Concrete Pile Foundations

shell, core, piles, piling, driving and steel

CONCRETE PILE FOUNDATIONS The second use of reinforced concrete in foundations, referred to as the use of concrete piles, is a factor which promises to be of great value in the future. The constantly increasing use of concrete piling is a substantial recogni tion of the claims made for it by its advocates. The on© advantage over concrete piling that wood piling has possessed—namely, low initial eesst—is rapidly disappearing, because of the growing scarcity of the available lumber supply due to constant deforestation. The absolute permanence of concrete piling, its freedom from the dangers that threaten the integrity of wood piling—rot, over-driving, the attacks of boring animals, etc.,—its low ultimate cost, and the fact that its constituent materials may be obtained almost anywhere, are factors that in time will drive wood piling out of general practice.

There are two general methods of concrete pile construction: those constructed in place, and those moulded or rolled in advance and driven by methods similar to those used for driving wooden piles. In the first method some form of collapsible steel core, encased in a closely fitting shell of suitable material, is driven in the usual manner, the core withdrawn and the shell filled with concrete. Piles constructed in this man ner may be either plain or reinforced, depending largely upon the character of the work for which they are to be used. In the second method it is quite essential that they be reinforced to with stand the strains to which they are subjected in handling and driving.

In certain cases concrete piles are an eco nomical substitute for deep pier foundations. Six types of patented reinforced concrete piles are shown in the accompanying illustrations.

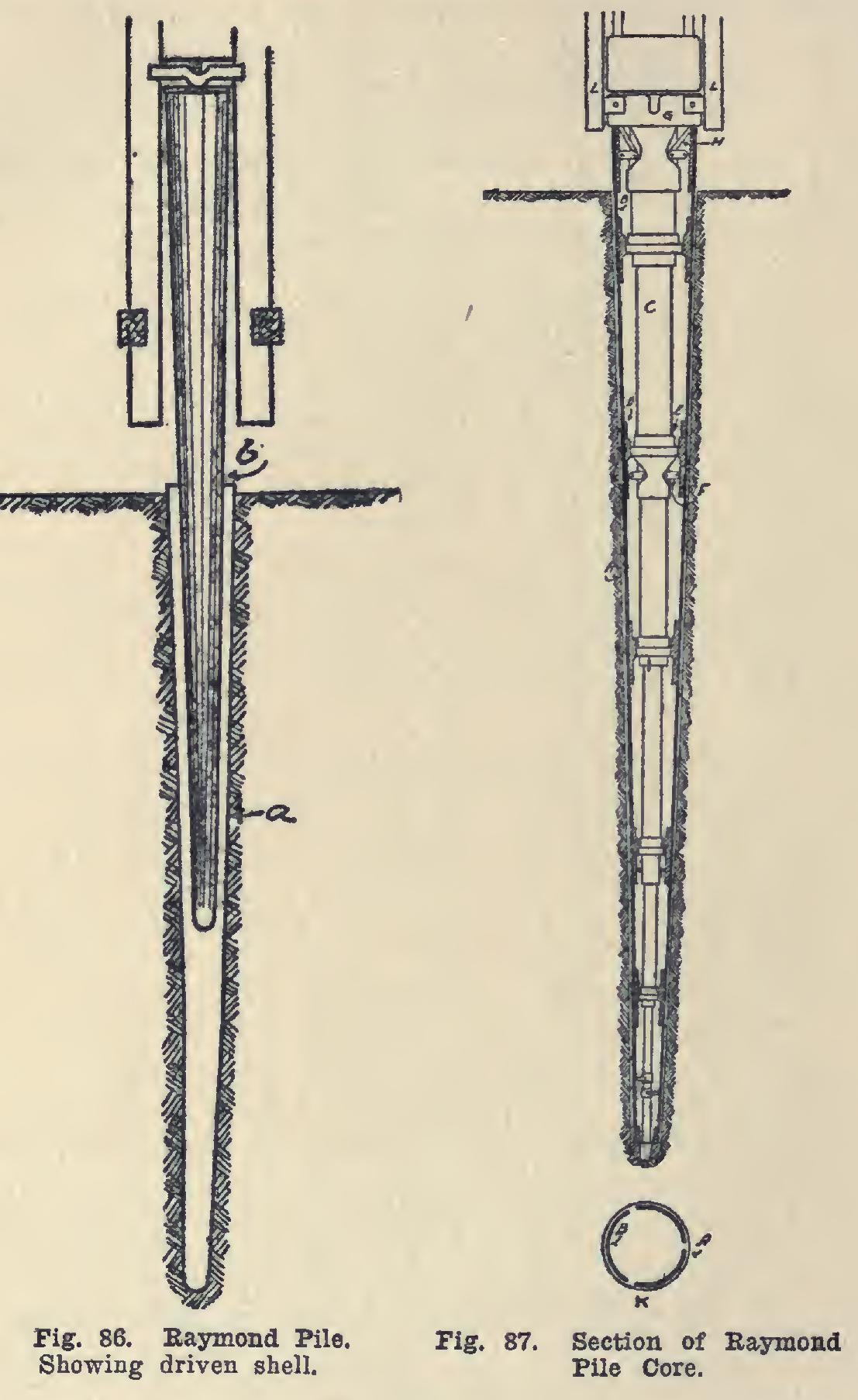

The Simplex pile is constructed by driving a hollow shell with a point to the full depth, and gradually raising the shell as the concrete is placed in the hole thus made. The process, using an alligator point, which opens when the shell is pulled, is shown in Fig. 85 at the left.

Sometimes a solid point made of cast iron is used, which is left in the ground.

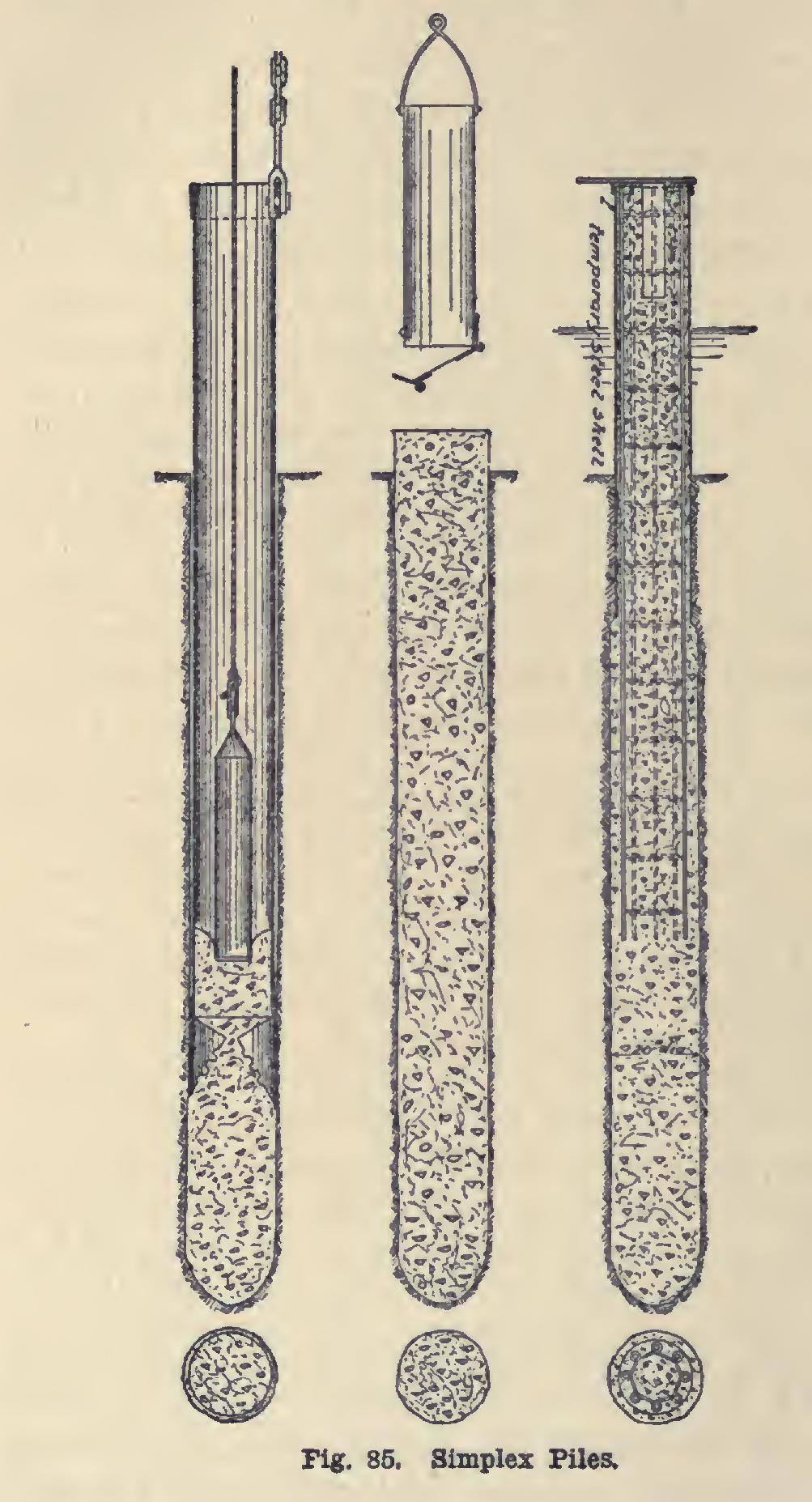

Raymond concrete piles

are made by driving a tapering sheet steel shell to refusal by means of a collapsible steel core, withdrawing the core, and thereupon filling the shell with concrete.

The shell consists of a number of circular sections that are formed by uniting the vertical edges of two pieces of 18 to 20 gauge sheet steel, bent into shape by a cornice brake. The diameters of the sections range in a decreas ing ratio from the uppermost section down to the point or boot. The latter is stamped from a single piece of 16 gauge stock.

The core is composed of three steel segments forming a tapering cylinder or cone. The segments are separated or brought together through the action of a series of wedges. A driving cap is attached to the head of the core.

The shell is assembled by slipping the various sections composing it over the core, the segments of which are expanded at this stage. Placing the boot in position over the point of the core completes the shell. The sections overlap sufficiently to exclude any soil, water, or other foreign substances that might otherwise gain admission into the shell while it is being placed.

After the core is completely encased in the shell, it is driven to refusal. The core is thereupon withdrawn by bringing the segments together, or "collapsing" the core, as the operation is termed. The shell, which is of suffi cient strength to retain its shape after the withdrawal of the core, remains permanently in the ground and forms a mould or form for,the concrete. Fig. 86 shows the core of a Raymond pile collapsed and partly withdrawn from the shell.

Before being filled the shell is subjected to careful inspection. After inspection, thoroughly mixed concrete, composed of one part good Portland cement, three parts sharp sand, and five parts crushed stone or gravel of suitable size, is poured in, being carefully tamped until the shell is filled.