Testing of Cement

samples, tests, material, gravity, specific, cubic and tion

TESTING OF CEMENT The most accurate and thorough tests of ce ment are those which are made in professional testing laboratories. These, however, are not always available; and fortunately they are not always necessary. In large constructions such as public works, and in smaller structures where very important values are at stake, laboratory tests are invariably insisted on. In all ordinary work, however, simpler tests, calling for no very elaborate apparatus and requiring no great de gree of technical training, will be quite suffi cient for practical purposes.

In careful technical supervision of processes of manufacture, and consequently in uniformity and reliability of product, the standard Ameri can brands of cement have no equals anywhere. There is, however, a possibility that now and then some small part at least of the output of the cement plant may fall below the regular standard in quality; and for that reason, on all important work, samples should be taken from every shipment—in fact, a sample from every barrel—and these samples should be tested with sufficient care at least to determine the presence or absence of any radical defects which would render the material unfit for use.

The methods of testing briefly described be low, are in substance those recommended by the Committee on Uniform Tests of Cement, of the American Society of Civil Engineers.

Samples for Testing.

Enough samples should be taken to insure an average representation of the shipment. No rule can be laid down as to how many; that will depend on the size and im portance of the work.

The samples should be freed from lumps and foreign material by being passed through a sieve having 20 meshes per linear inch. This is also an effective method of mixing several samples from the same shipment to obtain an average. Where time will permit, however, the samples should be tested separately, as in this way uni formity, or the lack of it, will be most accurately shown. Samples removed from barrels or bags should extend from the surface well toward the center of the package.

Chemical Analysis.

A chemical analysis should show the presence of adulterants, such as slag, stone dust, or other inert materials, if these happen to be present in any considerable quantity. It may also show the presence of certain active constituents, such as magnesia and sulphuric anhydride, in harmful excess, though opinions differ as to the proportions of these which are admissible. Up to 5 per cent of mag nesia and 1.75 per cent of anhydrous sulphuric acid will probably do no harm.

A determination of the principal constituents of cement—lime, silica, alumina, iron oxide— should not be insisted on as a conclusive indica tion of quality, for these may safely vary within comparatively wide limits. Imperfect prepara tion of the raw material (such as insufficient fineness of grinding), or defective burning, is most frequently the cause of the trouble. Ce ment made from very finely ground material, and thoroughly burned, may contain much more lime than the amount usually present, and still be perfectly sound. On the other hand, cements low in lime may, on account of careless prepara tion of the raw material, be of dangerous char acter. Further, the ash of the fuel used in burn ing may so greatly modify the composition of the product as largely to destroy the significance of the results of analysis. All chemical analyses, therefore, should be supplemented by physical tests.

Specific Gravity.

The specific gravity of cement is lowered by adulteration and hydra tion, but the adulteration must be in considerable quantity to affect the results appreciably. Dif ferences in the specific gravity of cement are usually very slight, so that great care must be taken in making the tests.

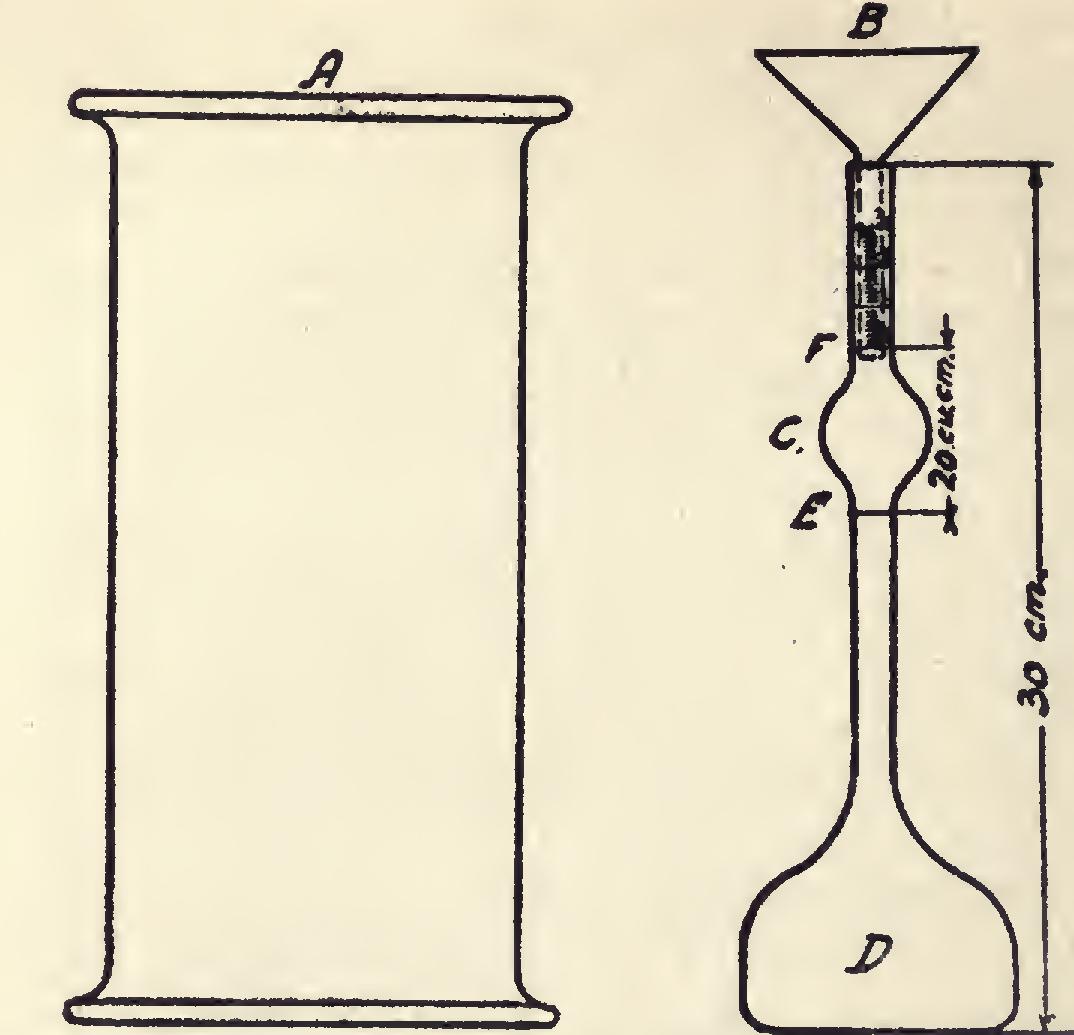

The most convenient apparatus for deter mining specific gravity is that devised by Le Chatelier, a French engineer, and illustrated in Fig. 2. It consists of a flask D, of 120 cubic centimeters (7.32 cubic inches) capacity, the neck of which is about 20 centimeters (7.87 inches) long. In the middle of this neck is a bulb C, above and below which are two marks F and E, the volume between which is 20 cubic centimeters (1.22 cubic inches). The neck has Fig. 2. Le Chatelier's Apparatus for Determining Specific Gravity of Cement.