Manufacture of Brick

clay and dried

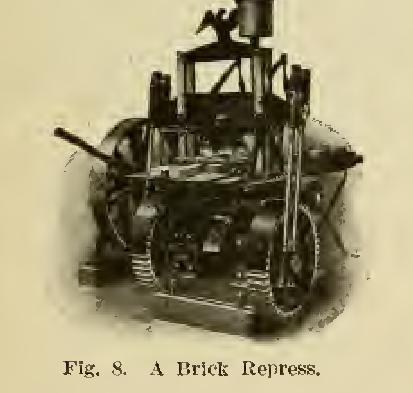

Re-pressed bricks are stiff-mud or soft-mud brick that have been repressed in a special plunger-and-mold machine, with molds slightly larger than the brick, allowing for adjustment in the formation of sharp corners and edges and smoother faces. This method is used for securing a special stock of face-brick, and removes the roughness caused by the wires in cutting the stiffmud brick. In spite of many arguments claiming increased density, impermeability, and structural strength, tests have not revealed such advantage, and the gain by re-pressing is in appearance only. Soft-mud brick are re-pressed after they have dried out considerably and can be handled iu safety. Few softmud brick are re-pressed (most of them being firebrick), in comparison with stiff-mud re-pressed brick.

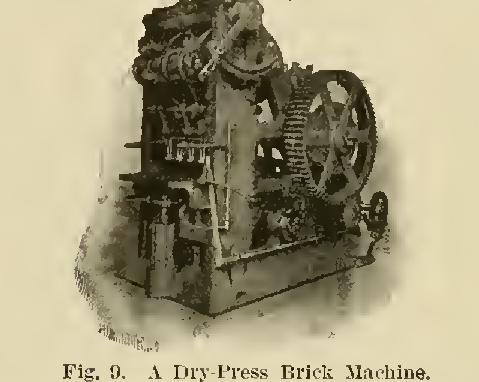

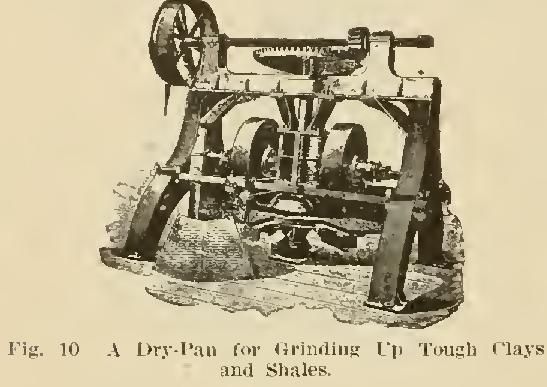

The dry-press process of manufacturing brick has produced the highest grade of building brick, when form, color, and strength are considered in combination. The clay used contains only 5 to 8 per cent of moisture. It is mined by hand, by scraper, or by steam shovel. It is generally stored in huge sheds so that a dry supply may always be available, no matter what the weather conditions, and also for the gain to the clay by weathering and "aging." Sometimes it is taken direct to the dry pans. In this machine, huge rolls revolve over a perforated or slotted. base-plate, through whose openings the clay falls into the buckets of an elevating belt. These buckets dump the clay onto a screen above, which passes the fine particles, the coarse ones returning to the dry pan. The screened clay is again mixed, and then fed to the molds of the dry-press machine. In this, a charging device carries the clay over and into the steel molds, whose bottom sides cinisist of plunger-heads. When the charger is out of the way, upper plungers descend and till the molds. Thus the clay is subjected to enormous pressure between the upper and lower plungers. At the end of the pressure, the upper plungers reascend, and are followed in their motion by the lower plungers, which push the formed brick to the top of the molds. The brick are removed to brick barrows, and the operation is repeated.

All molded and ornamental brick are made in the same manner, the molds being constructed accordingly. If the clay becomes too dry, it is moistened to the proper consistency by a jet of steam before entering the molds.

Dry-press brick do not need to he dried. They can be burned inunedi

ately after molding. Only in special cases are they dried, and then for the purpose of varying their color in burning. Dry-press brick are made principally for face-brick. With some clays, however, the dry-press process is the most suitable for the manufacture of common brick.

How Brick are Dried. Brick are dried in the open air on the ground, in the open air under roofs and on racks, and in special drier-buildings using direct beat or steam heat to dry out the brick.

The first method is erode and used only in the smallest plants. The second is widely used in small plants operating only during the summer or under exceptional climatic advantages. Artificial drying is, however, the most favored, the most economical, and insures speed and uniformity of production. In artificial driers, the moisture expelled by the heat is removed by tall stacks or by induced draft. The heat is also frequently introduced by fan and distributed by Hues.

When dried by nature, brick require from 5 days to 3 weeks for drying. Artificial driers generally accomplish the result in 24 to 30 hours.

How Brick are Burned. The burning is the crucial test of clay quality and human skill. Brick, perfect in shape and composition as they emerge from the drier, may be ruined in color and shape by mistakes in the firing. Under the action of fire, clay loses plasticity, and its particles are fused together in enduring form.

Brick are burned in kilns, of which there are three main types—up-draft, down-draft, and continuous.

Up-draft kilns are either temporary or permanent. Temporary up-draft kilns are formed of the dried brick themselves, built up in piles 30 to 50 ft. long, 20 to 35 ft. wide, and from 12 to 18 ft. high. In beginning to build the pile, the lower half is constructed in the form of a series of arches stretched clear across the kiln. Above these arches, the brick are set solid. The arches are designed to carry the fire clear through the kiln. As a general thing, the fire is started with wood, and finished with coal; but where wood is cheap, that fuel is used throughout. Firing is also sometimes done with coal entirely. The heat in the arches rises upward through the body of the kiln; hence the name "updraft." The outside walls of the kiln are daubed with mud to retain heat, and the tops are also filled over. The entire kiln is torn down at each burning.