Manufacture of Brick

firebrick and fire-clay

Paving brick in their manufacture follow the same course as other stiffmud products. Owing to the toughness of the shales from which they are manufactured, the machinery used is of the most substantial character.

Firebrick. Firebricks are made principally from a mixture of raw flint clay and plastic clay. There are as many kinds of firebrick as there are uses therefor. They may range in price from $14 to $100 per thousand.

In building ordinary residences, no very high temperatures are to be provided for; and a well-made firebrick of ordinary grade and price will meet all refractory requirements.

Firebricks are manufactured by all three processes—soft-mud, stiff-mud, and dry-press. It is maintained by experts in the manufacture of refractories, that the soft-mud hand-molded brick is the most perfect product.

_Firebricks should have an open grain, and should be porous so that they may absorb and lose heat rapidly. Their composition should be homogeneous; they should be regular in shape and uniform in size.

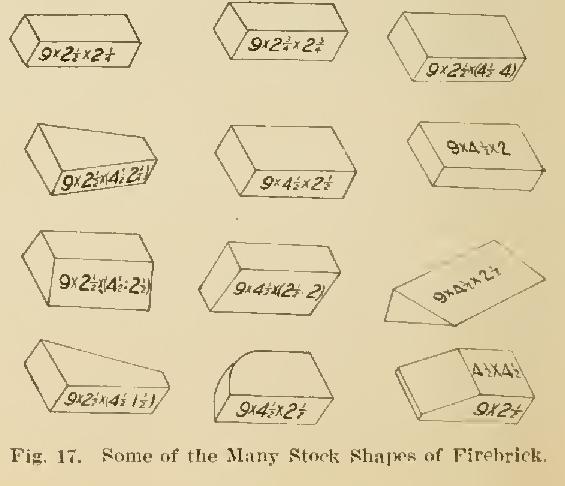

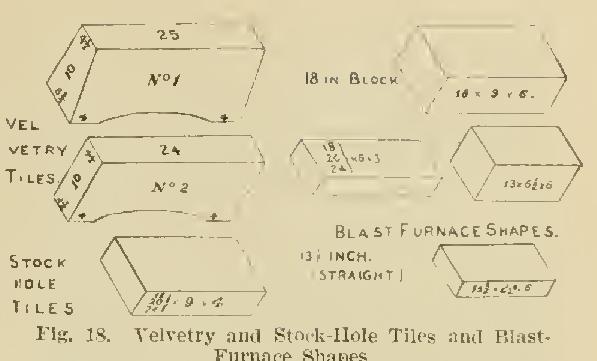

Firebricks in color are cream, yellow, or brown. They are made in immense variety of sizes and shapes, to meet Special commercial applications. The size of the ordinary firebrick is 9 by 41/2 by in., and its weight approximates 7 lbs.

Firebricks which are to be exposed to heat should be laid in fire-clay. The mortar joint should be very thin, and the brick thoroughly wetted before laying.

Fire-Clay. A good fire-clay contains from 50 to 80 per cent of silica, and from 18 to 35 per cent of alumina. It should have a greasy feel, and be of uniform texture.

Fire-clay is not a cement. It is of practically no value as a binder. Its only mission is to fill the voids, and prevent the passage of hot gases or flame. The most perfect firebrick joint is the one which allows just sufficient fire-clay mortar to fill the voids without preventing the brick from touching. The proper method in setting firebrick is to dip the brick one by one into a fire-clay mixture of the proper consistency, and rub or shove the brick in to place, driving it home with the mallet until it touches the brick below it.

Fire-clay as a binder has two serious defects. It shrinks in drying, and has no cementing power. The shrinkage can be reduced by mixing with the clay firebrick flour, secured by finely pulverizing firebrick and sifting it. The right proportion would be 5 parts of fire-clay to 1 part of firebrick flour.

Fire-clay may be given a cementing value by slaking into it a small quantity of lime. Measure the clay; and for each cubic foot, allow a piece of lime the size of an eighth of an ordinary straight firebrick. This enables the clay to take a strong grip on the brick.

All firebrick work should receive, when finished, several coats of fire-clay wash.

To lay 1,000 firebrick, there will be required about 700 lbs. of fire-clay.

No firebrick work should be heated suddenly; the moisture should be expelled gradually, in order to make sure of a perfect job.

A 9-in. firebrick contains 100 cu. in. Six 9-in. brick will make one square foot of face wall, and 54 will lay a square yard of face wall.

Glazed and Enameled Brick Although these terms are commonly used to designate any and all bricks having a glazed surface, there is quite a difference in the method of manufacture and the quality of the two products.

A glazed brick is made by applying a layer of clay composition to the surface of the unburned brick which is to receive the glaze, and then covering this layer in turn with a coating of fusible material which melts at a high temperature, leaving a transparent coating over the layer of clay composition. The color of the under coating of composition gives the color to the brick or glazed face.

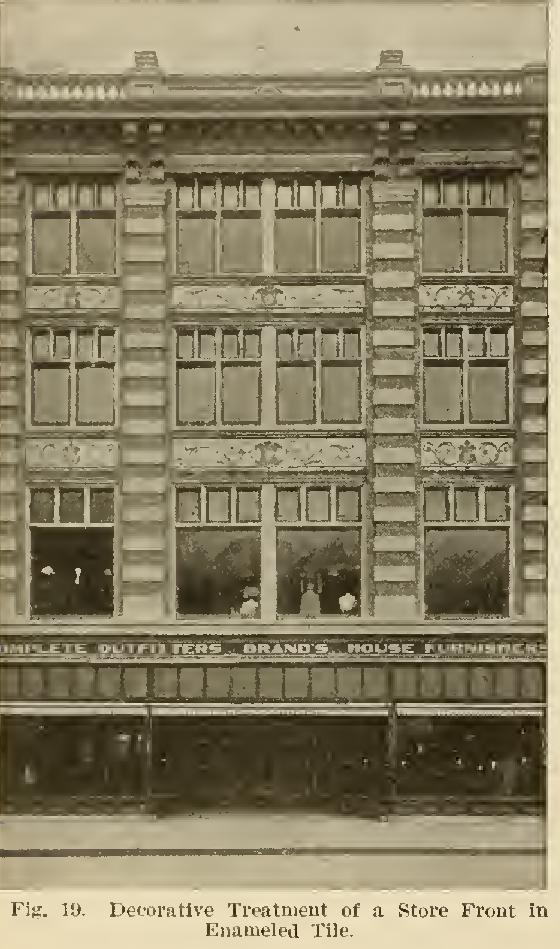

In enameled brick, the fusible enamel coating is placed directly upon the brick, and, in burning, becomes a part of the brick. As a general thing, bricks which are to be enameled contain considerable fire-clay. In this type of coloring, the color is due to the enamel coating in itself.

If it is desired to distinguish between a glazed brick and a true enameled brick, a broken corner readily shows the difference. In the glazed brick, the layer of clay composition shows in the break, while no line will show in the ease of the enameled brick.

The sizes of enameled brick vary from the English size of 9X inches to the size of the standard American brick.

The manufacture of glazed and enameled brick, in their first stages, differs but little from the manufacture of pressed or stiff-mud brick already described. Greater care is taken in the preparation of the material, and also in its selection. The enameled brick obtain their enamel in the firing, from one coating; and this enamel can be applied on either unburned or burned brick. The best results are claimed for enamels fused onto the burned brick.

With the glazed brick, the unburnt bricks are coated with a slip—a mistime of the consistency of thick cream —composed of ball clay, flint, feldspar, and kaolin. This mixture is prepared with infinite care by grindings and puddlings. The brick are covered with the slip on one face, and on one end or one face only. The slip gives the face of the brick the color required. It is necessary that the slip and the body of the brick shall have equal shrinkages under fire action. Over the slip, a thin glaze is applied, which, on fusion, unites with the slip and gives it a transparent, glossy, protective covering.

Most of the brick classed as "enameled," are really glazed brick, as the latter present fewer difficulties and involve less cost in manufacture. The kilns in which these brick are fired resemble pottery kilns, in which the direct flame does not come in contact with the enamels or glazes on the brick. The brick are made in many colors from white to dark green or chocolate, and in bright or dull finish.

Enameled or glazed brick are made in two general sizes: English size, enameled surface 9x3 in., bed in.; American size, enameled surface, 21/4 in., bed in.

Salt-glazed brick are made of any clay that vitrifies. The glaze is given to the brick by throwing salt into the fires in the finishing stages of the burning. Several saltings are necessary.