Testing of Cement

mixing, material, water, test, pieces, briquettes, time and quantity

Care should be taken to keep the needles clean, as the collection of cement on the sides of the needle retards the penetration, while cement on the point reduces the area and tends to in crease the penetration.

The determination of the time of setting is only approximate, being materially affected by the temperature of the mixing water, the tem perature and humidity of the air during the test, the percentage of water used, and the amount of moulding the paste receives.

Sand for Testing.

The sand recommended as standard for testing purposes, should pass a 20-mesh sieve, and leave not over 1 per cent on a 30-mesh sieve after one minute of continuous sifting. These requirements are met by the natural sand from Ottawa, Ill., as before ex plained.

Briquettes for Testing.

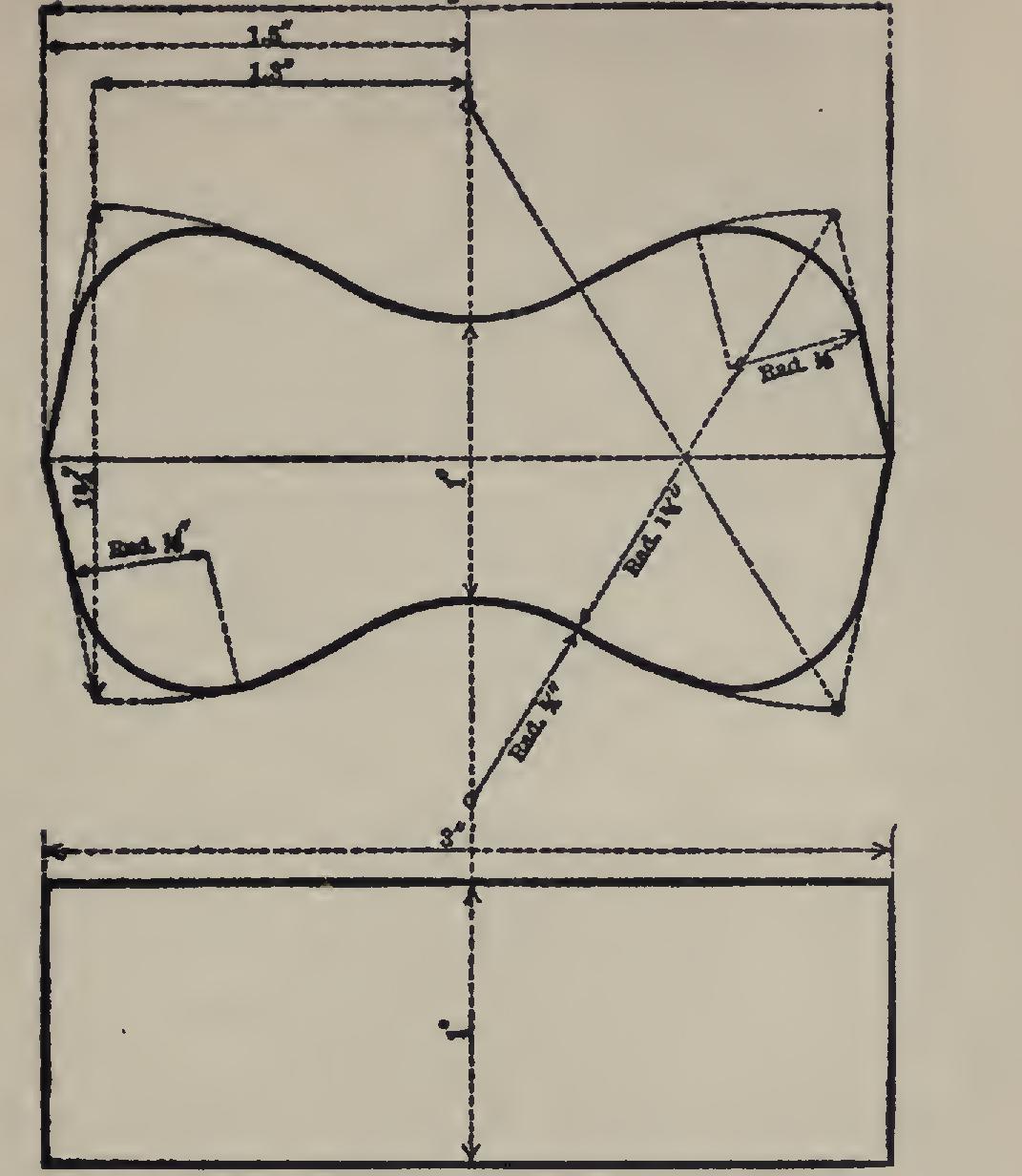

The form and dimensions of briquettes for testing are indi cated in Fig. 4. The moulds for the briquettes should be strongly made of brass, bronze, or other material equally resistant to corrosion, and should be wiped with an oily rag before using. Gang moulds, permitting several briquettes to be made at one time, are pref erable to single moulds, as the greater quantity of mortar that can be mixed tends to give greater uniformity in the results.

Mixing for Tests. All proportions should be stated by weight; the quantity of water to be used should be stated as a percentage of the dry material.

The metric system is recommended because of the convenient relation of the gram and the Fig. 4. Details of Cement Briquette for Testing.

cubic centimeter, one gram (the metric unit of weight) being approximately equal to the weight of 1 cubic centimeter of pure water at its maximum density.

The temperature of the room and the mix ing water should be as near 21 degrees C. (70 degrees F.) as it is practicable to maintain it.

The sand and cement should be thoroughly mixed dry. The mixing should be done on some non-absorbing surface, preferably plate glass. If the mixing must be done on an absorbing surface, it should be thoroughly dampened prior to use.

The quantity of material to be mixed at one time depends on the number of test pieces to be made; about 1,000 grams (35.28 oz.) makes a convenient quantity to mix, especially by hand methods.

The Committee, after investigation of the various mechanical mixing machines, has de cided not to recommend any machine that has thus far been devised, for the following reasons: (a) The tendency of most cement is to "ball up" in the machine, thereby preventing the working of it into a homogeneous paste.

(b) There are no means of ascertaining when the mixing is complete, without stopping the machine.

(c) It is hard to keep the machine clean.

The material is weighed, and placed on the mixing table. A crater is formed in the cen ter, into which the proper percentage of clean water is poured; the material on the outer edge is turned into the crater by the aid of a trowel. As soon as the water has been absorbed, which should not require more than one minute, the operation is completed by vigorously kneading with the hands for an additional minutes, the process being similar to that used in knead ing dough. A sand-glass affords a convenient guide for the time of kneading. During the operation of mixing, the hands should be pro tected by gloves, preferably of rubber.

Moulding. Having worked the paste or mortar to the proper consistency, it is at once placed in the moulds by hand. The material should be pressed in firmly with the fingers, and smoothed off with a trowel, without ramming. The material should be heaped up on the upper surface of the mould; and, in smoothing off, the trowel should be drawn over the mould in such a manner as to exert a moderate pressure on the excess material. The mould should then be turned over, and the operation repeated.

A check upon the uniformity of the mixing and moulding is afforded by weighing the briquettes just prior to immersion, or upon removal from the moist closet. Briquettes which vary in weight more than 3 per cent from the average, should not be tested.