Manufacture of Brick

kiln and heat

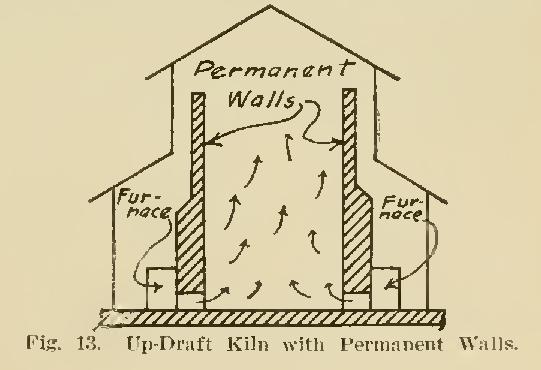

Permanent up-draft kilns have permanent walls and firing places. The walls are from 12 to 16 in. thick, and the brick are laid in mortar. The fuel is confined to the furnaces, only the flames and the heat entering the kiln. The tops of these kilns are formed, of "platting," consisting of burned bricks sealed with mud. This covering is the only part of the kiln removed after each firing.

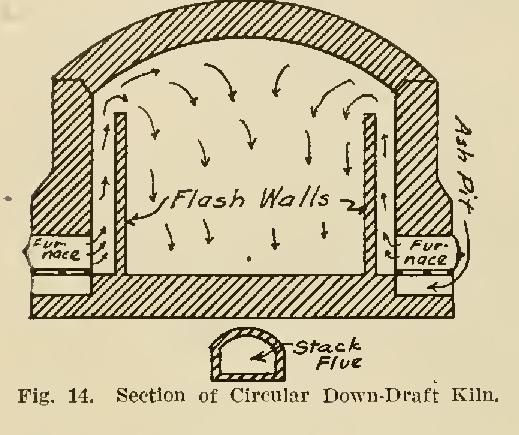

Down-draft kilns are built circular or rectangular, and have permanent walls and roofs. A type of the circular down-draft kiln is shown in the section in the illustration (Fig. 14). As will be noted, the heat is generated in the fire-boxes, and passes into the kiln through the vertical flues or "bags." Striking the roof, the heat is then drawn down through the brick, through openings in the floor, into the stack flue shown beneath the kiln, which leads to the main chimney. In all down-draft kilns, there are many variations in flue and floor construction, but the down-draft principle is the same.

A continuous kiln is a 'series of downdraft kiln chambers arranged' in a continuous and circular manner. The heat is continuously maintained in some sections of the kiln. The most common form is that of two parallel tunnels connected at the ends. The firing in the first section is started by means of a tempotary furnace in the side of the chamber. After the heat has been raised, the side is closed, and further fuel is fed down into the brick through vertical flues built while setting the brick in the chamber. When the brick in a chamber have finished burning, their cooling heat is not wasted as it is with the up-draft and down-draft kilns, but is led into the next chamber to start the firing of the brick therein. Each chamber has small holes in the top, provided with iron covers, through which slack coal is fed in small quantities. In continuous kilns, there are always some sections being filled, some burning in different stages, and some being emptied or "drawn." To pull the fire from section to section in this way, requires a powerful draft; and this is generally furnished by a tall stack.

Economy of fuel and uniform excellence of production are claimed to be the chief advantages of this form of kiln. The initial investment is great as compared with the down-draft or updraft types.

Semi-continuous kilns partake of peculiarities of construction of both down-draft and continuous. In tunnel

kilns, the brick are set on cars, which form the bottom of the tunnel and tightly seal it. The fire is always at the same place, and the brick are carried on the cars toward the fire and through it, the brick cooling before they reach the tunnel-end. Only a few kilns of this type are in operation in America.

The burning of the brick may be divided into three stageswater-smoking, half-fire, and full fire.

The water in the brick is slowly driven off by gently raising the heat in the kiln during the water-smoking stage. As long as steam or "watersmoke" is seen escaping from the top of the kiln or from the chimneys or stacks, a low heat must be maintained. When this has disappeared, much of the danger of checking and deformation has passed. The fire is then raised with greater speed, depending on the nature of the clay. When the red glow is seen to be uniform throughout the kiln by means of the peep-holes, firing is then carried steadily on to the end. If carried too fast, the fire will melt the brick The burning of brick usually requires from 5 to 7 days, according to the clay used.

Paving Brick. "Paving brick" was formerly the name given to any very hard, ordinary brick suitable for paving purposes. The development of the together. Shales and fireelays stand a much higher heat than ordinary clays. Paving brick made from shales are raised in the kiln to a degree of beat in which they are vitrified, and become as glass, practically impervious to moisture. Great care is taken in their cooling so that they may anneal and possess the requisite toughness.

paving-brick industry, however, since 1890, has set a standard through more complete tests than given to any other clay product, in which vitrification and toughness are qualities which must be possessed by the paving brick or block. Because of their extremely low absorption and their toughness (insuring small loss in handling and shipment), and also because of their dark color, resembling brownstone, paving brick and paving block have become popular as a building material. They are principally made from a shale clay by the stiff-mud process. Paving brick and block are favored not only on account of their color, but also because they are not subject to efflorescence, they are not attackable by acids or gases, and every rain washes their exposed faces clean.