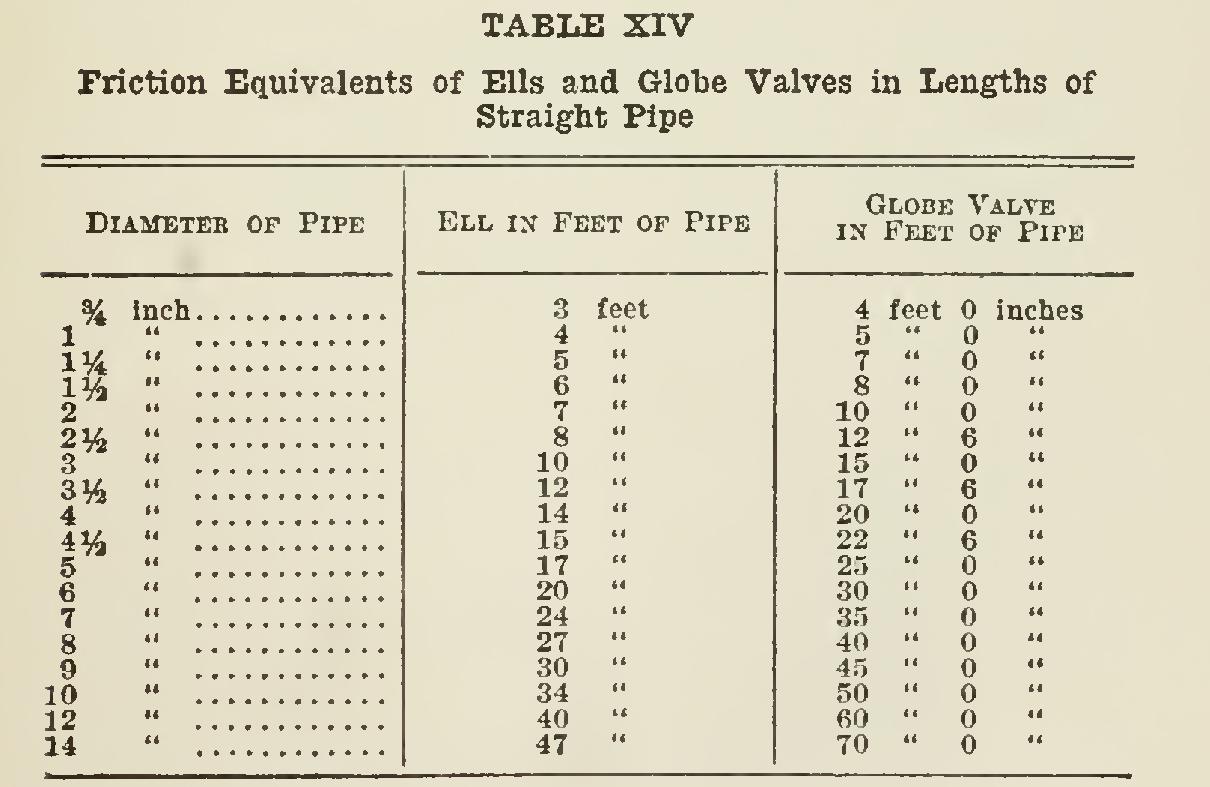

The friction loss caused by ells and valves in pipe work can be calculated from the data of Table xrv.

If, for example, it is desired to know the fric tion loss in a line of piping, caused by 2 ells and 1 valve, the size of pipe being 4-inch, by refer ring to the table, it will be seen that one 4-inch ell is equivalent in friction to 14 feet of pipe, and the 2 ells would therefore mean 28 feet, which, with 20 feet for the valve, would make a total friction equivalent of 28+20 feet, or a total friction loss equal to the friction loss in 48 feet of 4-inch pipe.