Structural Drafting 148

fig, angles, rivets, riveted, columns and shown

STRUCTURAL DRAFTING 148. By structural drafting is meant the drafting of the iron and steel framework which enters so largely into the construction of the steel bridge and the modern office or commer cial building.

It is impracticable within the limits of the present work to enter into any extended dis cussion of the theoretical and practical ques tions which arise in connection with this subject; and it is therefore the intention to present only the elementary principles and fundamentals, with examples from actual prac tice. Equipped with this understanding of the essentials, the draftsman should be able to readily fall into line with the practice in any particular drafting room.

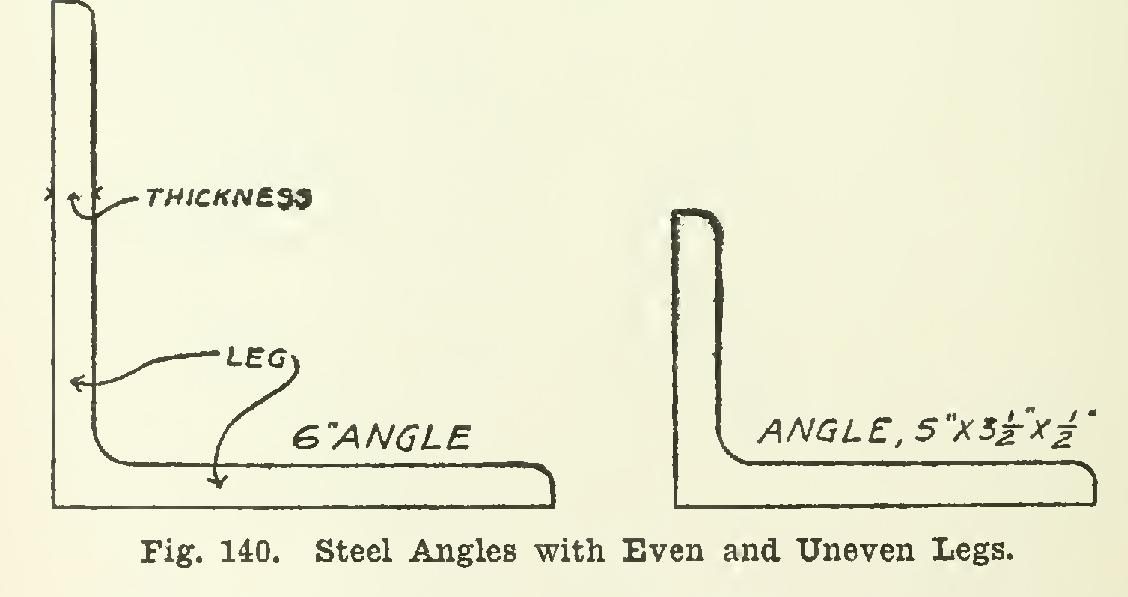

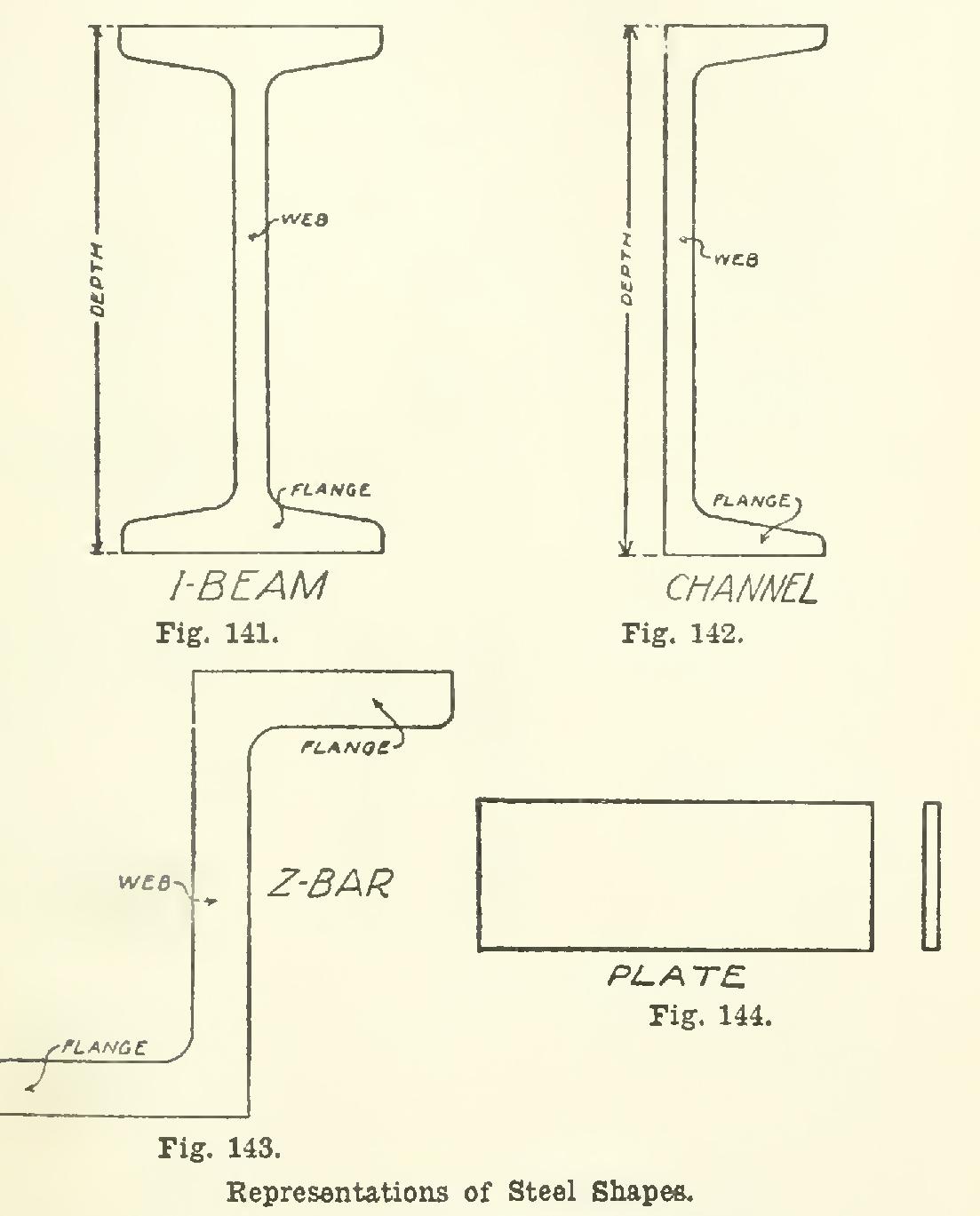

The various pieces which are used in steel building construction are largely of certain standard shapes and sizes which are rolled iu the mills. Types of the usual elementary forms are shown in Figs. 140 to 144. These views show the pieces endwise, thus representing the actual shape. The angles, Fig. 140, with even and un even legs, are made in various standard sizes, and are listed in the handbooks issued by the various steel companies.

Solid and Members. The beams, girders, and columns may be of one piece, or composed of some of the elementary parts riveted together. Thus a beam or girder may be of the I-beam style, Fig. 141, in one solid piece; or it may be formed as in Fig. 146, of a plate and four angles riveted together.

Angles (Fig. 140), channels (Fig. 142), (Fig. 143), and plates (Fig. 144), are the elementary parts most used in the construc tion of built-up girders and columns. The I-beam is commonly used as a beam or girder, while the uprights or columns are usually of the built-up variety.

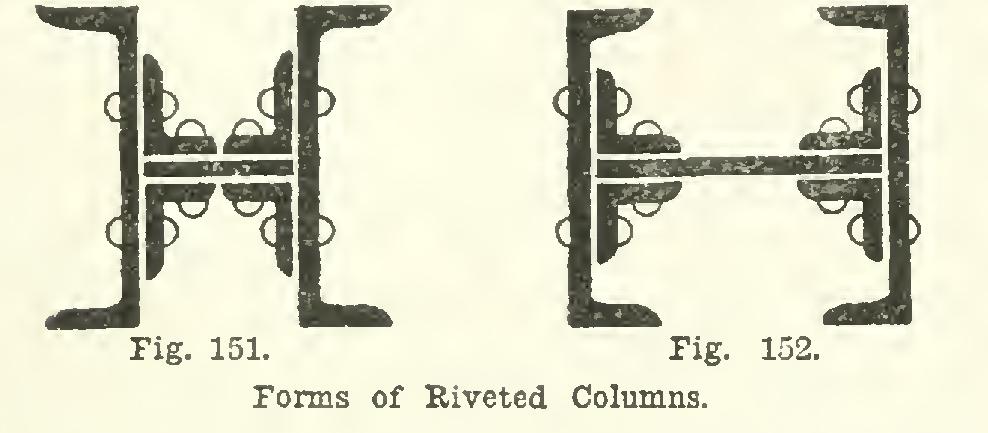

Figs. 145 to 152 show in section some of the common forms of riveted columns. These columns, as shown in the figures, are variously made up of angles, plates, channels, Z-bars, and lacing or lattice-work. The light lines of Figs. 145 and 148 indicate lattice-work or lacing (see Figs. 153 and 154); and the heavy lines of the other figures are plates. Fig. 145, for example, is the section of a coltunn composed of four angles latticed together. Fig. 147 represents

a column formed of four angles riveted to a middle plate and reinforced by two other plates at the top and the bottom. In these figures, the narrow spaces left between the members which are riveted together are for the sake of showing the arrangement more clearly, and of course do not mean that such spaces exist on the actual column.

Rivets and Bolts. In fastening the various steel shapes together, rivets or bolts are used. When bolts are employed, they are generally square-headed, with V threads, and are repre sented in the customary manner (see "Dimen sioning of Bolts," under Article 140).

Rivets are very largely used for fastening together the different members of a built-up beam or column, and for making connections with other beams. The hole for the rivet is made from inch to inch larger than the rivet. Rivets are driven hot, the metal being forced to fill the slightly larger hole. Riveting is done in two ways, by hand and by machine.

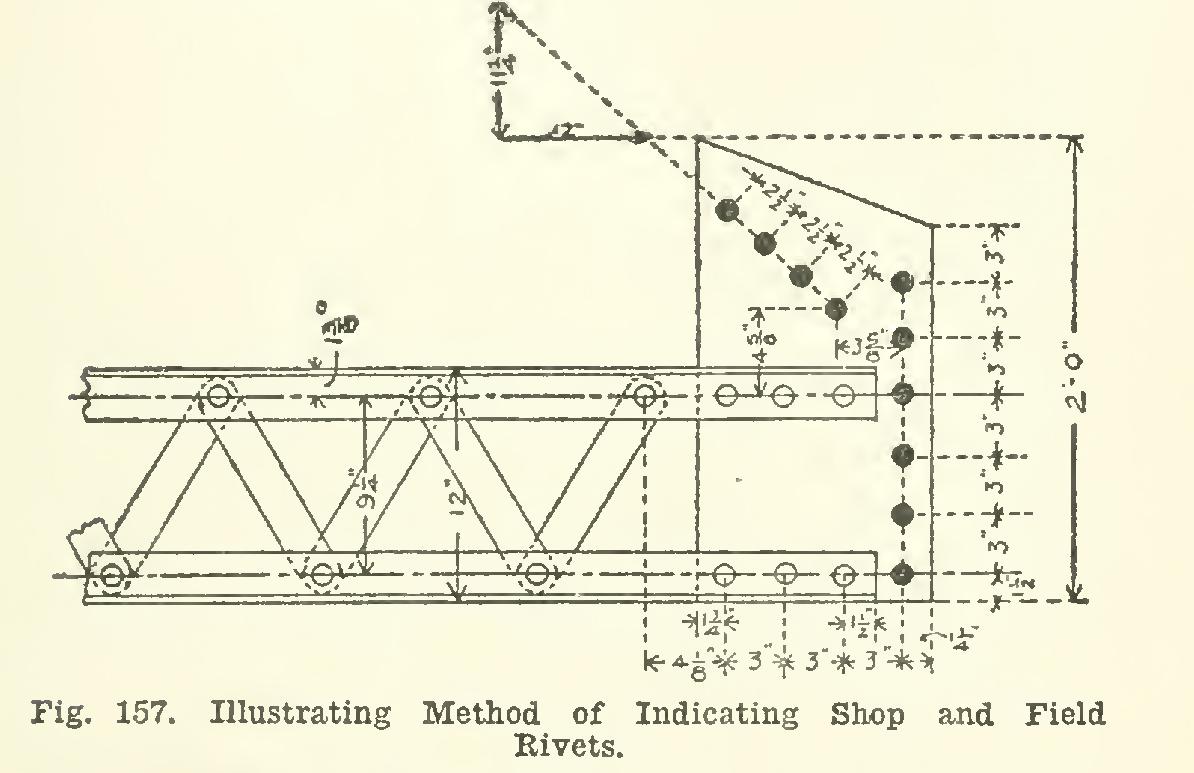

Fig. 155 shows a machine-driven rivet; and Fig. 156, one driven by hand. As far as practi cable, riveting is done in the shop, and this is known as shop riveting; some riveting, how ever, must necessarily be done at the place of construction, and this is known as field riveting.

On the drawing, the rivets to be shop-driven are shown in position with the heads drawn; while for those to be riveted in the field, only the holes are shown, blacked in. This distinc tion is illustrated hi Fig. 157, which is taken from a working drawing of one end of a bridge strut. This strut is composed of four angles laced together, like the column shown in section in Fig. 145, two angles at the top, and two at the bottom. The blank circles at the ends of the lacing bars, and those at the ends of the angles, are the heads of the shop-driven rivets, while the black holes are for the rivets which are to be driven in the field. These latter rivets are those by which the strut is to be fastened in position.