Hot-Water Supply

boiler, water, range, fig, pipe and heating

HOT-WATER SUPPLY There are various ways of heating the water for domestic and other uses. We shall first take up the manner of heating by range boilers and coils or water-backs, passing on to automatic and instantaneous heaters.

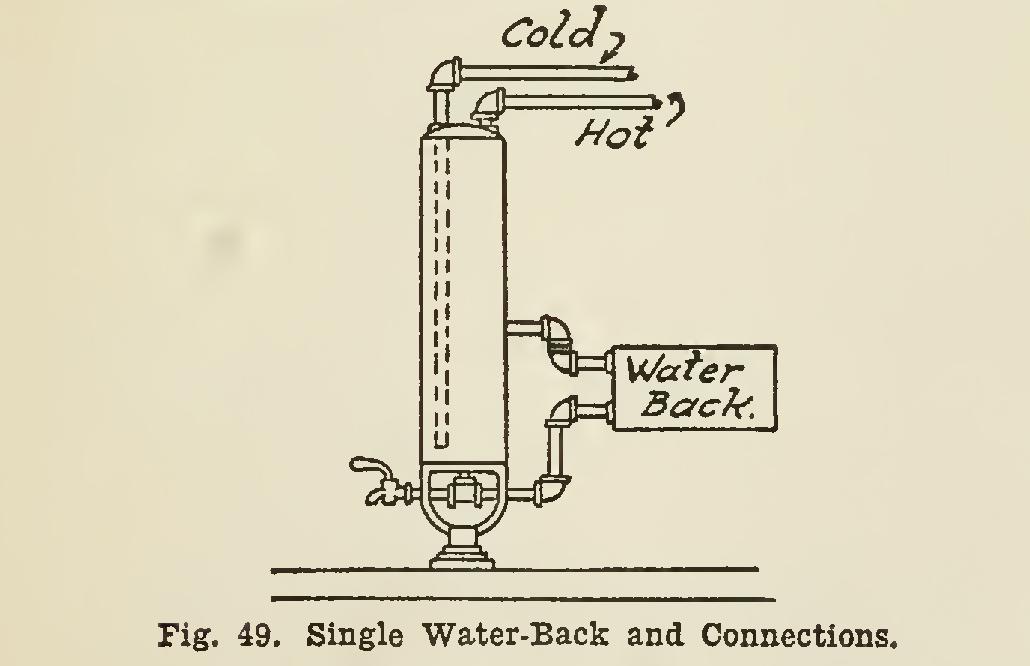

Fig. 49 shows the common method of con necting a range boiler to a pipe coil or a cast iron water-back. The sketch is self-explanatory. If lead pipe is used, care must be taken that there will be no pockets for the air to collect in, as this will seriously interfere with the working of the job. Lead pipe does not give as good sat isfaction for the hot-water pipe from the water back to the boiler, .as does the use of brass or iron, since the expansion and contraction due to alternate heating and cooling have a tendency to stretch the lead pipe, and in time will start a leak. Galvanized-iron or brass piping is slowly replacing the use of lead pipe, and in some jobs there is no lead pipe used whatever. Fig. 49 shows a connection to one water-back only.

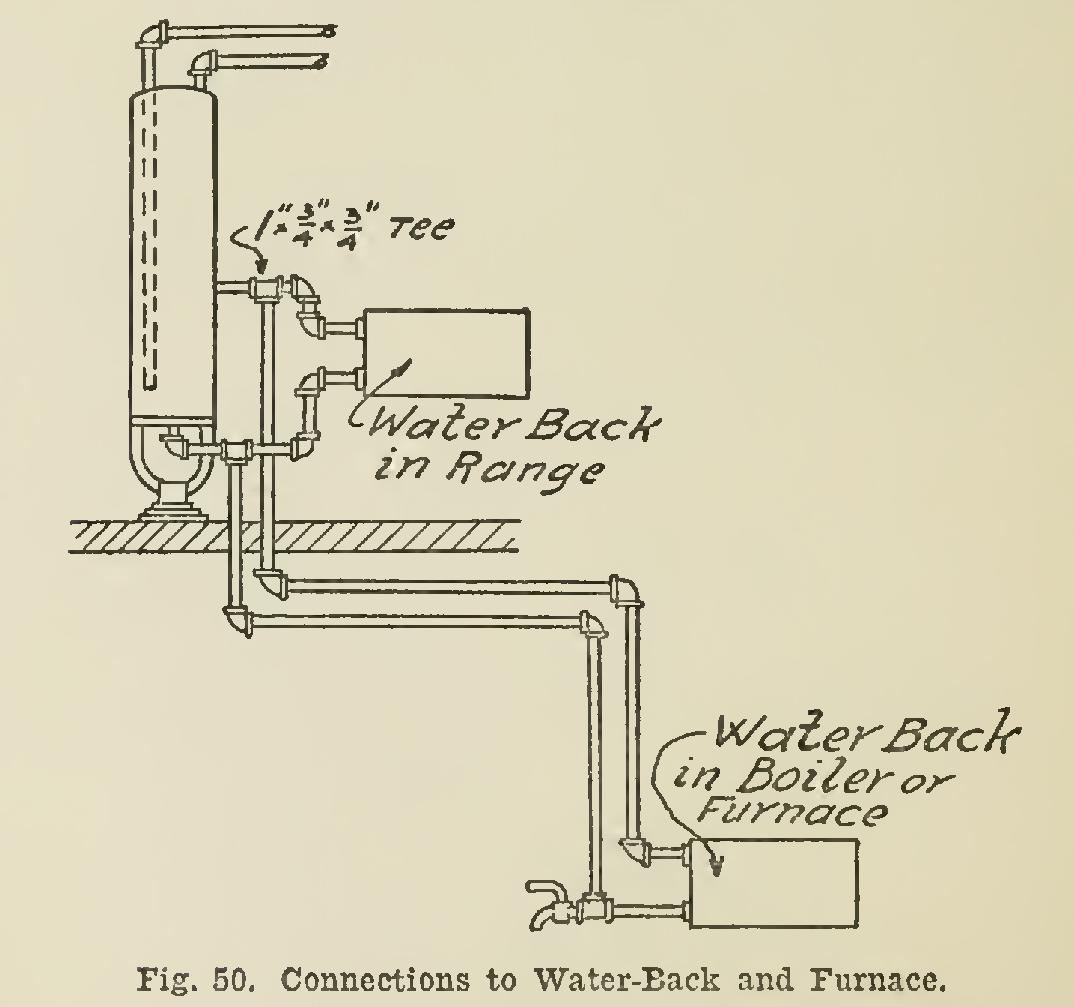

Fig. 50 shows the same form of connection for the water-back on the first floor, but also shows a connection to the furnace or boiler in the basement. The sediment cock, it will be noted, is placed at the low point in the basement, whereas, on the first floor, it was placed under the range boiler. Any number of water-backs can be connected to a single boiler, if due care is taken in making the connections, so that the hot-water currents will not buck against each other, and reverse the water travel or cause hammering.

Fig. 51 illustrates about the same thing as Fig. 50, but shows a gas-heater also connected. This heater, if desired—as, for example, in hot weather in summer-time—will work independ ently of the other means of heating the water in the boiler; or they may all be working at once, without interfering with the action of one an other. In some cases the gas-heater is con nected to the boiler alone, and is the only means of heating the water. This very often occurs in %apartment houses or "fiat buildings," where the structure is heated by steam, and where gas stoves are used for cooking; or the gas stove may have a water-back connected to the range boiler.

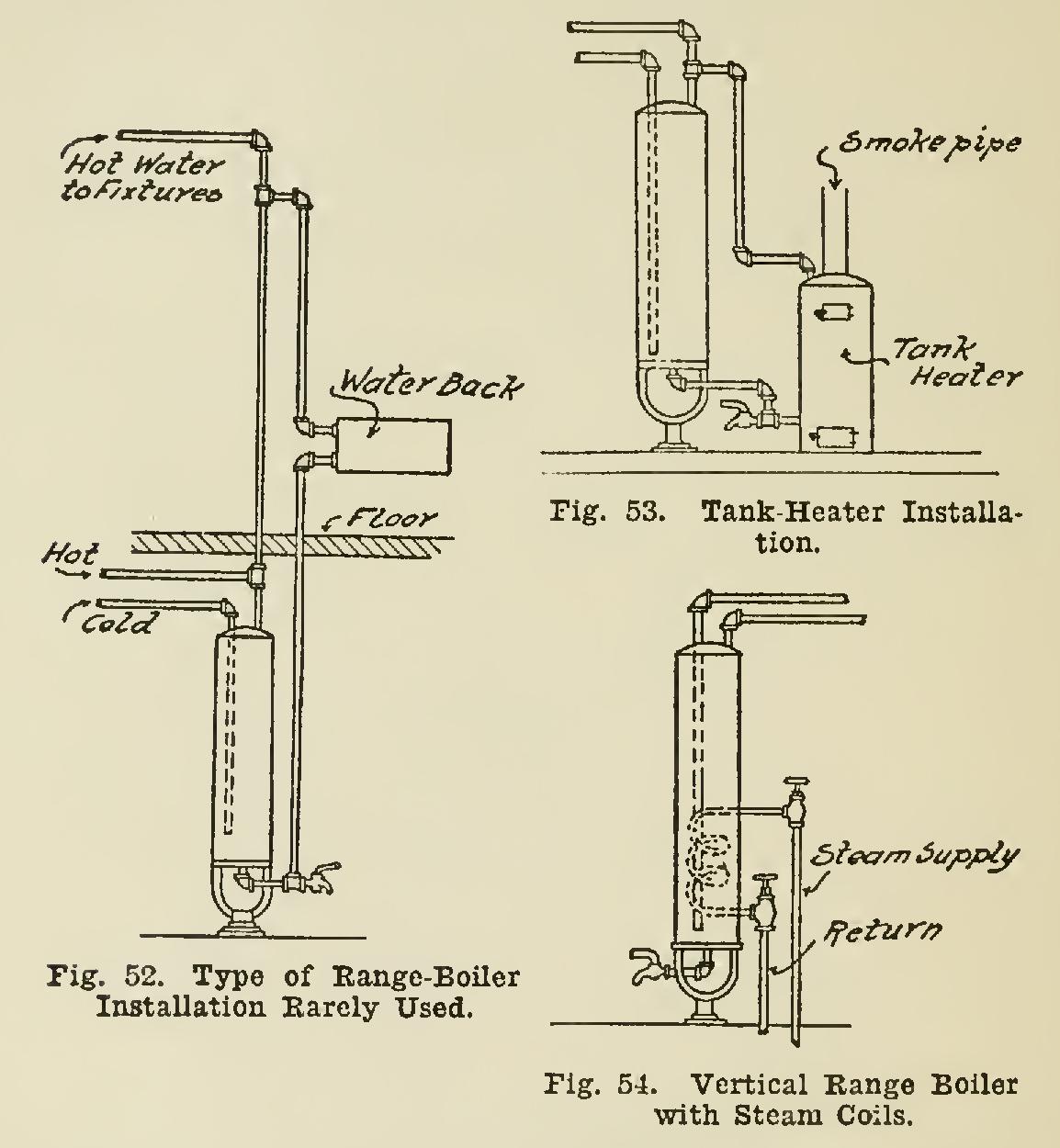

Fig. 52 shows a type of range-boiler installa tion which is very rarely used and is not very successful in operation, as the circulation is apt to be sluggish. It will work as shown in the sketch; and the higher the loop extends above the top of the boiler, the faster will be the cir culation; but the use of this type of installation should, if possible, be avoided. If, however, this type must be used, the hot water must be taken from the top of the loop, in order to free the loop from the air which will accumulate at that point.

Another form of hot-water heater in very frequent use is shown in Fig. 53—called a tank heater. Heaters of this type are constructed in various styles and sizes to meet all requirements. The sketch shows the manner of connecting to the range boiler. These heaters are used exten sively where large quantities of hot water are desired, and are very satisfactory.

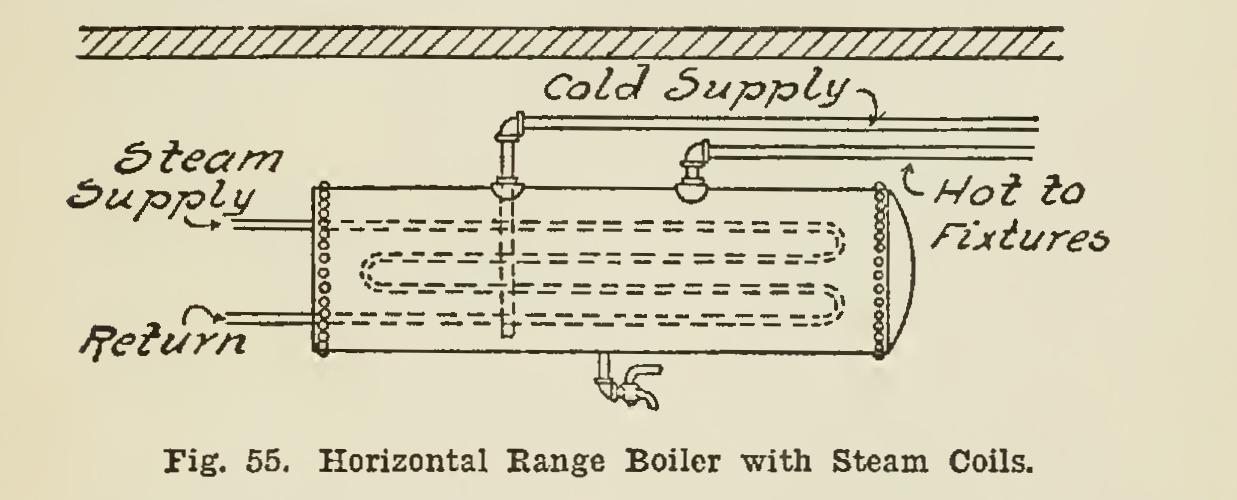

Figs. 54 and 55 show different types of range boilers with steam coils therein, by which the water in the boilers is indirectly heated. This is an economical method of heating water where a building is heated by steam, and where there is exhaust steam available. By its use the cost of heating water is reduced practically to nothing.

Sizes of Coils. As any plumber may be called upon to install a boiler of this type, we shall figure out the size of steam coil necessary to raise the temperature of the water in a 30 gallon range boiler from the average tempera ture of the water supply, say 70 degrees, to a . temperature of 160 degrees, that desired kfia6 Since a gallon of water weighs 81/2 and the boiler contains 30 gallons, it follows that pounds, the weight of water in the boiler.

The increase in temperature desired is from 70° to 160°—a total of 90 degrees, since 160 70=90.