Door

inches, inch, tenons, pieces, one-half, length and width

For the cross-rails, square up the four sides of three pieces so that each shall have a width of one and one-half inches. The length shall be the same as above.

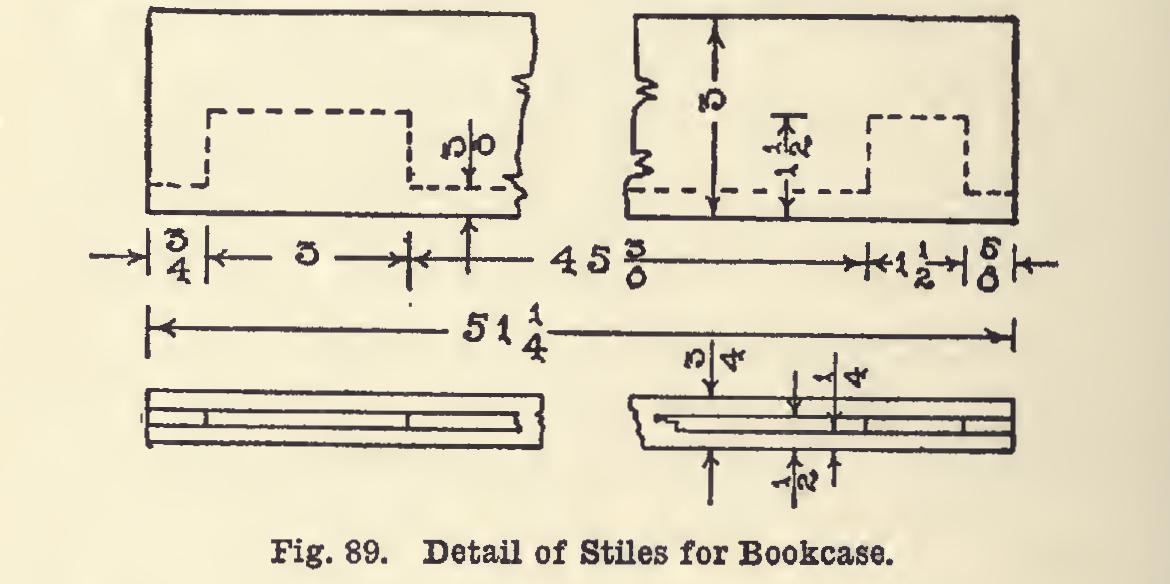

The stiles require two pieces somewhat over fifty inches long, with a width of two and one quarter inches, each jointed on one edge.

There will also be needed two pieces squared to a width of one and one-half inches, with a length of forty-seven and one-half inches.

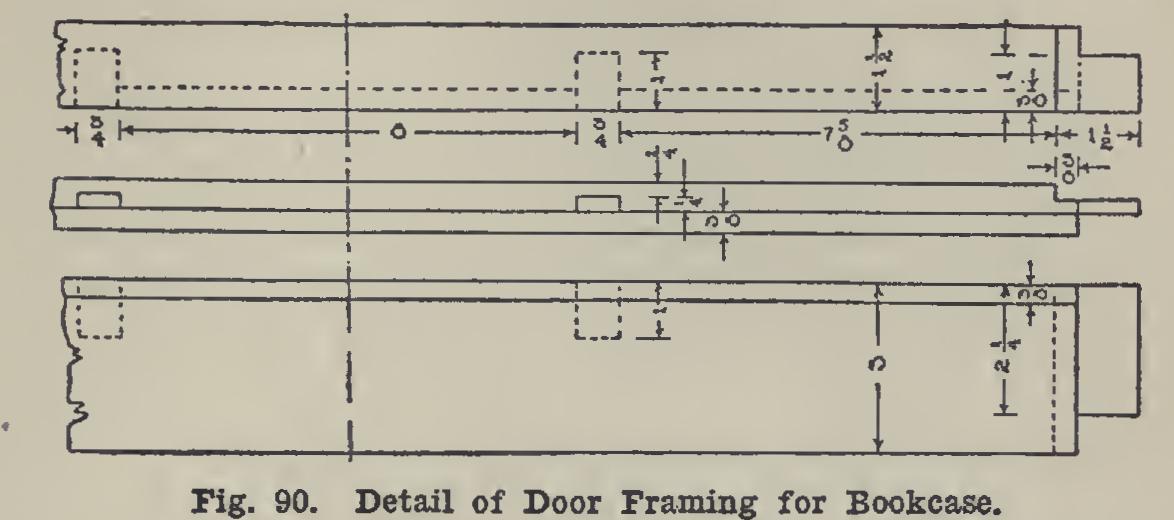

Lay off the top and bottom rails. Place them together in the vise, with their joint-edges up; :Ind the middle of their length; and measure to either side four inches, three-quarters, seven and five-eighths, three-eighths, and from the same point that this last measurement was made from, one and one-half inches (Fig. 90). Knife lines squared across the edges through these points will locate the ends of the mortises and the shoulders of the tenons. Setting the gauge to one-quarter, then to one-half, mark the sides of the mortises and tenons. Gauge from what are to be the outer faces of the pieces.

Fig. 90 shows that the tenons are to have one shoulder three-eighths of an inch longer than the others. This is to permit the filling of the space caused by rabbeting. The tenons on the top rails are one inch wide, on the bottom rail two and one-quarter inches wide, measured or gauged, of course, from the jointed edges.

The mortises are to be cut one inch deep. The easiest way to cut all of these small mor tises is to use a chisel just the width the mortise is to be, and cut with it alone, not boring.

Rabbet the joint-edge, on what is to become the inner surface, to three-eighths by three eighths of an inch. It is taken for granted that a rabbeting plane and plow are available, or possibly a circular saw. To cut all of these rab bets by gauging and chiseling would be very tedious—and unsatisfactory, too.

The length of the cross-rails can be got by placing them alongside the top or bottom rails. The location of the cross-lap joints can be simi larly obtained.

The muntins can be marked by placing them alongside a stile. All the cross-rails and muntins are to be rabbeted on each of their two edges.

The tenons on these pieces are to be one quarter of an inch thick and three-quarters of an inch wide. The manner of gauging them will

be suggested from the experience obtained in laying out previous tenons. The gauge settings are three-eighths and one and one-eighth inches for width, and one-quarter and one-half of an inch for thickness, measured from the outer face. On the cross-rails the tenons are to be one and one-half inches long, as will be indicated when they are held against the top rail. The length of tenon on the muntins is but one inch.

The cross-lap joint occurs at the intersec tion of these pieces, and is made by cutting part out of one piece and part out of the other. This Makes a stronger door than would be obtained by mortising one piece into another. Care must be taken to locate these joints properly. If the pieces are straight, the best way is to place one upon the other in their proper relative position, as indicated by putting the frame together and squaring it.

After scraping and sandpapering the parts, they should be glued and thoroughly clamped, squaring the frame with a steel square, or by measuring the diagonals to see that one equals the other.

The door should be fitted before the back of the case is screwed in place. The door may then be held in place by one person, while another marks its size and shape with a sharp pencil or a knife, upon its back. The ends and edges may be planed to these lines with an assurance that it will fit. In running a pencil along, in mark ing, be careful always to keep the lead against the side of the case, otherwise a correct mark would not result, and the door would be too small. Square up the case and brace it before marking the door.

Since the door is hung flush, butterfly surface hinges and a surface lock may be used. These are so easily applied that no directions are nec essary. Their positions are shown in the photograph, Plate 18.

The glass may be either single or double strength. The sizes are indicated in Fig. 85. These panes should be firmly embedded in putty. A thin layer should be put in the recess, the glass should then be placed, another layer of putty applied, after which a triangular wood fillet is tacked in place.