Details of Construction

fig, door, inches, stairs, usually, riser and stair

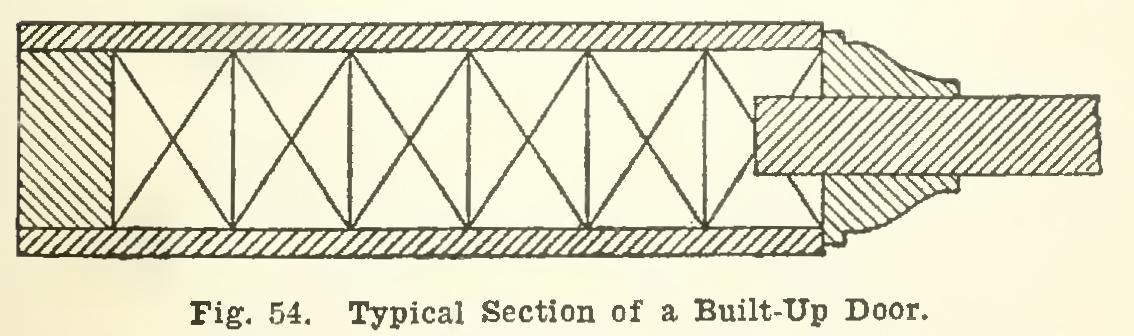

Doors. Doors are of two kinds—the stock door and the built-up door. The stock door is made solid, with a simple bevel called an 0. G. (or Ogee). The stock doors are usually inches, 1% inches, and 13/4 inches thick (see Fig. 53). The built-up door has a core of pieces of pine glued together; this is covered with thin sheets of wood inch thick, called veneer, which is firmly glued to the core. The veneer is made of wood to match the interior finish of a residence.

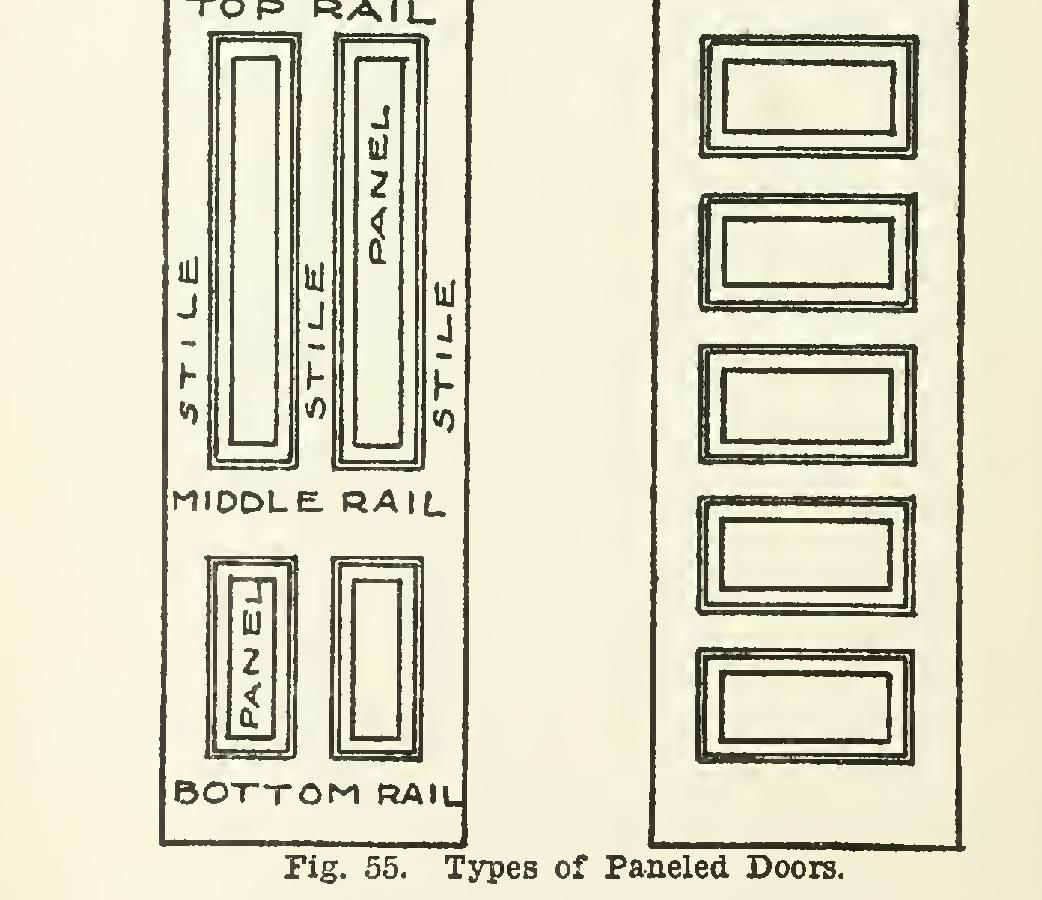

Fig. 54 shows a typical section of a built-up door; and Fig. 55 shows elevations of different doors, with the names of the various parts of a door.

All openings, either door or window, should have the rough framing doubled around them.

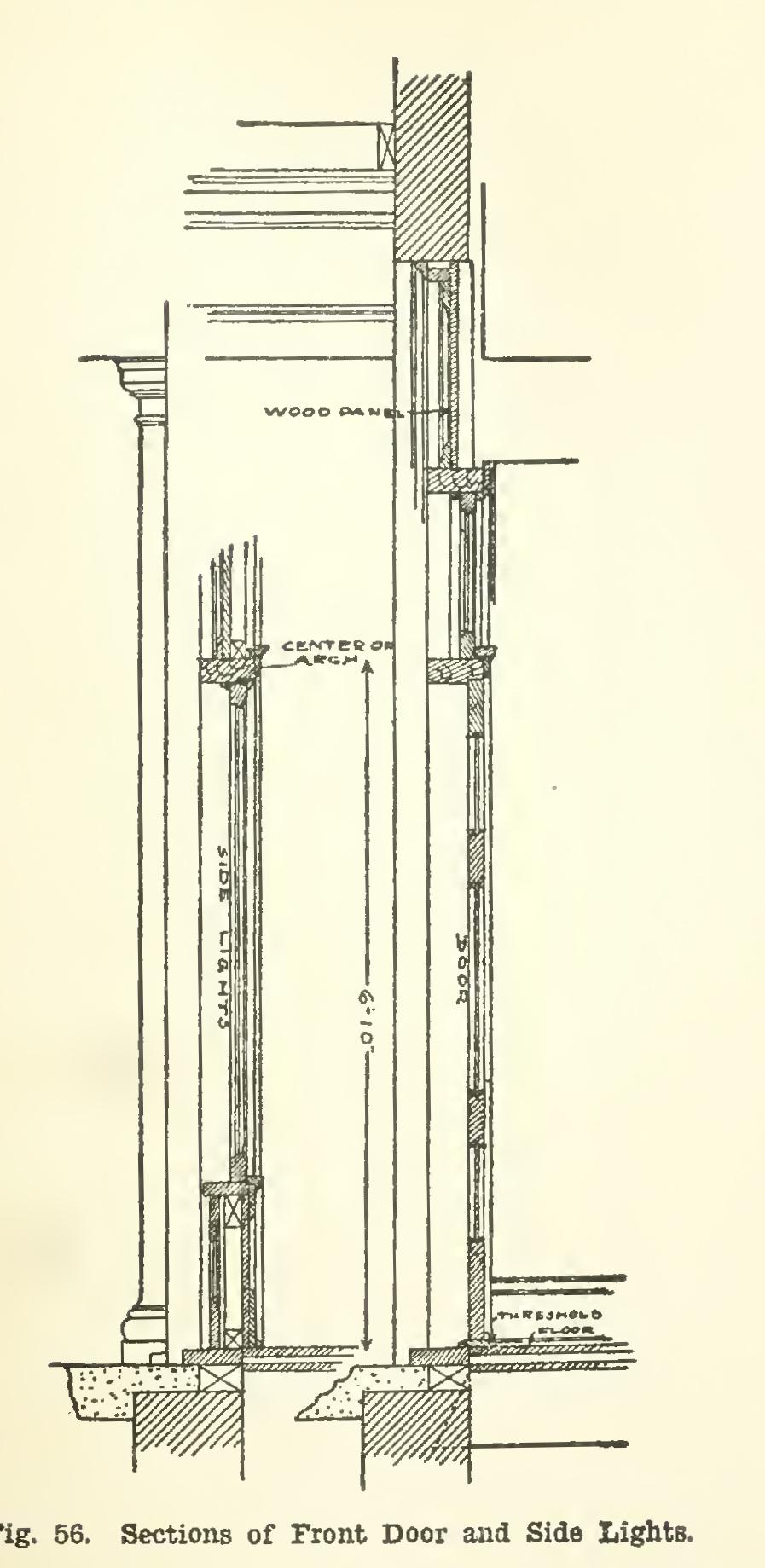

At the bottom of the door we have the threshold, which is a raised piece, usually of oak or some other hard wood. This gives a chance for the door to swing clear of the carpet or rugs. For different details of door trim, etc., see Fig. 56.

The door is hung in a wooden frame which is securely fastened to the framing of the house. The inside and outside casing covers the space between the door frame and the rough framing. See Fig. 56 for a section through a door.

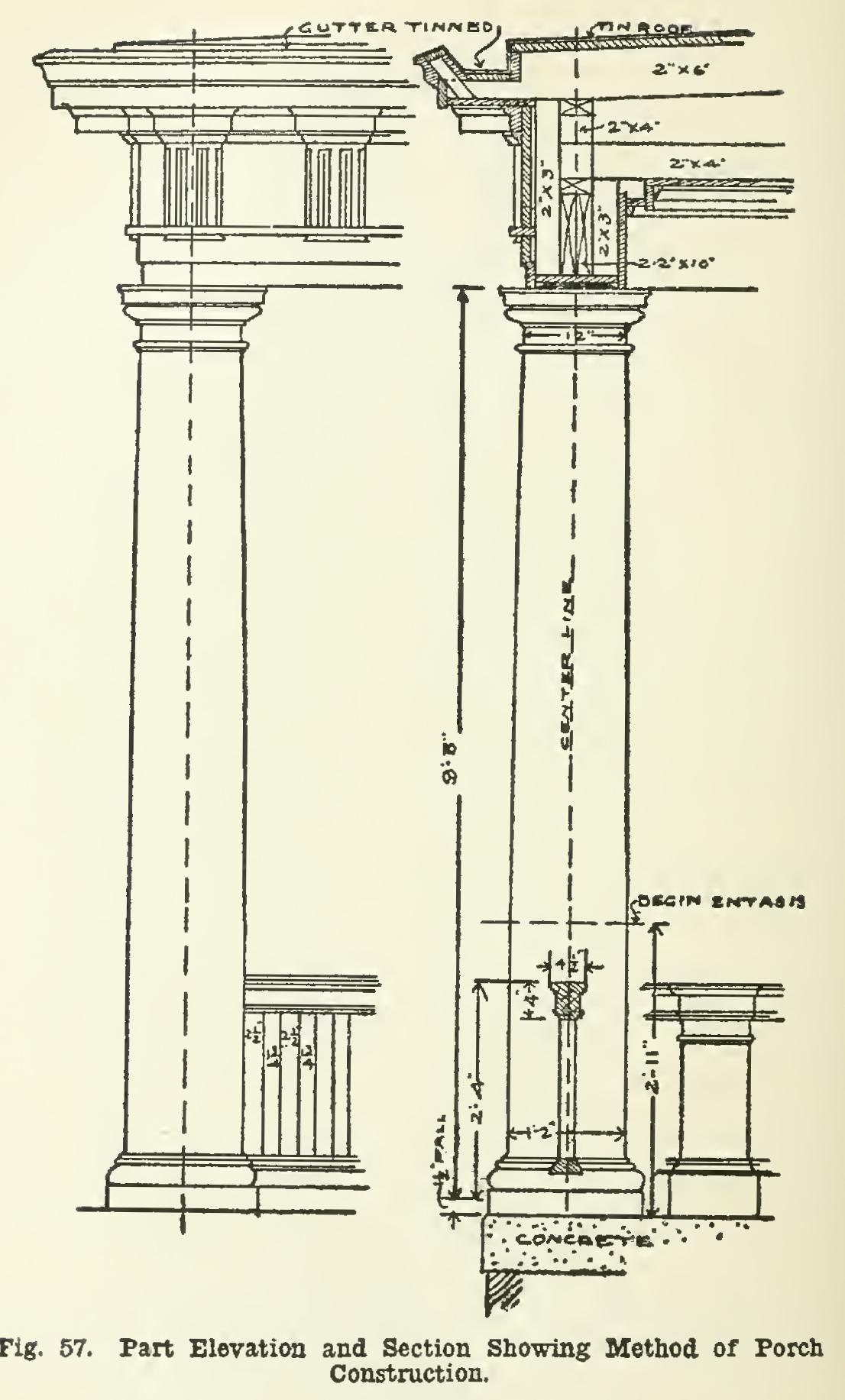

Porch Construction. In Fig. 57 (also Fig.

23), we see a part elevation and a section show ing the method of porch construction. The floor construction will be the same as for ordinary floor construction, except that only one thick ness of flooring is used, and the boards must run at right angles to the house, and have a slight pitch away from the building. This allows the water to drain away from the building. 121 the best construction, the flooring is put together with white lead, thus insuring a perfectly tight joint to keep the water from soaking in at the joints, and thus causing the floor to rot.

Fireplaces. Fig. 58 shows a typical fireplace construction. The flues are all dotted on the elevation. There should be an ash-chute from each fireplace connected to an ash-pit in the basement. There should be a damper in the throat of the fireplace to regulate the draft. All fireplaces should be lined with firebrick.

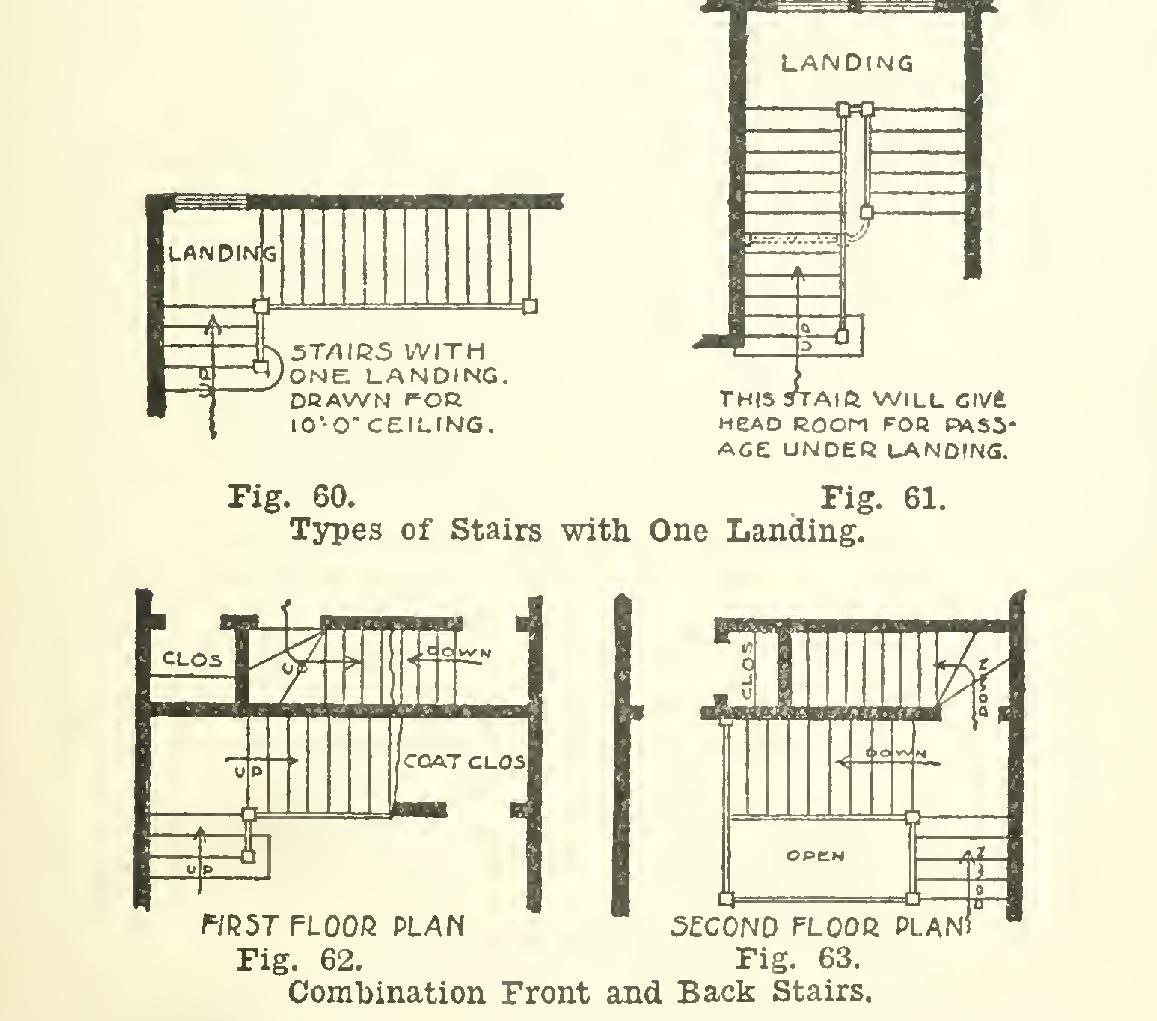

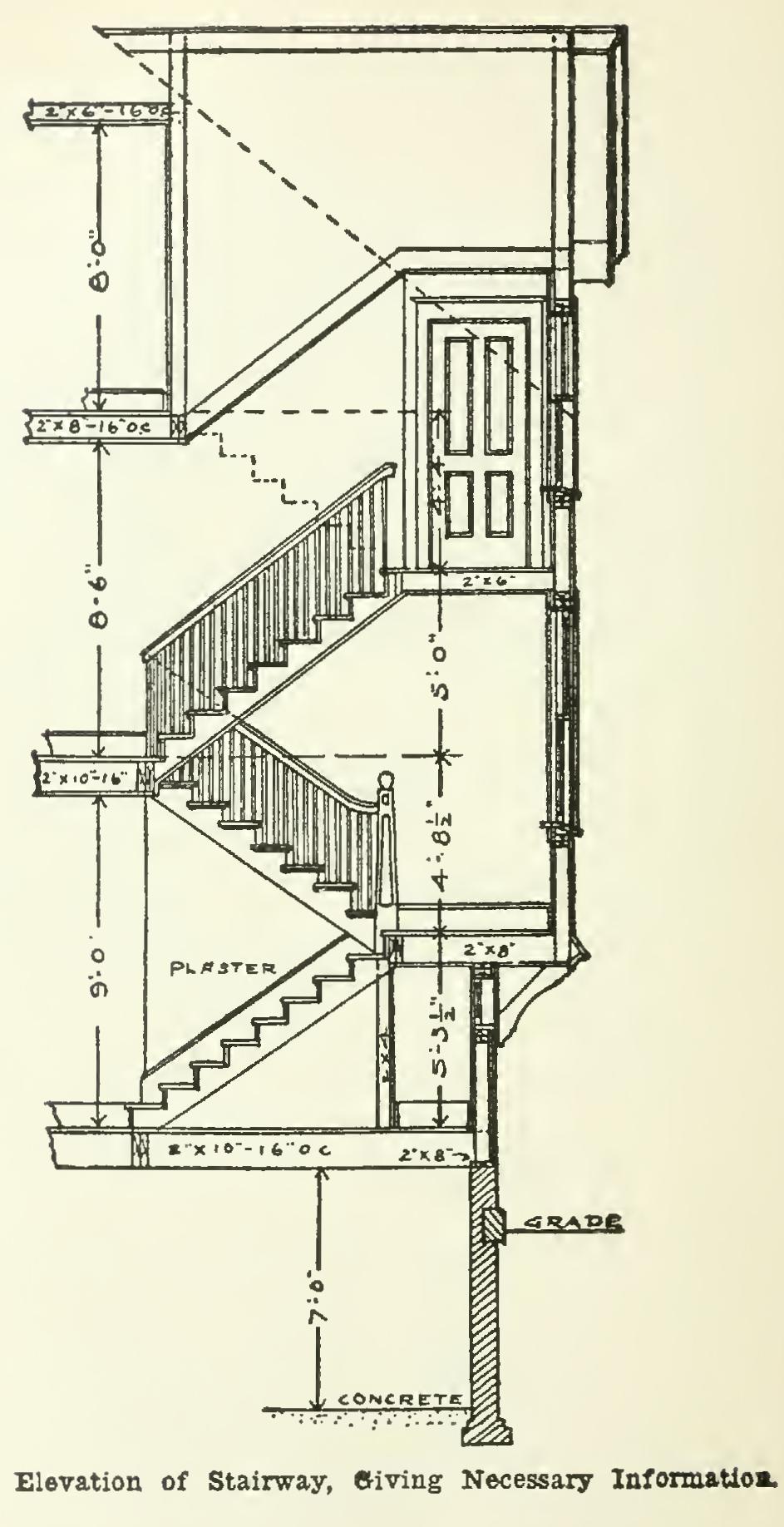

Stairs. For stair construction, see Figs. 59 to 65 inclusive. The simplest stairway is the one that has no turns in it, or the one shown in Fig. 59. As laid out, this stair is for an 8 ft. 6 in. ceiling. Should the ceiling be higher, other

risers may be added.

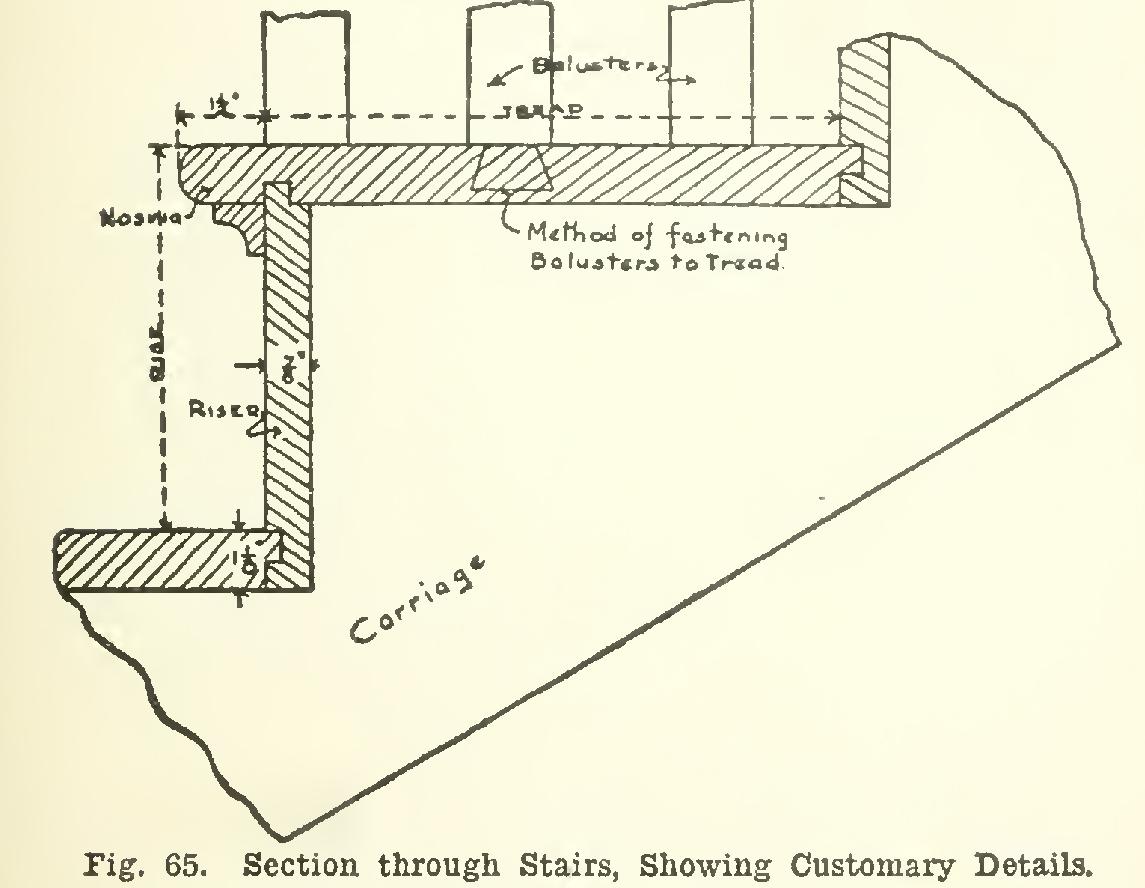

In Fig. 65 are shown the customary details. The riser is known as the vertical portion, and the tread as the horizontal portion. The main supports are usually 2 by 10-inch or 2 by notched to fit the treads and risers, and are called carriages. The balusters are the upright spindles or ornamental pieces supporting the hand-rail.

Various heights of riser to tread have been tried, but the one found most satisfactory is to make the riser from 7 inches to inches. The usual rule for figuring the treads and risers is to make the sum of a tread and riser equal to 17 inches or inches. From this we see that the higher the riser, the narrower will be the tread. If we make the riser inches, then the tread should not exceed 10 inches. The width of tread is exclusive of the nosing, which is usually inches.

Stone stairs, or stairs without a nosing, will have to be wider.

For figuring the number of risers, divide the height from floor line to floor line (in inches), by the height of one riser; the result will be the number of risers.

Fig. 60 shows a stairway with a landing. Fig. 61 is another form of stair with a landing. Fig. 62 is a combination front and back stairs. There are separate stairs up to the land ing; then the back stair joins the main stair. Fig. 62 is the first-floor plan, and Fig. 63 the second-floor plan, of the same stairs.

Where possible, put a coat closet under the stairs. This space cannot be utilized for any thing but a basement stair or a closet. Usually there is a basement stair in the rear of the house.

Fig. 64 shows an elevation of the stairway, giving all necessary information.

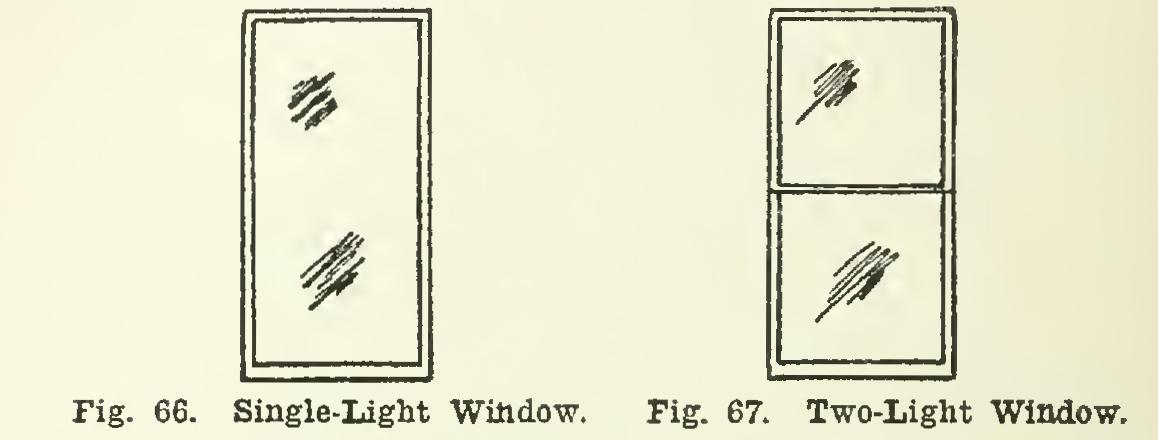

Windows. There are various types of win dows used in the construction of buildings. The plainest is the single-light window shown in Fig. 66. This is either pivoted, hinged, or fixed to slide.

The windows are usually designated accord ing to the number of panes of glass they contain, Fig. 67, for example, being a two-light window. Very often a large glass space is divided into smaller areas by means of horizontal and verti cal strips called muntins, as shown in Fig. 68. The lower sash slides up, while the upper one is usually fixed in place; this upper sash is called a transom.