Testing of Cement

tests, test, air, water, degrees, strength, moist and hours

A moist closet consists of a soapstone or slate box, or a metal-lined wooden box, the metal lining being covered with felt, and this felt kept wet. The bottom of the box is so constructed as to hold water, and the sides are provided with cleats for holding glass shelves on which to place the briquettes. Care should be taken to keep the air in the closet uniformly moist.

After 24 hours in moist air, the test pieces for longer periods of time should be immersed in water maintained as near 21 degrees C. (70 degrees F.) as practicable; they may be stored in tanks or pans, which should be of non corrodible material.

Tensile Strength.

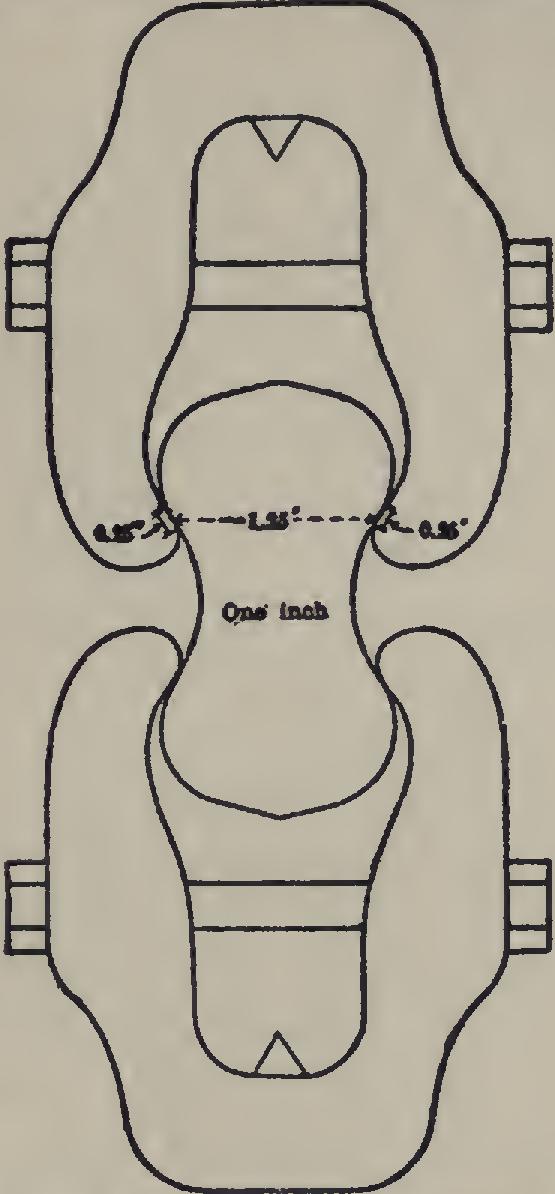

Tests for tensile strength may be made on any standard testing machine. Solid metal clips of the form shown in Fig. 5 are recommended. The clips should be used without cushioning at the points of contact with the test specimen. The bearing at each point of contact should be inch wide, and the distance between the centers of contact on the same clip should be inches.

Test pieces should be tested to the point of failure or rupture, as soon as they are removed from the water. Care should be observed to center the briquettes in the testing machine, as cross-strains, produced by improper centering, tend to lower the breaking strength. The load should not be applied too suddenly, as it may produce vibration, the shock from which often breaks the briquette before the ultimate strength is reached. Care must be taken that the clips and the sides of the briquette be clean Fig. 6. Form of Clip Used for Holding Cement Briquette in Test for Tensile Strength.

and free from grains of sand or dirt, which would prevent a good bearing. The load should be applied at the rate of 600 lbs. per minute. The average of the briquettes of each sample tested should be taken as the test, excluding any of the results which are manifestly faulty.

Constancy of Volume. The object of this test is to detect those qualities—if any are present—which tend to destroy the strength and durability of a cement. As it is highly essential to determine such qualities at once, tests of this character are generally made in a very short time, and are known, therefore, as accelerated tests. Failure is revealed by crack ing, checking, swelling, distortion, or disinte gration, or all of these phenomena. A cement which remains perfectly sound is said to be of constant volume.

Tests for constancy of volume are divided into two classes: (1) Normal tests, or those made in either air or water maintained at about 21 degrees C. (70 degrees F.) ; and (2) Accel

erated tests, or those made in air, steam, or water at a temperature of 45 degrees C. (115 degrees F.) and upward. The test pieces should be allowed to remain 24 hours in moist air before immersion in water or steam, or preservation in air.

For these tests, pats about 71/2 cm. (2.95 in.) in diameter, cm. (0.49 in.) thick at the cen ter, and tapering to a thin edge, should be made, upon a clean glass plate about 10 cm. (3.94 in.) square, from cement paste of normal consist ency. In making the pats, the greatest care should be exercised to avoid initial strains due to moulding or to too rapid drying-out during the first 24 hours. The pats should be preserved under the most uniform conditions possible, and rapid changes of temperature should be avoided.

In the normal test, a pat is immersed in water maintained as near 21 degrees C. (70 degrees F.) as possible, for 28 days, and ob served at intervals. A similar pat, after 24 hours in moist air, is maintained in air at ordi nary temperature, and observed at intervals.

In

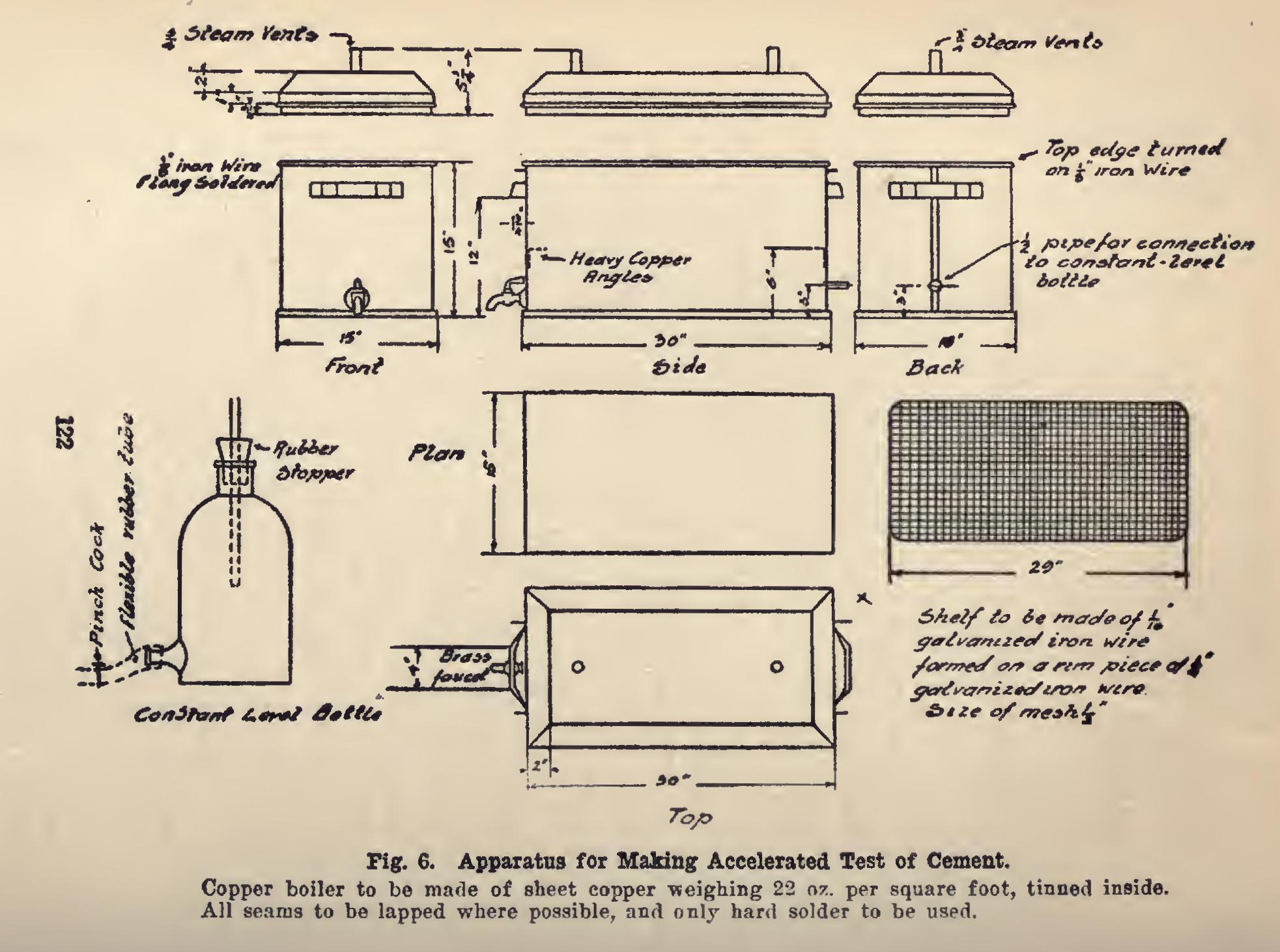

the accelerated test, a pat is exposed in any convenient way in an atmosphere of steam, above boiling water, in a loosely closed vessel, for 5 hours. To accomplish this, the use of the apparatus illustrated in detail in Fig. 6 is recommended.

To pass these tests satisfactorily, the pats should remain firm and hard, and show no signs of cracking, distortion, or disintegration. Should the pat leave the plate, distortion may be detected best with a straight-edge applied to the surface which was in contact with the plate.

In

the present state of our knowledge, it cannot be said that cement should necessarily be condemned simply for failure to pass the accelerated tests; nor can a cement be consid ered entirely satisfactory simply because it has passed these tests. Accelerated tests, there fore, are to be taken merely as precautionary measures, not as infallible and final guides. Should a cement fail to meet the requirements of the accelerated test, it may be kept for 28 days, and then tested again. Failure at this time would probably indicate sufficient cause for rejection, though passing the test—as already noted—would not necessarily indicate perfect soundness, and the result of other tests should also be taken into consideration.