A Writing Desk

inches, pieces, seven-eighths, piece, lines, inch and six

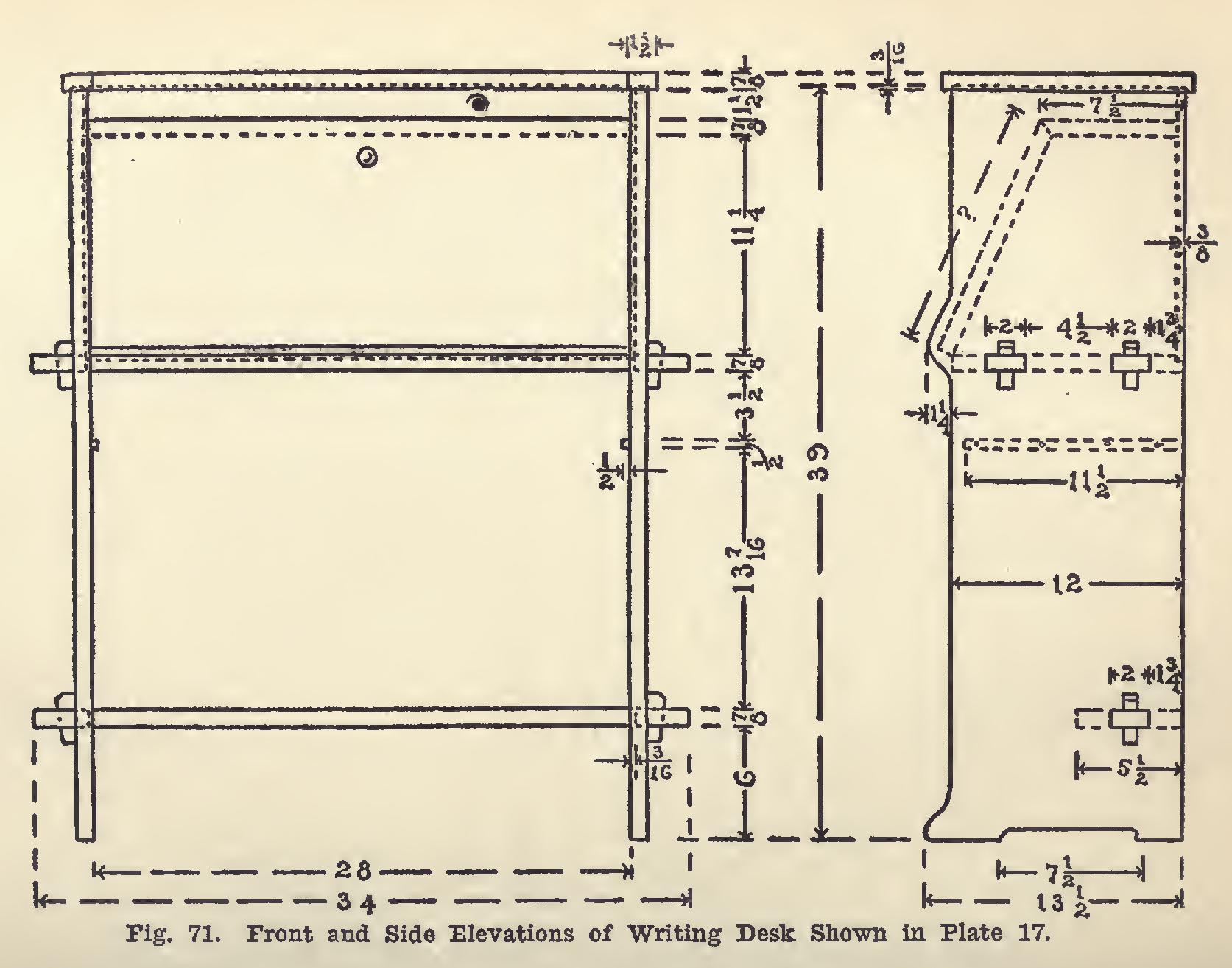

A WRITING DESK The writing desk illustrated in Plate 17 was made by a grammar-grade boy of more than av erage skill.

Only good, clear, well-seasoned lumber should be used. White or red oak in the hard woods or chestnut in the soft woods will finish nicely. Especial care should be taken to select for the wide boards those which have been sawed from such a part of the log as will prevent their warping badly. If you do not know how to tell them, ask some woodworker to explain this fea ture to you.

The rough stock needed to make the frame work is as follows: For the two sides, two seven-eighths-inch, mill-planed boards fourteen inches wide by three feet six inches long; for the lid, one piece seven-eighths of an inch, by four teen inches, by two feet six inches; for the stretcher, one piece seven-eighths of an inch, by six inches, by three feet; for the top, one piece seven-eighths of an inch, by eight inches, by two feet six inches; for the base of the compart ments, one piece of seven-eighths-inch stock twelve and one-half inches wide by three feet long.

In addition to the above, there will be needed, for around the top, two pieces seven-eighths, by one and three-quarters, by eighteen inches; one piece of the same thickness and width, with a length of thirty-two inches. The keys can prob ably be got from the waste of the other pieces, so may the two strips which support the drawer. The stock for the other parts will be listed later.

Surface or smooth with smoothing plane and scraper the broad surfaces of the stock men tioned above.

Begin with the sides of the desk, first getting a joint-edge and squaring the two ends of each so that the length will be thirty-nine inches. Next, with a long straight-edge and a sharp pen cil, mark a line parallel to each joint-edge and twelve inches from it. Do not rip along these lines yet, as the curves are still to be located thereon.

Place these side pieces so that their ends are even, and their joint-edges up; and square knife lines across the edges at the following points: Six inches from the bottom; then, from this point, seven-eighths of an inch, thirteen and seven-sixteenths, one-half, three and one-half, seven-eighths, eleven and one-quarter, and finally seven-eighths of an inch.

Corresponding to the marks made on the joint-edges, carry, with knife and large square, lines across the boards on the inner surfaces. The first and second lines, measuring from the bottom, should be carried across five and one half inches from the joint-edge; the third and fourth, eleven and one-half inches; the fifth and sixth, twelve inches; the eighth, seven and one half inches. The length of the seventh cannot be determined until the location of the lid end is marked. Fig. 71 shows how this can be done. The first pair, third pair, and fourth pair of lines represent edges of gains which are to be chiseled to a depth of three-sixteenths of an inch. Be fore these gains are cut, however, the pieces which are to be housed should be placed on the marks to make sure that the gains are not laid out wider than the entering pieces are thick. If they are slightly narrower, no harm is done, as the ends of the entering pieces may be planed slightly on the under sides. The second pair of lines are not to be chiseled, but denote the loca tion at which the drawer supports are fastened, screws being used.

Having located these gains, the position of the lid end may be marked upon the side pieces with light pencil marks, and then the curve (Fig. 71) is located. The shapes at the bottom may be modified to suit the taste of the individual.

A turning saw will be needed for the curves.

A more economical way of getting out the sides would be to use a twelve-inch board in stead of the fourteen-inch, and glue on pieces to make the required width at the curves. This is more difficult, however, and the saving on one desk so small that the first way is preferable.

Before cutting the gains in these pieces, the mortises should be laid out and cut. For the mortise which is to receive the tenon on the stretchers, gauge from the back edge of the side piece of the desk, which is the joint-edge, first one and three-quarters inches, then three and three-quarters inches. The gauging should not extend beyond the knife marks which locate the gain. As the mortise must be cut from each side, the gauge-marks must be placed on each side.