Details of Construction

gutter, floor, fig, building, shown and joists

DETAILS OF CONSTRUCTION It is essential to know the usual method of detailing different portions of the building. For the clear understanding of some of the impor tant parts of a building, there have been pre pared some typical details. The reader, having become familiar with the details shown, can adapt them to any sort of building.

Cornice.

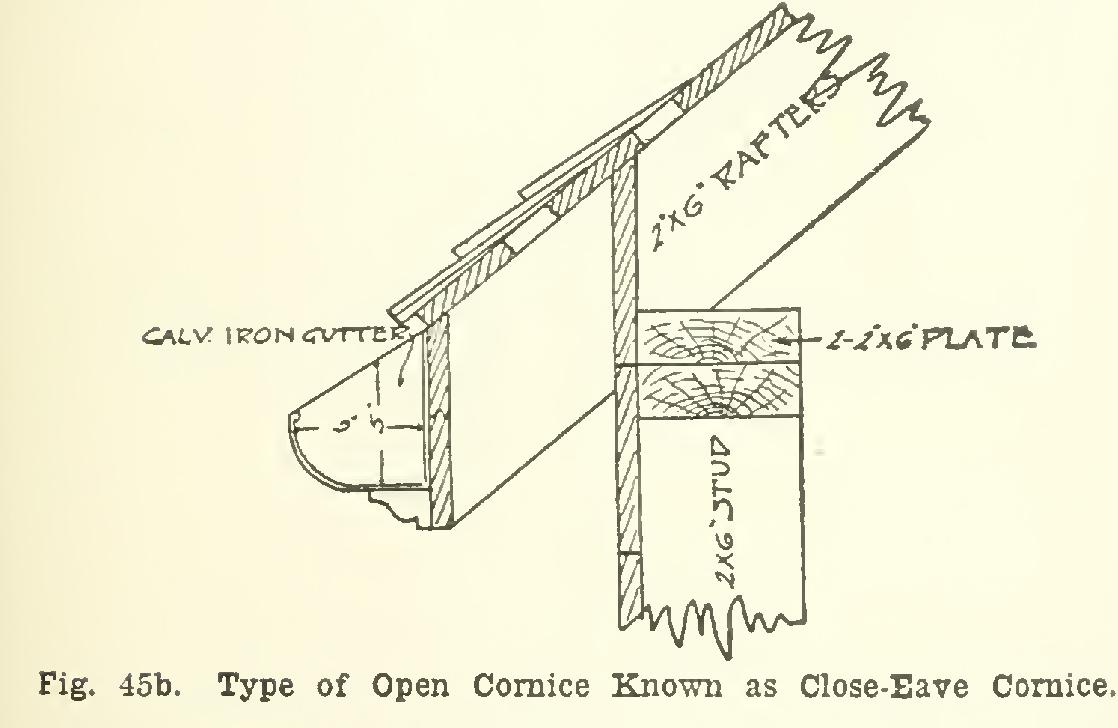

The cornice is the projection at the top of the building, made more or less elaborate. There are several kinds of cornices—the box cornice, as shown in Fig. 44, and the open cor nice, as shown in Fig. 45 (a and b). Referring to Fig. 44, there is the crown-mould A, the fascia B; the planceer or soffit C; the lookout D; the brackets E; the dentil course F. Not all cornices have all these parts. The plainer ones may be without the brackets E and the dentils F; or more elaborate cornices may have more mem bers. The closed cornice always has the gutter built into the upper members; the open cornice has a hanging gutter, as shown in Fig. 45 (a or b).

The gutter, in the best work, is made of cop per; in ordinary work, of galvanized iron; and in the cheapest class of work, tin is used. The durability of these materials is in the order named, the copper wearing usually the life of the building. Galvanized and tin gutters have to be kept well painted; but even with good care, the life of these two materials is limited.

One important feature of a good gutter is to have the metal run well up under the roofing material, and out over the crown-mould. This keeps any water from overflowing up under the roof if the gutter becomes choked with ice or leaves. The gutter should be well pitched or graded to the outlets. The gutter outlets are in turn connected to leaders or down-spouts. These down-spouts are made, usually, of the same material as the gutter. The shape of the down-spouts may be either round or rectangu lar; a very common form is made of corrugated iron, either round or rectangular. The gutter, especially if a hanging gutter, must be securely fastened to the roof at intervals of two or three feet, by means of some sort of hanger. The

down-spouts must be securely fastened to the wall by some approved method.

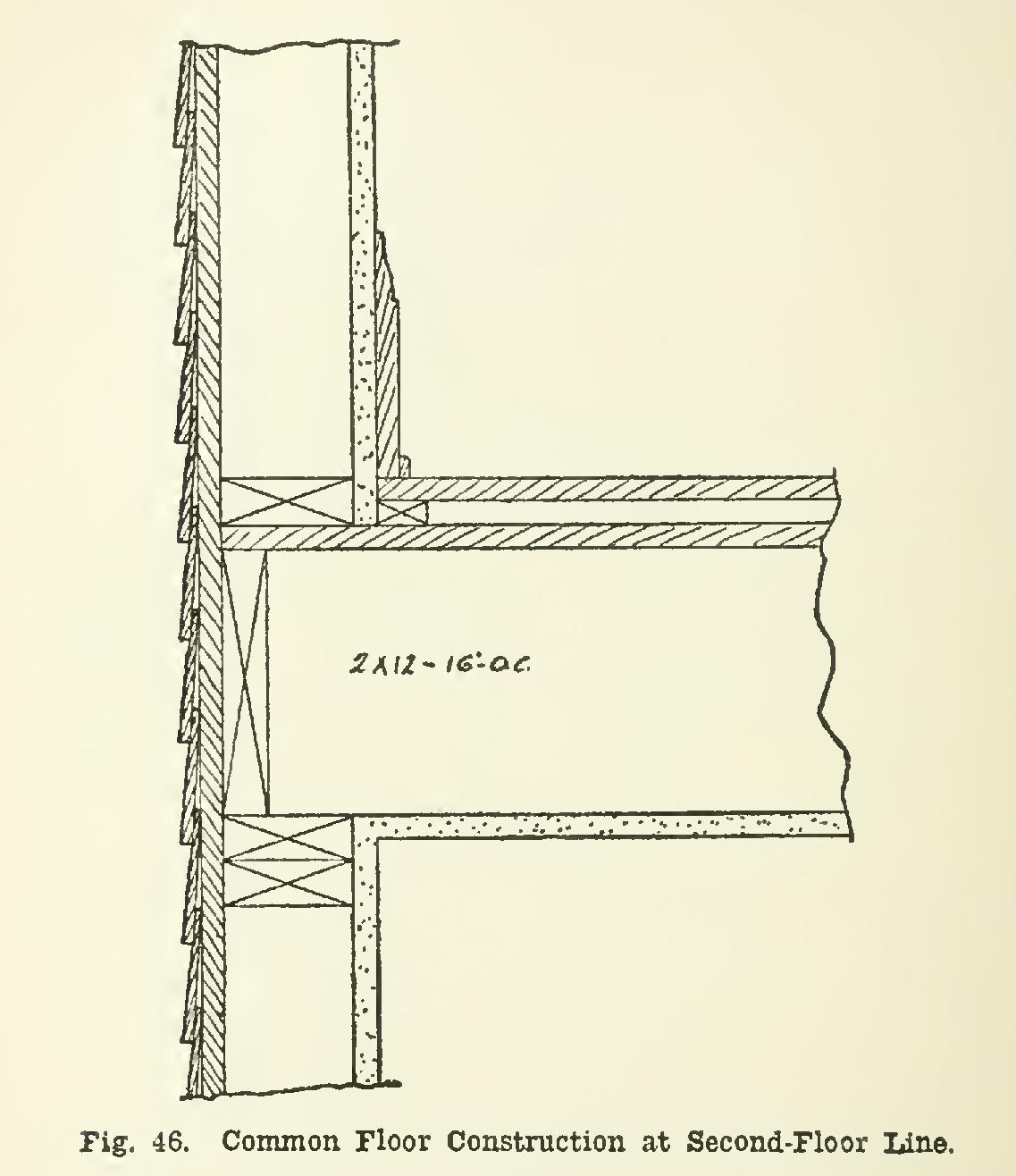

Floor Construction. The floor construction does not vary much (see Fig. 46). In this figure we have the usual construction and method of support at the second or upper floor line. The joists must be of ample size, not only to carry the load safely, but to be stiff enough not to sag or vibrate under a load, since this would crack the plastering or the ceiling below. On the joists is laid an under-floor, usually of boards inch thick, laid diagonally at 45 degrees with the joists, and spiked with two nails on every joist. The flooring laid in this manner braces the building, and resists any tendency to twist.

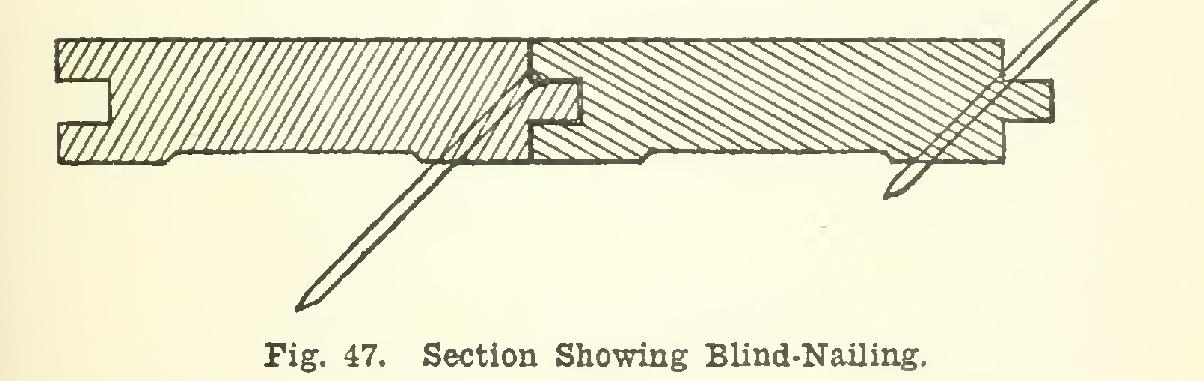

In the best construction, we use some sort of deafening material between the upper and under floor, to deaden sound. The upper floor is of maple, oak, or yellow pine of matched or tongued-and-grooved boards, with the boards parallel to one side of the room. This floor is blind-nailed; that is, the nails are driven in at the intersection of the tongue and the vertical edge, as shown in Fig. 47. This keeps all nail heads hidden from view. The upper floor should be thoroughly kiln-dried----that is, dried arti ficially to drive out the greater part of the moisture, so that when it is finally laid, it will not dry out in the building and open up ugly cracks. For this reason the finished floor should not be laid until the plastering is thoroughly dry. The under side of the joists is lathed and plastered.

Around openings, chimneys, or stair-wells, the joists are supported at the ends by means of a header, or a joist running at right angles to them, to which they are securely spiked; or they may rest on top of a ribbon or board let into the studding, the con struction being similar to the support for the ceiling joists as shown in Fig. 44.