Hot-Water Supply

water, temperature, coil, square, steam, surface, foot and heat

Since a heat unit is the amount of heat re quired to raise one pound of water one degree in temperature, then, in order to raise 250 lbs. 90 degrees, we shall require a total of 250X90= 22,500 heat units.

The steam pressure is 2 lbs., gauge.

Temperature of the steam at this pressure is 220°.

Average temperature of water is found by adding maximum and minimum, and dividing by 2; thus, (70+160)-:-2=230÷2=115°, aver age temperature of water.

Average difference in temperature between steam and water is 220-115=105 degrees.

It is a well-known fact that steam coils sur rounded by air at a temperature of 70 degrees give off roughly about 2 heat units per degree difference in temperature per hour; but when placed in water they condense steam approxi mately 50 times as fast per degree difference in temperature. It is also a well-known fact that one square foot of heating surface will transmit about 100 heat units per hour per degree differ ence in temperature. Therefore each square foot of steam coil in the boiler water will give off 105x 100=10,500 heat units per hour.

The total square feet of heating surface re quired will therefore be 22,500÷10,500.2.14 square feet approximately.

Now, since it requires 2.9 feet of 1-inch pipe to equal 1 square foot of heating surface, there foro 2.9 X2.14=6 feet 3 inches, approximately, of 1-inch pipe in the coil required for heating the 30 gallons from a cold-water temperature of 70° to a temperature of 160° with steam at 2 lbs. pressure—or about 1 square foot of heating sur face in the coil to each 14 gallons of water in the boiler.

The ordinary range-boiler with a steam coil will give entire satisfaction if the steam coil is based on 1 linear foot of 1-inch pipe to each 5 gallons of water to be heated per hour, the water being heated from a temperature of 60° to one of 160°; and this is the basis on which they are constructed.

The same method of calculation can be used for steam or water at varying temperatures, and for lesser or greater quantities of water. The ratio of 1 square foot of heating surface to each 15 gallons of water to be heated is based on iron pipe coils; and the ratio for brass or copper piping will be about 1 square foot to each 20 or 25 gallons, owing to brass or copper being a better conductor than iron.

The size of the pipe coil necessary for heat ing the water when coils are placed in a stove, furnace, or boiler, can be determined by allow ing square inches of surface actually exposed to the fire, for each gallon of water to be heated.

This would mean 75 square inches of surface for a 30-gallon boiler, or about 2 feet of pipe, or about 1 foot 6 inches of 1-inch pipe. This piping should have the ends well reamed of the burr that is left by the cutters when cut ting off the pipe, as the burr would have a tend ency to cause the coil to choke or lime up if the water should be dirty.

The above calculation is based on heating the water in the boiler in one hour. If it is de sired to heat it faster, a greater amount of sur face must be used, and the surface required can be readily determined from the above data.

The proper size of water-back or coil for a range boiler must be carefully determined. The use of a coil that has too much heating surface will result in considerable annoyance to the occu pants of the building, from the rumbling noises that will be caused by the water boiling. This is a very common mistake, and should be watched. On the other hand, do not make the coil too small, as it will simply have to be re placed by a larger, and here is where the plum ber is apt to go to the other extreme and put in a coil too large. A careful following of the facts stated above will enable one to install the proper size at once.

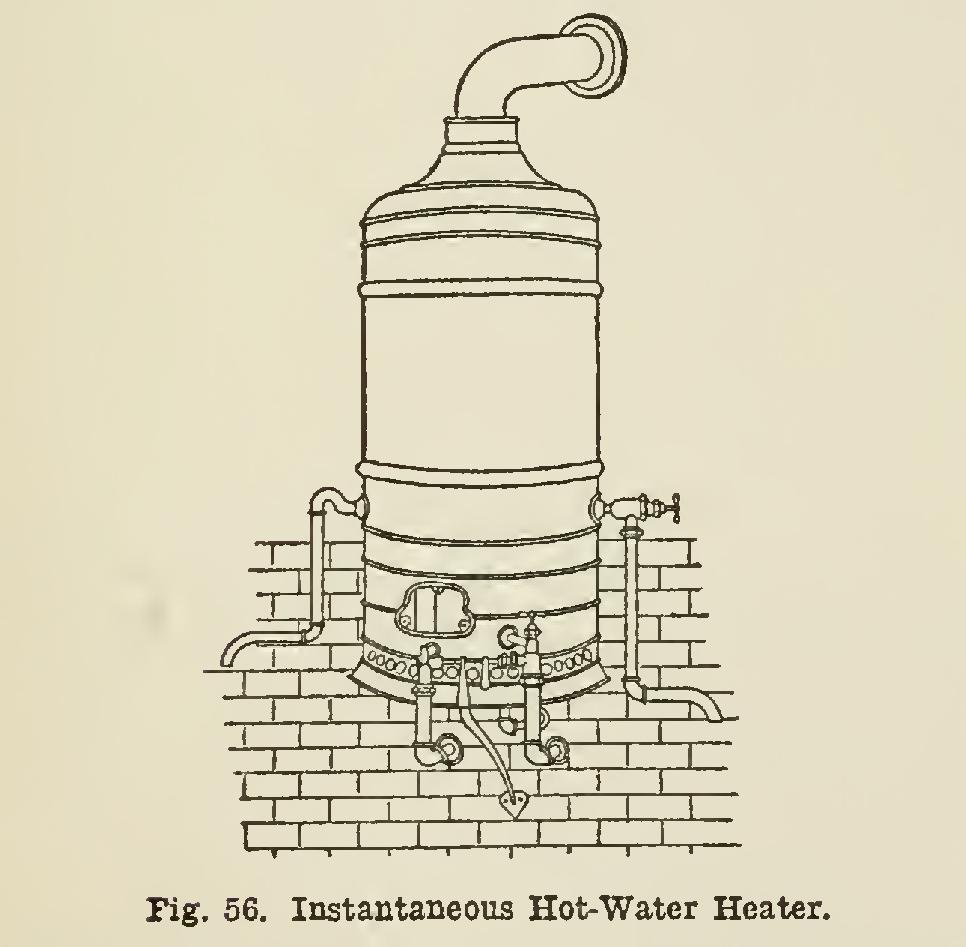

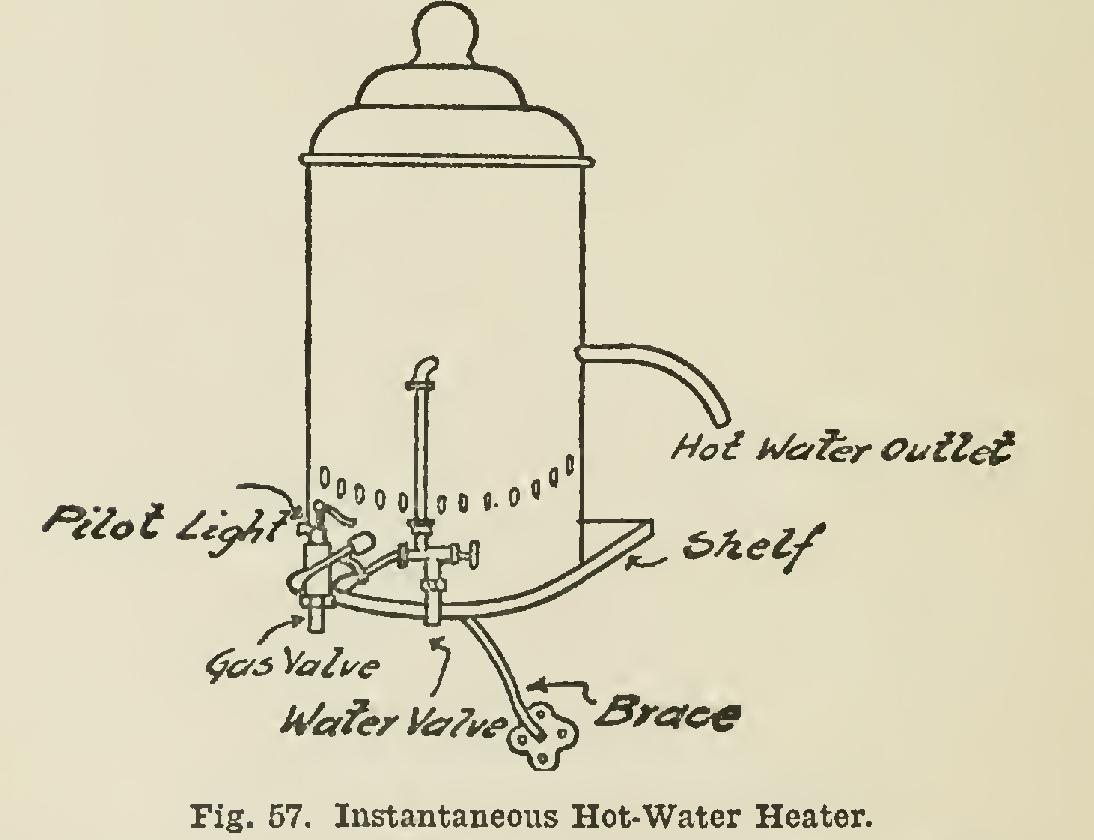

Instantaneous Hot-Water Heaters. Figs. 56 and 57 show common types of instantaneous hot water heaters. Their operation is as follows: Water and gas or gasoline being connected to the heater at the proper places, the water, on being turned on, is carried to the top of the heater, where it is distributed in a thin sheet or small streams flowing downward over a sheet metal cylinder which forms part of the interior construction of the heater, and thus becomes warmed, after which it is carried to point de sired. These heaters have the water and gas valves so constructed that it is impossible to turn on the gas without also turning on the water, and the burning of the heater is thus avoided. A vent-pipe should always be attached to the top of a heater, and carried to some convenient flue, although it is claimed for the heater shown in Fig. 57 that no flue is necessary. A drip-pipe should be attached to the drip-pan or shelf on which the heater rests, to take care of the con densation which will occur at times.