Miscellaneous Uses of Reinforced Concrete

feet, cement, blocks, cubic, dam, pounds and following

"No. 2 Concrete. For use on the outside of 4-foot off-take pipes, the lower valve chamber, filling cut-off trenches and tunnels and the hood of valve chamber on down-stream side, was composed of the following propor tions: Cement, 375 pounds; sand, 10 cubic feet; blue stone and shivers, 20 cubic feet; the bluestone and shivers being of the same proportions and sizes as for No. 1 concrete.

"No. 3 Concrete.

For use in the down-stream face of the dam, in the hearting work where voids are large enough, filling shaft, and between the backs of blocks and facing boards, were composed of the following pro portions: Cement, 375 pounds; sand, cubic feet; and 3-inch bluestone, 20 cubic feet. Approved sandstone accepted in lieu of bluestone.

"Special Cement Mortar.

For use in bedding the up-stream blocks, was composed of the following pro portions: Cement, 375 pounds; sand, cubic feet.

"Cement Mortar.

For use in bedding hearting blocks and between blocks where the space was too small for No. 3 concrete, and immediately surrounding the 4-foot off-take pipes, was composed of the following propor tions: Cement, 375 pounds; sand, cubic feet.

"Where required, metal work in the form of rails, bars, or other shapes, was bedded in the concrete filling between the up-stream and down-stream facework of the dam; and the hearting blocks of masonry were car ried through from the up-stream to the down-stream face of the dam in sections of concrete specially intro duced for that purpose between the masonry blocks." The contractor was permitted, for the convenience of executing the work, to carry up piers within the dam for the support of roads or cranes, to such heights as were necessary, provided always that such height, the sectional area in plan, the outline in plan, and the position in the dam of such pier or piers had been approved of by the engineer.

The lining of the main shafts, inlets from penstocks, and outlets to cast-iron pipes from the shafts, were of No. 1 concrete, 12 inches and 2 feet thick, carefully cut and worked on the timber framing so as to make a sound surface. This work was brought up with the rest of the work, so as to insure its bonding and setting at the same time.

Immediately the framing was removed, the face of the concrete, after any inequalities or defects had been filled with special cement mortar, was coated with cement wash, two coats being used where 12 inches thick, and one coat where 2 feet thick.

The sandstone used for the blocks had a weight of 140 pounds per cubic foot, and a crushing strength of 276.3 tons per square foot on a block of 12-inch cube.

Tests of the compressive strength of all concrete and mortar used were made constantly during the prog ress of the work, and the following are average results; In Tons per Square Foot 30 days 60 days 90 days No. 1 concrete 120.53 102.17 116.07 No. 2 concrete 70.93 70.83 No. 3 concrete 61.16 96.81 110.77 Mortar 61.42 67.68 102.66 The cost of the works is approximately $1,650,000.

The plant used on the work cost about $166,000, half of which sum only has been included in above total cost, the balance being debited to other works on which the plant will be used.

The work of construction was commenced in October, 1902, under the system of day labor. The actual work of building the dam occupied four years and eleven months, and was carried on day and night.

Reservoir Roofs. Two of the largest roofs in the world, covering approximately 16 acres, and embodying building methods and material never before adapted to such a purpose, have been constructed at Los Angeles, California.

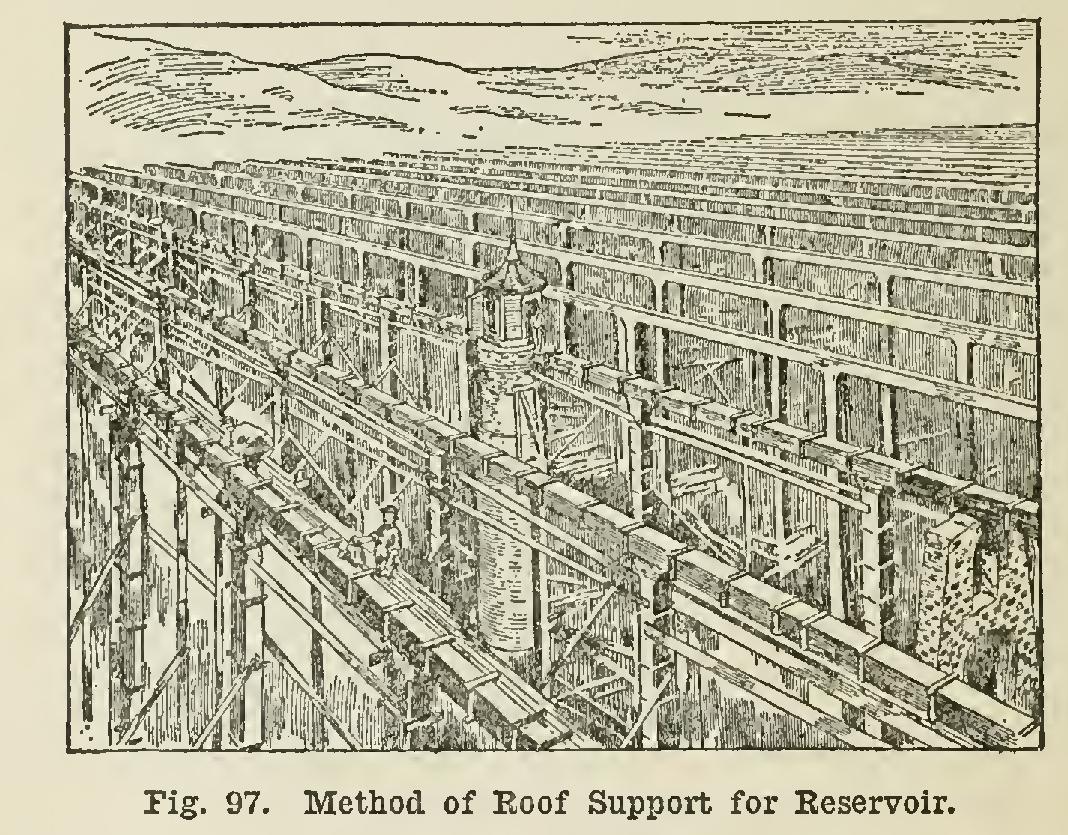

Each is on a city reservoir, one 10 acres in ex tent and the other 6, and reinforced concrete piers are used as supports. In the "Bellevue," the smaller of the two reservoirs, these piers are 47 feet long, and submerged over 40 feet; and on the other, the "Ivanhoe," 27 feet. See Fig. 97.

There is a veritable forest of piers-330 of them—in the Bellevue reservoir. Each rests on a 30-inch base, running thence to 16 by 16 inches, and finally to 12 by 12 inches at the top. The girders that span the huge "well on a hill," as the reservoir is often called because of its commanding location several hundred feet above the surrounding country, are 8 by 14 inches at the ends, 304 feet long at the widest part of the tank, and 115 feet at its narrowest—and all of reinforced concrete. The roof placed upon them, it is declared by the engineers in charge, will last practically forever. It is painted green, to harmonize with the landscape.