Lamp

colour, shade, iron, usually, light, heavy, times and vase

Texture of Shade.

Texture, the third element to be con sidered must be very carefully thought out. At times the rough wheel marks on an early glazed pottery are best simulated by using a thin glossy fabric lined with heavily woven crude fabric so stretched that the heavy weave runs on the horizontal. Often soft mat glazes can be simulated by the use of dull crepes over which are stretched a thin chiffon or georgette crepe. These fabrics are useful in approaching the two-tone textures of some glazes such as powder blue, robin's egg souffle, etc. Nothing in a fabric comes closer, if properly treated, to give the feeling of weight and richness necessary in the shading of a fine heavy pottery or bronze than does velvet, but the type of velvet chosen, its density of weave, and its treatment must all be considered.

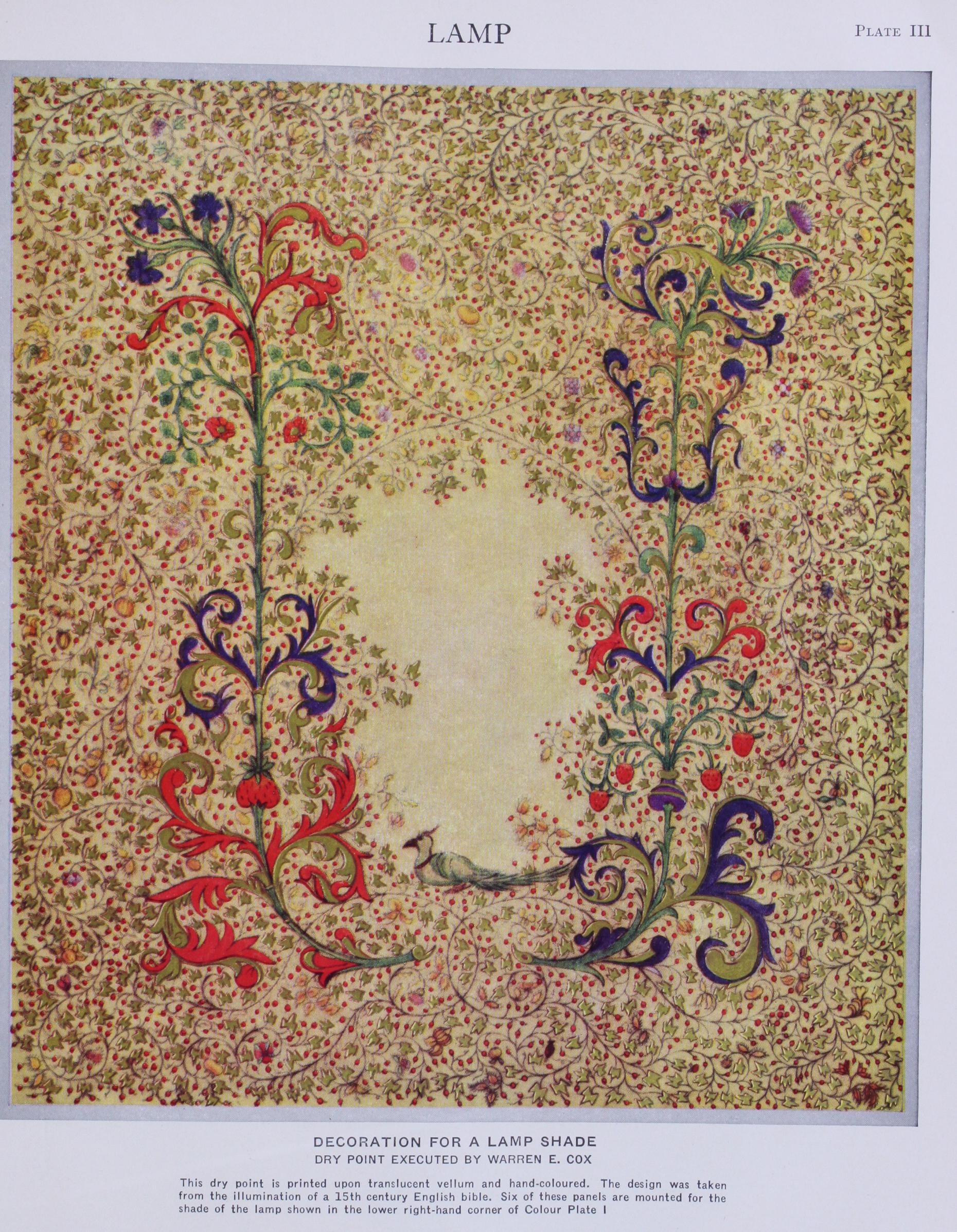

The traditions of old Spain and Italy have taught us the associa tion of vellum with iron, and the slender delicate though strong curves of wrought iron work lend themselves beautifully to the type of curve found in the illumination of old missals. Many other substances such as wool may be used, but as a rule it is wise to eliminate those harsh substances such as glass which are very difficult to make harmonious with any sort of base.

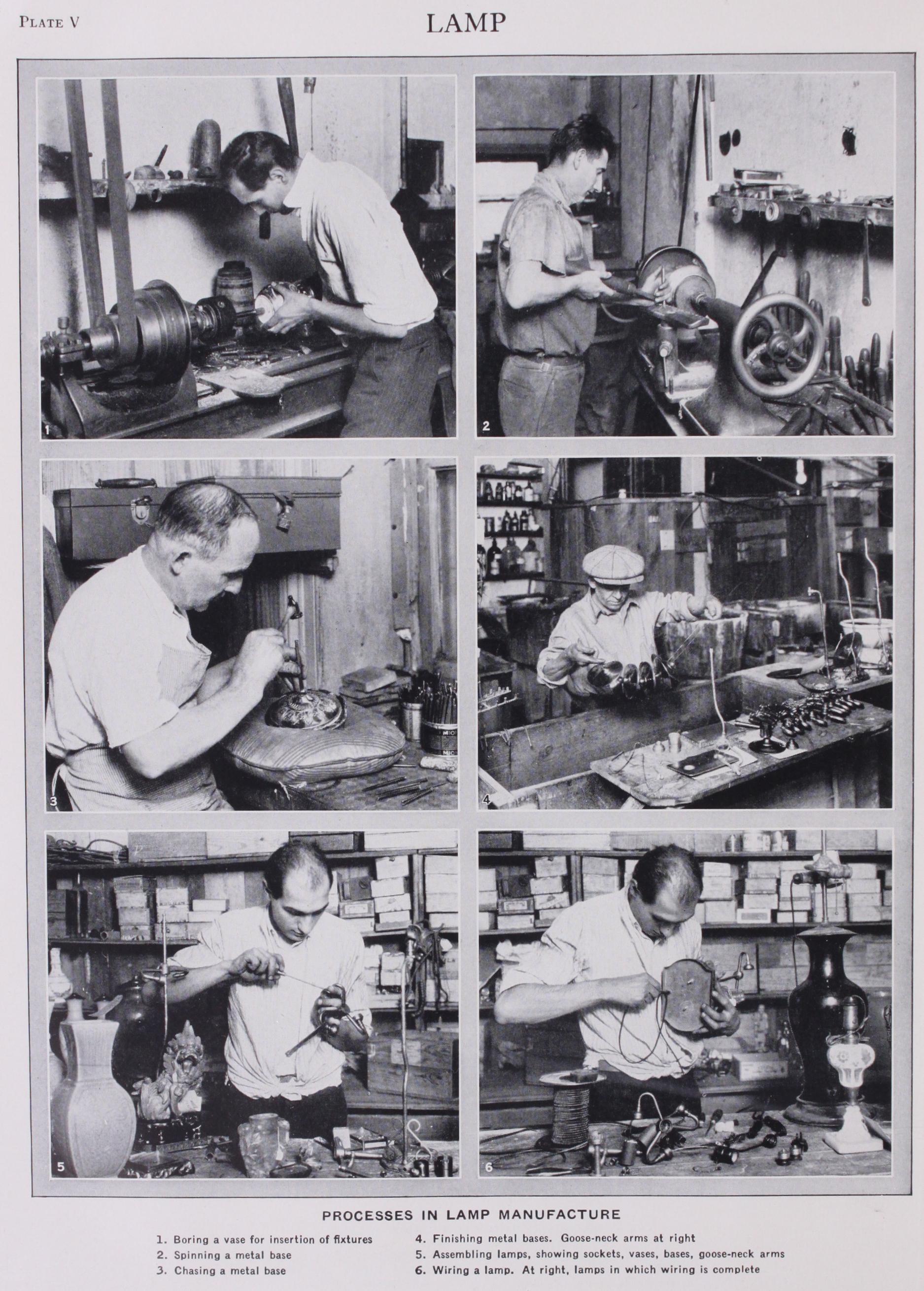

The colour of the vase is as a rule carried up into the shade, but at times the vase may be, as in the illustration colour Plate I., too strong in blue to permit the shade to give the desired light if it were predominant in this colour. Therefore at times contrasted hues are more attractive, and permit a more pleasant colour of light. A careful and conscientious study of the laws of colour is in fact necessary in order to handle successfully colour in the making of lamps. Errors in judgment will be doubly accen tuated when the lamp is lit and not only must the artistic con ception be thought of, but the psychological effect of the colour used must also be constantly kept in mind. (See LIGHTING AND ARTIFICIAL ILLUMINATION ; especially the sections on Lighting Practice.) Mounting.—Modern lamp mounting includes a variety of crafts. Experts with the modern lathe must be able to bore wood or bronze stems, sometimes a number of feet in length, and handle other equipment for the grinding out of holes in the bottom of porcelain and pottery vases. This boring is required in even the most expensive pieces and must be done with a certainty that no breakage will occur. Many bases are spun on the machine lathe over a wooden chuck of the exact shape and size desired.

Afterwards these spun bases may be treated by the processes of repousse, chasing, inlaying, etc.

The casting is usually carried on in large plants and the rough castings finished by hand in the lamp-mounter's shop. These castings, due to the fact that they stand in a bright illumination just below the eye, must be very carefully "cleaned." (For the various finishing processes see SCULPTURE TECHNIQUE ; ORMOLU, etc.) It is necessary to have a cluster of sockets which hold the electric lamps and these sockets should be mounted on either short or long goose-neck arms depending upon the size of the shade. Great care must be taken to have the lamps at the proper distance above the top of the vase so that the reading light will be exactly what is required by the lamp designer (see DESIGN).

There should be an adjustable shade-rest made by a tightly fitting post within a collar which is set with a thumbscrew at various heights, allowing a play of about two inches. This adjustment is not for the purpose of allowing more or less light but for the purpose of slightly raising the shade, if the lamp is placed on a low table, or slightly lowering it, if placed on a high table, in order that the proportions originally designed will be kept constant. The wiring must be carefully done and it is often an advantage to have a small switch-box in the base as well as the pull-chain sockets under the shade. This switch enables one to turn the current on or off with greater convenience.

Shade-making.

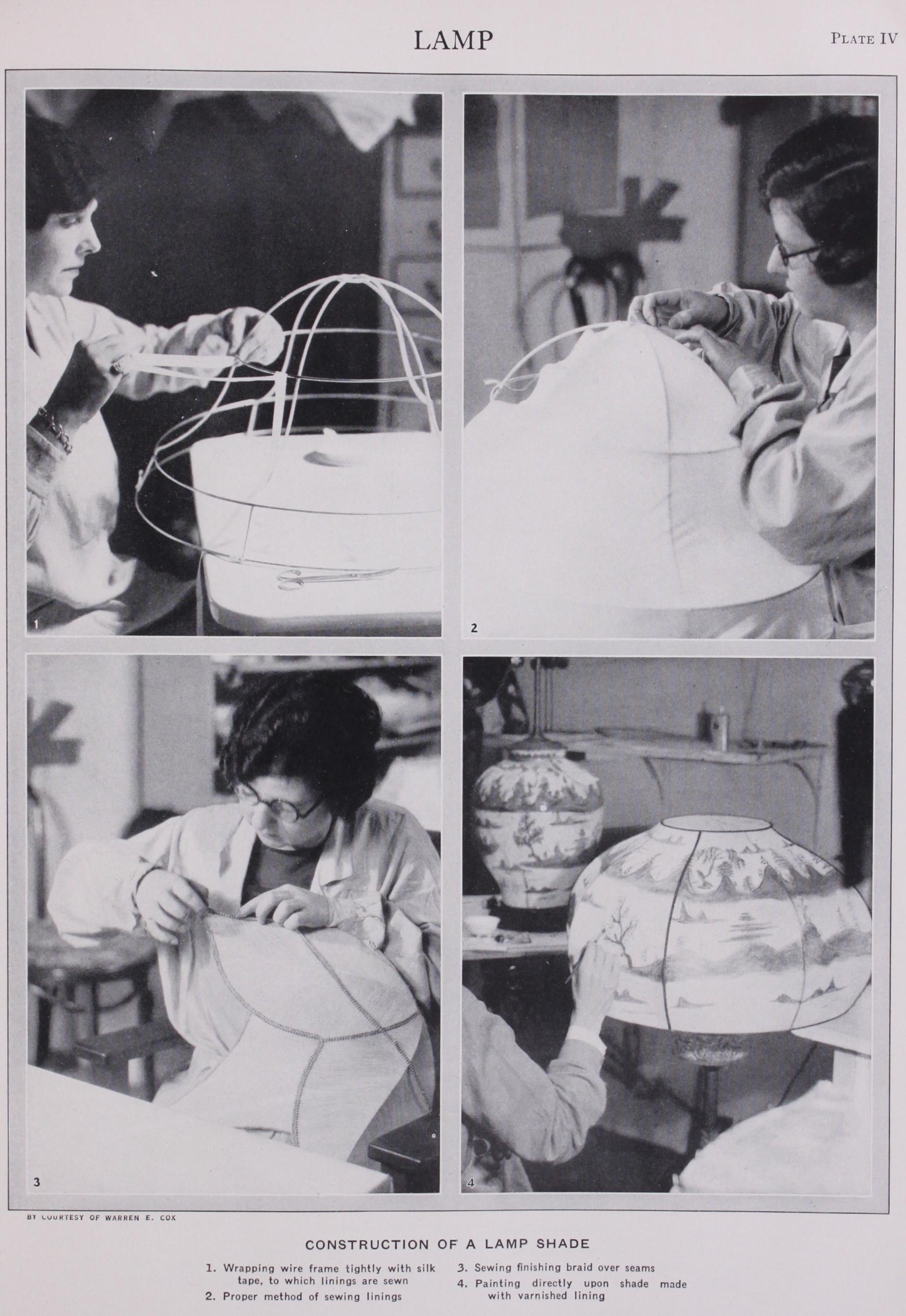

Af ter the design of the shade has been care fully worked out (usually to quarter scale) a drawing in full size is made and sent to the framemaker who specializes in the bending and welding together of wires into the exact forms de sired. These wires are usually bent over rollers of various diameter or made to conform to curves established by the arrange ment of short iron pegs fitting into holes in a heavy iron plate, and the craftsmen who do this work are experts in the art of obtaining the exact curve indicated on the drawing. Not many years ago all frames were soldered together with soft solder but it was found that these frames had large joints which were easily broken and in the modern plants electric welding has taken the place of the soldering process. The shade-rest consists of a heavy washer usually of brass about a quarter of an inch thick which is set within a small ring of wire to which the cover can be sewn and to which it is attached by three or four very short posts.