Details of Construction

sash, window, fig, usually and frame

When windows are grouped in twos or threes, they are separated by means of vertical divisions. These divisions are called mullions. The weights of the sash usually travel in these (see Fig. 69).

The sash is usually the movable frame that contains the glass. A double-hung window is one in which the sash are counterbalanced by iron weights so that the sash will slide easily up and down in grooves in the frame. The sash of a window may be hinged to open like doors, in which case the window is called a casement window. If the sash are hung on pivots, either vertically or horizontally, we speak of the win dow as a pivoted window.

Referring to Fig. 68, A is the lower rail of the sash, usually from 21/2 to 3 inches wide; B is the meeting rail, from 1 to 2 inches wide; C is the stile, usually 2 inches wide; D is the upper rail, of the same width as the stile; E indicates the muntins, which divide the sash into small areas; F is the transom bar, or the fixed bar between the transom G and the double hung sash below.

The usual thicknesses of sash are inches for small windows, to 1%, and sometimes inches, depending upon the size of sash. The larger the window, the heavier the sash must necessarily be.

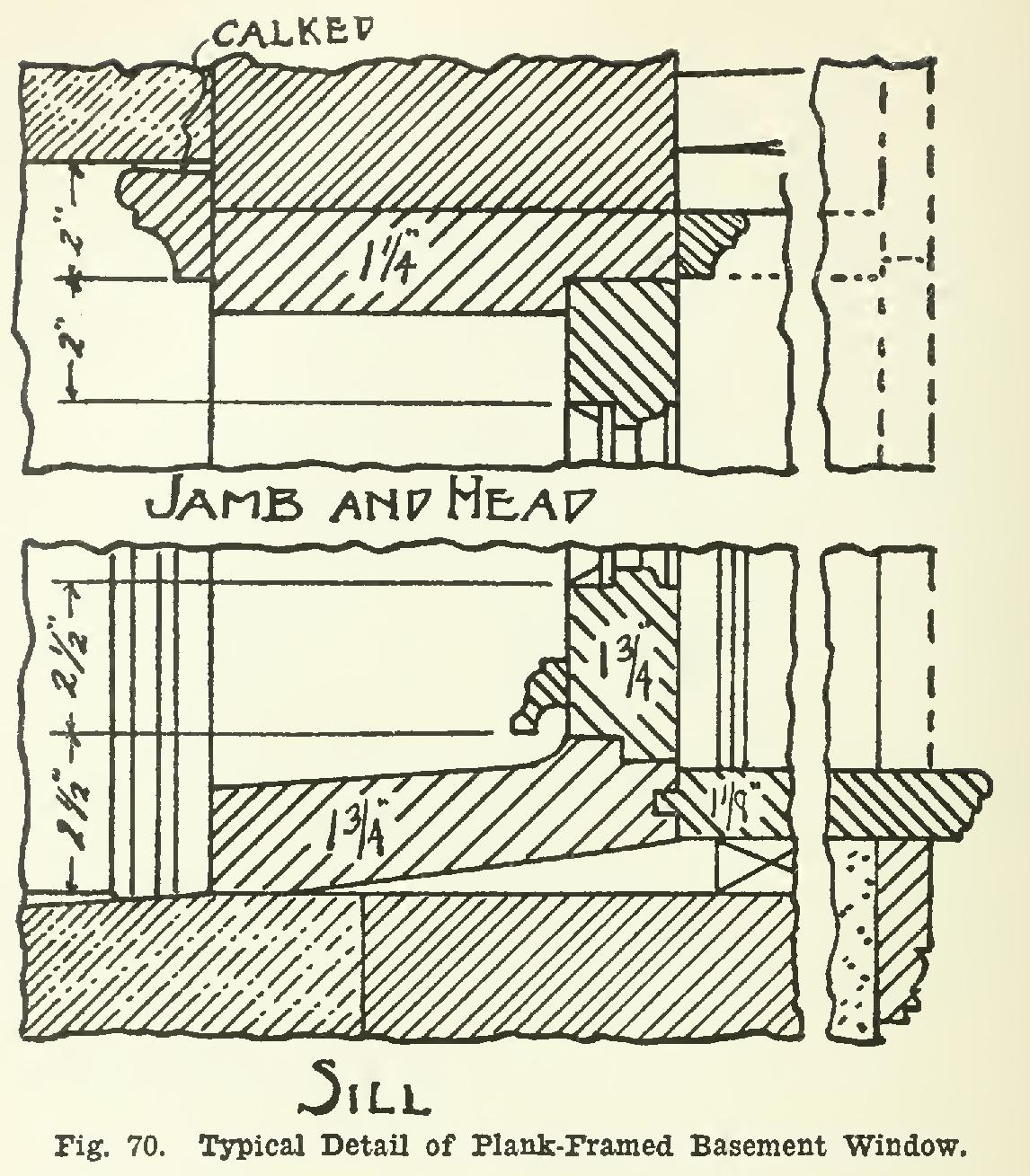

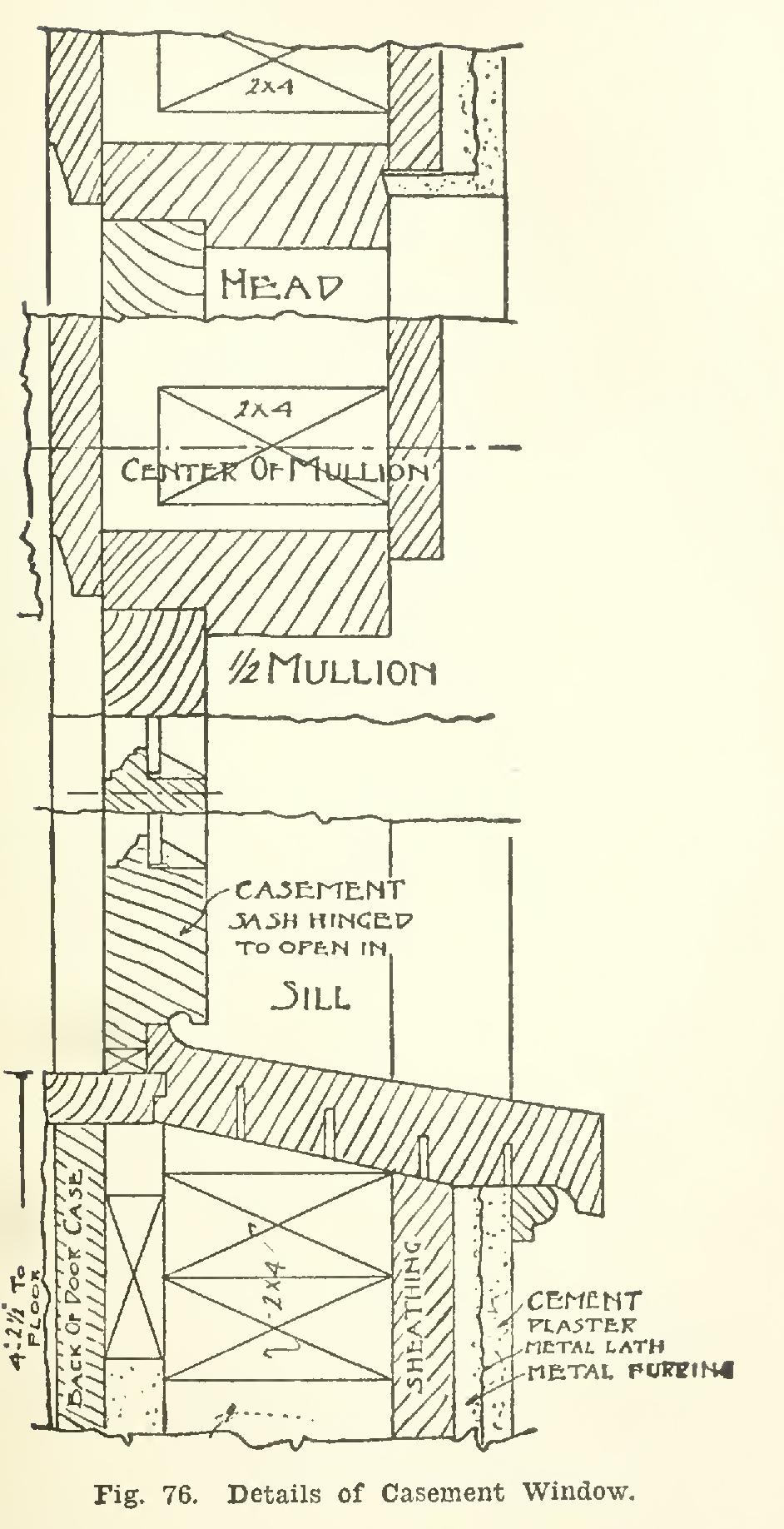

In Fig. 70 we have a plank-framed window. This is the same kind of frame required for the casement window as shown in Fig. 76. Fig. 70 is the typical detail for cellar window construc tion. The windows usually have a single sash which may be divided by muntins into smaller lights. Notice the projection on the bottom rail, which serves as a drip for all water coming from the glass. Such windows are usually hung at the side or top. Fig. 70 is detailed for a brick wall, although the same detail will apply to a frame wall.

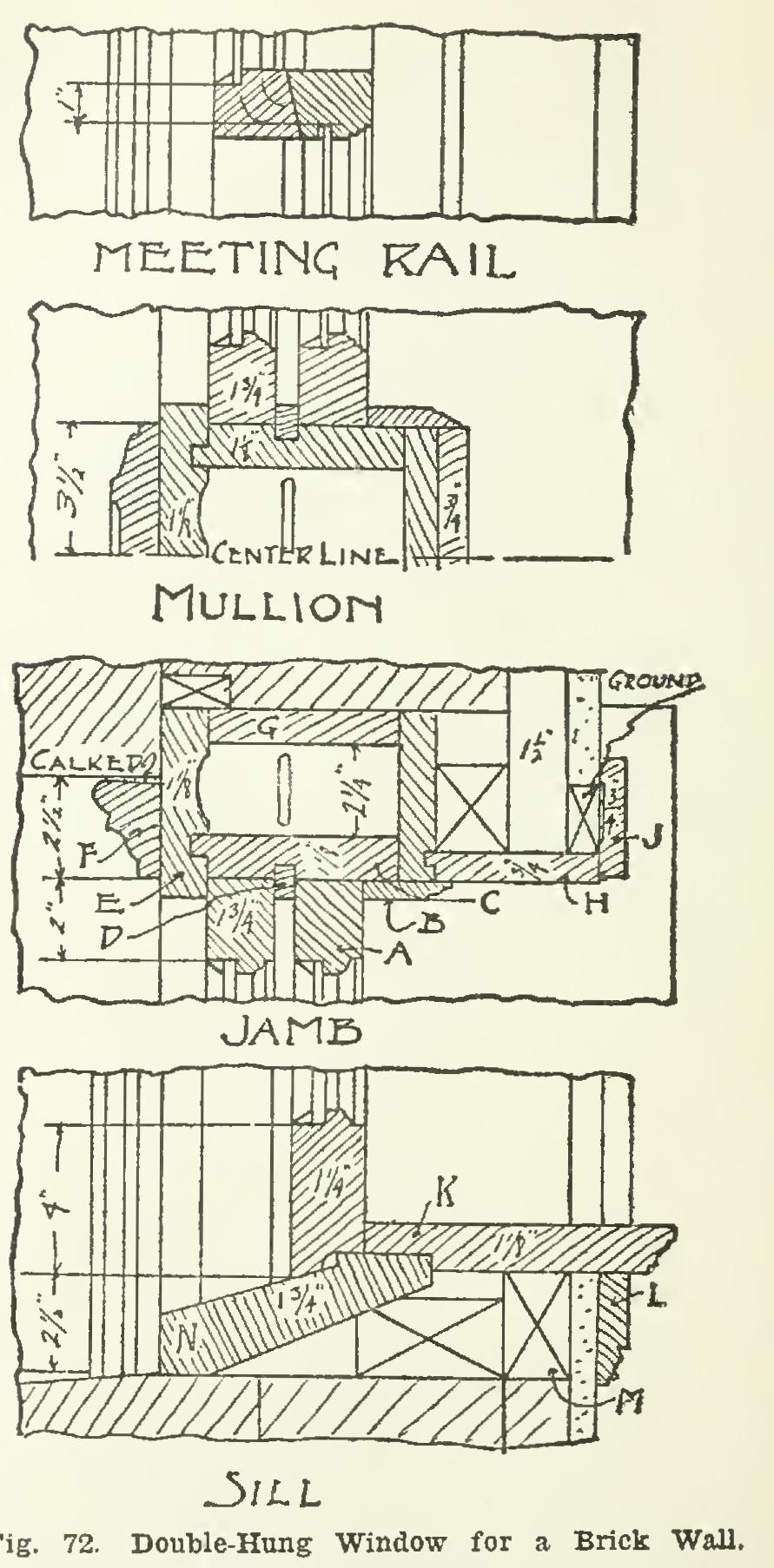

In Fig. 71 we have the details and dimen sions for a double-hung window in a frame wall, the exterior of the wall being plastered. In Fig. 72 we have the details for a double-hung win dow in a brick wall. Notice that there is very little difference in construction. The parts of the construction are named for the sake of clearness, A being the sash, B the inside stop, C the pulley stile, D the parting strip, E the outside casing, F the brick mould or staff-head, G the back lining, H the sub-jamb, J the inside casing, K the stool, L the apron, M the ground, and N the sill.

In Fig. 73 we have the construction for a bay window, showing the boxes, sash, etc.

Fig. 74 shows the details for a dormer or roof window.

Fig. 75 shows the construction for a pro jecting bay window, the sash being hung to swing out. We have shown a half exterior view, a half interior view, and a section.

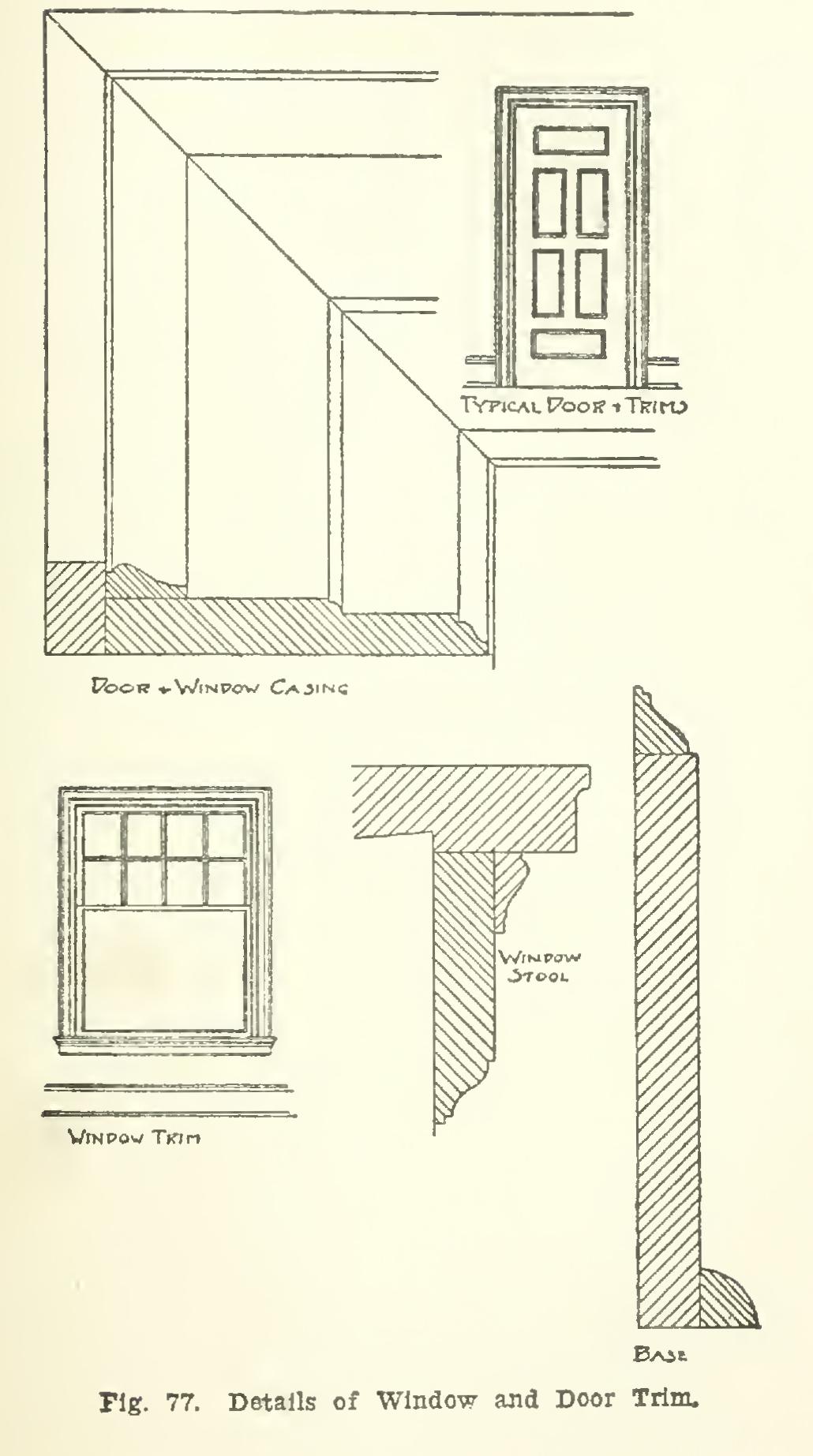

Fig. 76 shows the details of a casement win dow in which the head, mullion, and sill, with all adjoining construction, are shown. Notice the grounds or guide for the plaster work, as spoken of under "Lath and Plaster." Fig. 77 shows the interior elevation of the door and window trim, with a large-scale draw ing of the exact profiles of this trim. The trim, and in fact all interior woodwork, are fastened to the grounds, which are set to serve as guides for the plasterer, and which should be placed back of all interior finish. The base shown is the finish at the floor-line. The base is nailed to grounds; and the quarter-round mould at the floor is nailed to the floor, to cover the crack at the joining of the base and floor-line.