Manufacture of Brick

clay and cement

MANUFACTURE OF BRICK The word "brick" as commonly used, is understood to refer to blocks of clay molded to required shape and size by hand or machine. Until recent years, all bricks were made of clay. The manufacture of blocks of similar size and shape, from sand and lime and cement, has brought into the market sand-lime brick and cement brick. Of these two kinds of brick the sand-lime brick has been adopted by the clay-brick men, owing to some similarity of material and a marked resemblance of manufacturing processes. The cement brick, on the other hand, has materials and manufacturing processes resembling those of cement blocks and other cement products; and a consideration of their use and suitability for specific work will be found in works devoted to cement subjects.

A well-understood commercial classification of clay building brick is: Common brick, Face-brick, and Firebrick. Common brick are brick used for ordinary exterior and interior construction. Face-brick have a name that is selfexplanatory, and include the best bricks of all types made by various processes and machines, whether soft-mud, stiff mud, dry-press, sand-lime, paving brick, or firebrick (when the two last named are used for building purposes in wall construction). Firebrick are used wherever there is a fire hazard, as in chimneys, flues, fireplaces, etc.

Brick of all three classes mentioned above, are made by three different manufacturing processes—namely, the soft-mud, the stiff-mud, and the drypress.

Soft-mud brick are manufactured either by hand or by machine. The clay is dug from the clay bank, and thrown into pits about 6 ft. deep and 8 by 12 ft. in area. The pits arc hued with planking. In the pit, sand is added if needed, and sometimes sawdust, coal dust, or screenings, to assist the brick in burning. Water is turned onto the clay, which is left to soak for 24 hours. In hand yards, the mixing is done in a circular pit by means of a tempering wheel operated by sweep and horse. The clay is. thrown into molds so as to fill them completely and evenly, an operation requiring both strength and skill.

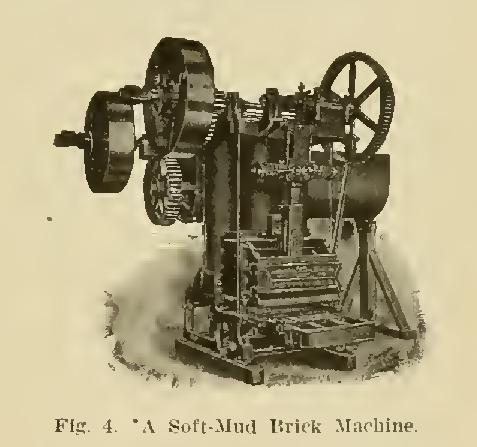

In the manufacture of soft-mud brick by machinery, the clay is taken from the pit and delivered by belt or barrow to the top of the soft-mud machine. A vertical shaft equipped with knives, in revolving, mixes the clay and forces it down toward the molds, to which the clay is then delivered by horizontal blades, an up-and-down plunger ramming the soft mud firmly into the molddivisions. The mold is then removed,

and the surplus clay "struck" from it, another mold replacing it immediately and automatically. The brick from the mold are emptied onto a board or "pallet," and are borne thereon to the drying ground, shed, or building.

When the molds are dipped in water to prevent the brick from sticking, the product is known as "slop brick." When they are dipped in sand for the same reason, the resultant brick are termed "sanded" brick. Slop brick are deficient in color, in many slays; and in all cases have smoother surfaces than ordinarily found in soft-mud bricks; they also have rounded edges and corners. If the sand used with the sandstruck brick is selected for the purpose, as it generally is, the surface of the brick is neither marred nor enhanced by the sanding.

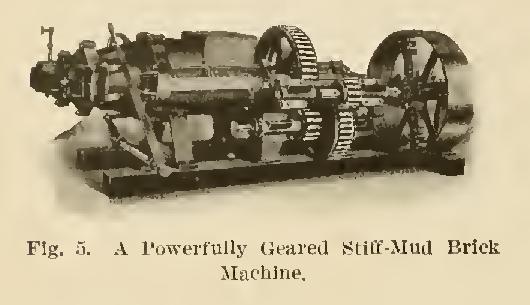

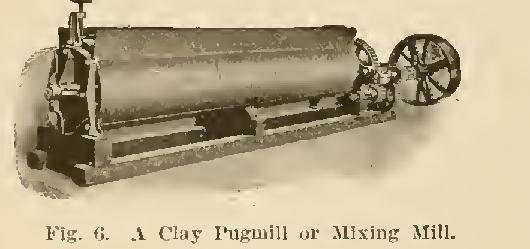

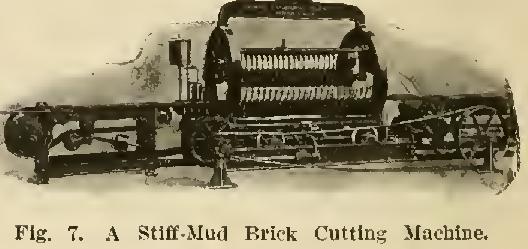

In the stiff-mud process of manufacturing brick, the soakmit is eliminated. With less water, time and fuel are saved. The preparation of the clay is accomplished by means of crushing and disintegrating machinery, known as pulverizers, crushers, rolls, etc.; and then water is added during the passage of the ground clay through the length of a pug-mill or mixing mill. ing knives in this mill, pug the clay to a rich, stiff mud, and pass it forward into the brick machine. This contains an auger and auger-knives. The knives feed the clay to the auger, which presses it out in a clay column through the die quired; and arc cored to make hollow at the mouthpiece of the machine. The desired, according to the product dies are made to any shape and size brick, block, or fireproofing tile. The clay coltunn is received by a special cutting table, upon which the bar of clay, while in motion, is cut to the proper size by wires. If the width of the column is the width or thickness of the brick, then the cut is made at the ends of the brick, and they are called end-cut. If the width of the column is that of the length of the brick, then the cut is made at the sides of the brick, and they are known as side-cut. The brick are removed from the cutting table by an off-bearing belt, from which men. load them on trucks or ears for the driers. The mining of the clay for stiff-mud brick is done by digging, by scraper, or by steam shovel, according to the character of the clay and the capacity of the plant.