Testing of Cement

water, grams, quantity, sieve, degrees, cm and weight

a diameter of about 9 millimeters (0.35 inch), and is graduated into tenths of cubic centimeters above the mark F. Benzine (62 degrees &tune naphtha), or kerosene free from water, should be used in making the test.

There are two methods of procedure: (1) The flask is filled with either liquid to the lower mark E. Take 64 grams (2.25 oz.) of the cement to be tested, previously dried at 100 degrees C. (212 degrees F.), and cooled to the temperature of the liquid; and gradually pour it into the flask through the funnel B (the stem of which reaches down to top of bulb 0) until the upper mark F is reached. The difference in weight between the cement remaining and the original quantity (64 grams), is the weight which has displaced 20 cubic centimeters.

(2) Or the whole quantity of the powder may be intro duced, causing the level of the liquid to rise to some division of the graduated neck. This reading, plus 20 cu. cm., is the volume displaced by 64 grams of the cement.

Water might just as well be used as benzine or kerosene, were it not for its chemical activity in connection with cement. If water were used, the cement would undergo radical changes and would not displace an equivalent volume of water.

The specific gravity is then obtained by divid ing the weight of cement (in grams) by the dis placed volume (in cubic centimeters), for the weight of a gram is approximately the same as that of a cubic centimeter of water.

During the operation, the flask is kept im mersed in water in the jar A, to preserve a uniform temperature in the liquid.

The determination should be made on the cement as received; and should it fall below 3.10, a second determination should be made on the sample ignited (that is, exposed to a blast flame for, say, 15 minutes) at a low, red heat. The results of tests of specific gravity may help to detect adulteration. In themselves, how ever, they are not necessarily conclusive as an indication of the quality of a cement, but, in combination with the results of other tests, may afford valuable indications.

Fineness. It is generally accepted that the coarser particles in cement are practically inert, and it is only the extremely fine powder that possesses adhesive or cementing qualities. The more finely cement is pulverized, all other con ditions being the same, the more sand it will carry and still produce a mortar of a given strength.

The degree of pulverization is ascertained by measuring the residue retained on certain sieves. Those known as the "No. 100" and "No. 200" sieves are recommended for this purpose. The sieves should be made of brass wire cloth; and should be circular, about 20 cm. (7.87 in.) in diameter, 6 cm. (2.36 in.) high, and provided with a pan 5 cm. (1.97) in. deep, and a cover. The wire cloth in the No. 100 sieve contains 96 to 100 meshes to the linear inch; in the No. 200 sieve, 188 to 200 meshes, giving respectively about 10,000 and about 40,000 meshes to the square inch. A quantity weighing 50 grams (1.76 oz.) or 100 grams (3.52 oz.), dried at 100 degrees C. (21 degrees F.) should be used for the test.

As mechanical sieving is not so practicable or efficient as hand sieving, the following is the method of procedure: The thoroughly dried and coarsely screened ;ample is weighed, and placed on the No. 200 sieve, which, with pan and cover attached, is held in one hand in a slightly inclined position, and moved forward and backward, the side being at the same time struck gently the palm of the other hand, at the rate of about 200 strokes per minute. The operation is continued until not more than one-tenth of 1 per cent passes through after one minute of continuous sieving. The residue is weighed, then placed on the No. 100 sieve, and the operation repeated. The work may be expedited by placing in the sieve a small quantity of steel shot. The results should be reported to the nearest tenth of 1 per cent.

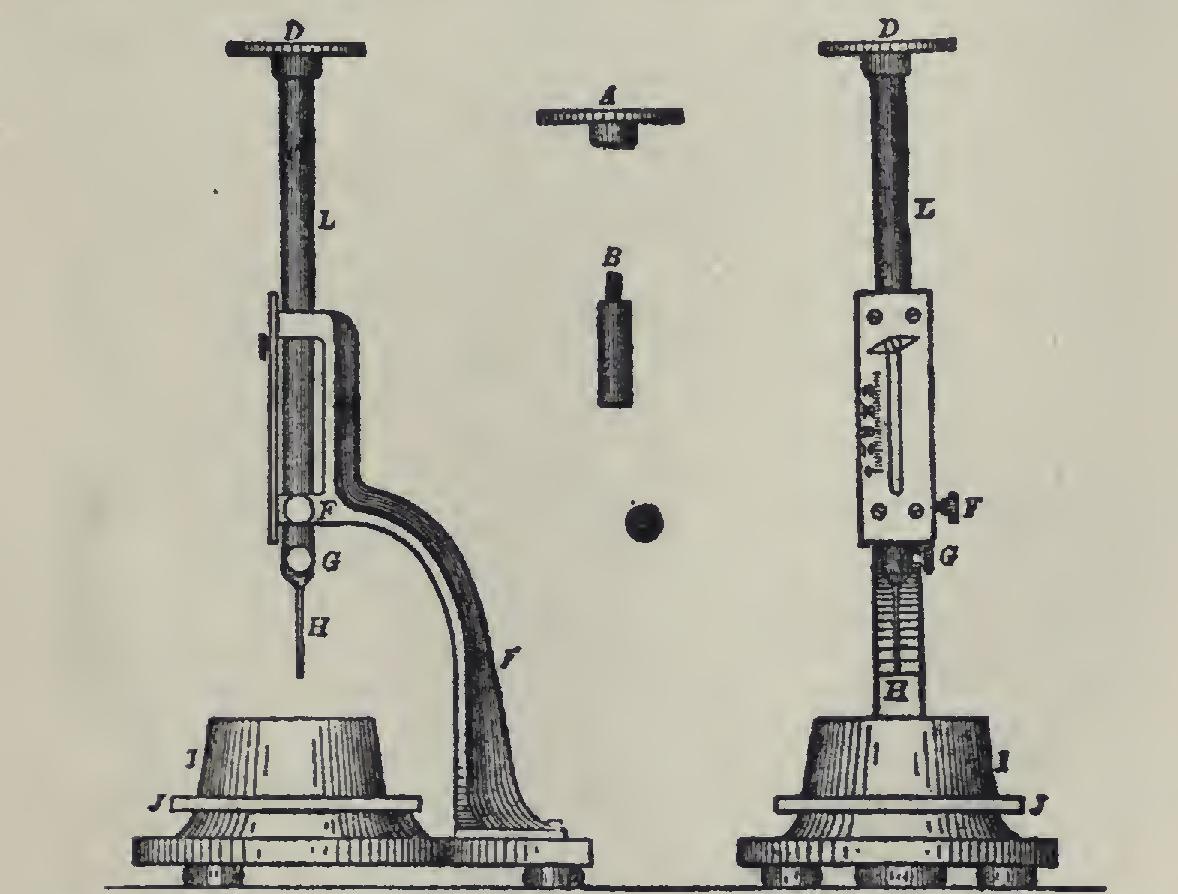

Normal Consistency. The use of a proper percentage of water in mixing the pastes (mix Fig. 3. Front and Side Views of Vicat Needle Apparatus for Test ing Cement.

tures of cement and water) on which tests are made for time of setting, soundness, strength, etc., is of great importance, as it affects vitally the results obtained. The quantity of water should be just sufficient to reduce the cement to a certain state of plasticity, known as normal consistency. Various methods have been pro posed for making this determination, none of which has been found entirely satisfactory. The Committee recommends the use of the Vicat needle apparatus for this purpose.