Use and Care of Tools

edge, bevel, tool, cut, angle, stone, chisel and cutting

Chisels and Chiseling. To do good work, a chisel must be kept very sharp, and special care must be taken in handling it. Both hands should, at all times, be kept back of the cutting edge.

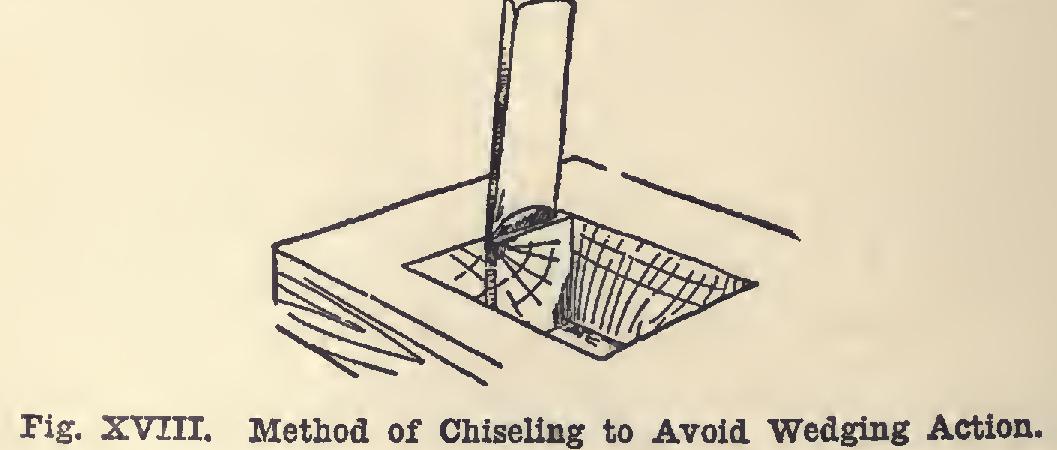

The action of a chisel driven into the wood with a mallet is somewhat similar to that of a wedge. This must be taken into account when cutting dadoes, mortises, etc., where it is de sired to cut away the waste exactly to a given line. If the chisel were beveled on two sides the action would be the same as that of a wedge; that is, the wood would be pushed to either side equally. Since the bevel is on one side only, beginners are prone to think that the wedging takes place on one side only, the bevel side. Most of the wedging does take place on the wood at the bevel side, but there is enough pres sure against the bevel to force the flat side of the chisel over the line slightly onto the part which it is not desired to cut. To overcome this action, chisel a line parallel to the given line, about one thirty-second of an inch away from it, on the waste. When the opening has been cut to depth, the chisel may be set exactly in the given line and driven to depth. The narrow margin of waste wood breaks off; the pressure against the bevel is therefore almost nothing (Fig. XVIII).

Grinding Beveled-Edge Tools.

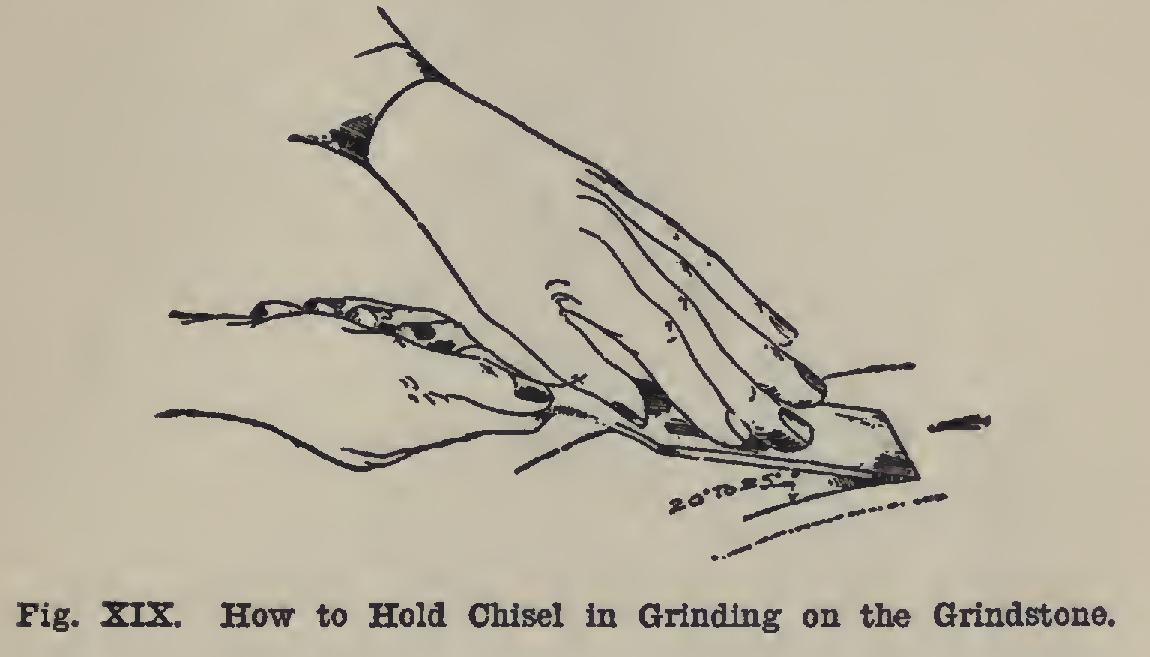

When edged tools become rounded over by repeated whet tings, or when they are nicked too deeply for the oil-stone to remove the nicks, the grindstone is needed to cut the metal to the proper angle. Fig. XTX shows the manner of holding the chisel upon the stone. The tool must be held firmly and at the same angle. This angle will depend upon the temper of the tool and the kind of wood to be cut, whether hard or soft, soft wood allowing the use of a sharper angle. On plane irons the length of bevel or grind should be three-sixteenths or one-fourth of an inch; on chisels, three-eighths or one-half an inch. The tool should not be kept in the middle of the stone but should be moved from right to left and vice versa across it as the grinding proceeds, that the surface of the stone may be worn as evenly as possible.

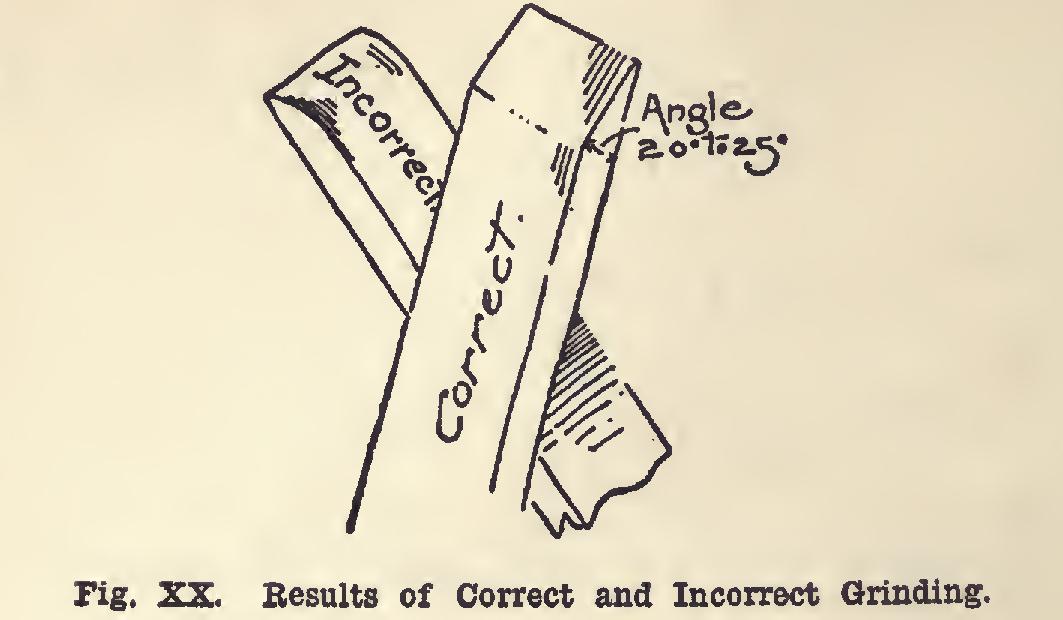

The pressure of the left hand should be so applied that the stone will cut straight across the blade. Examine the tool often, being care ful to replace it each time as nearly as possible at the same angle. Fig. XX shows the flat bevel which is to be obtained, also the rounded effect caused by frequent changing of the angle at which the tool is held.

Grindstones are usually turned towards the tool, because in doing so they will cut faster. Water is caused to flow on the stone for two reasons—to keep the edge of the tool from be ing burned or softened by the heat which fric tion would generate, and to wash off the par ticles of steel and stone, thus keeping the cut ting surface clean so that it may cut the more freely.

Sharpening the Chisel.

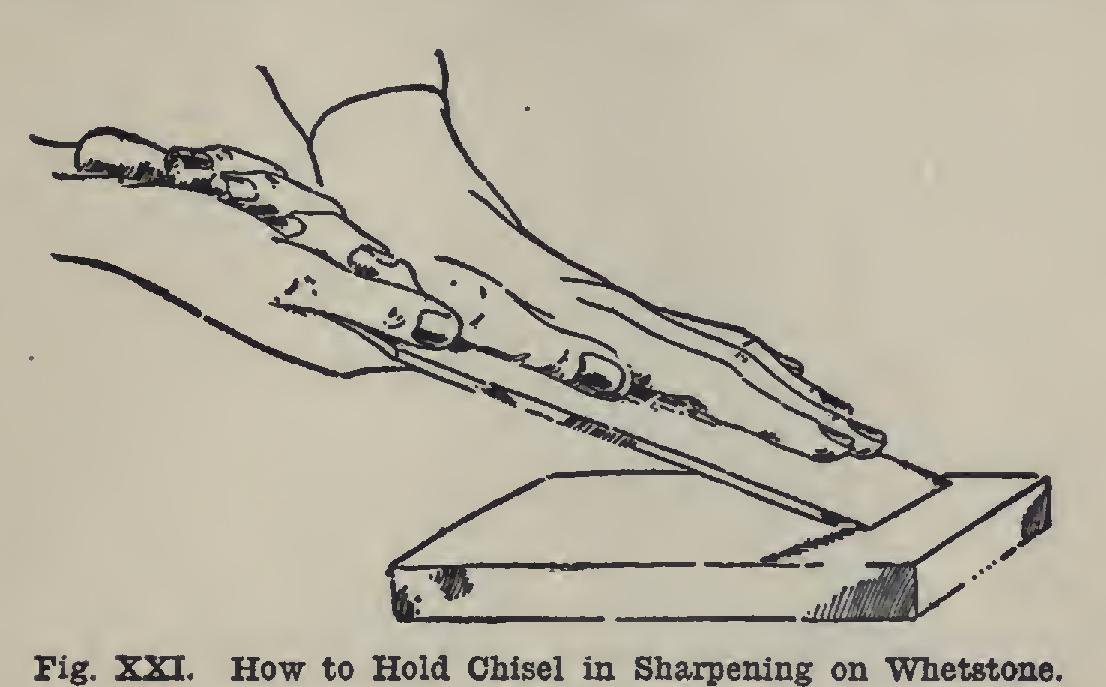

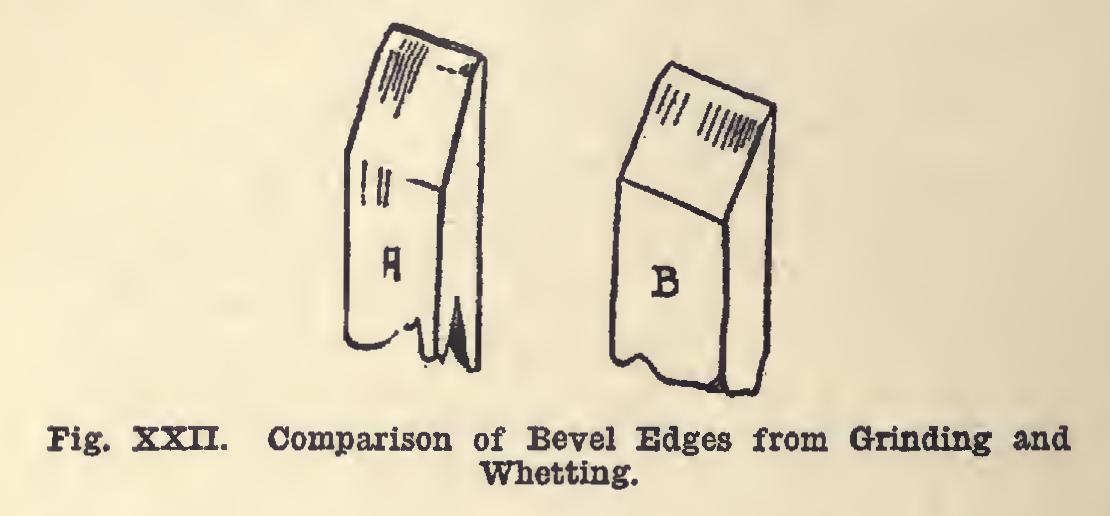

Hold the tool as shown in Fig. XXI. Suppose the grinding pro duced a bevel of about twenty-five degrees, in whetting, effort should be made to hold the blade so as to produce an angle slightly greater than this. The amount shown in Fig. XXII (A and B) is exaggerated. The aim at all times should be to keep this second angle as near like the first as is possible, and still get a straight bevel to the cutting edge.

To get the tool into proper position, lay it flat on the stone, with the beveled edge resting in the oil which has previously been placed on the stone. The oil should be drawn to the place where the whetting is to be done, the back edge of the bevel being used to push and draw it to place. Gradually raise the handle of the tool until the oil is expelled from under the cutting edge; it is then in position. Use just enough oil to keep the surface well moistened where the whetting is being done.

Rub the chisel back and forth, keeping it at the same angle all the time. A rocking motion and frequent change of angle will result in a rounded end instead of a straight bevel. Some workmen prefer to give the blade a circular instead of the forward and backward movement.

To remove the feather or wire edge which frequently results from over-whetting or from grinding, proceed as follows: Hold the tool with the flat side down, just a little above the stone, with the handle just a very little higher than the cutting edge. In one stroke push the cut ting edge forward and down on the stone, at • the same time lowering the rear end to a level with the cutting edge. The effect of this move ment is to turn the wire edge under and cut it off. If the first attempt does not remove it, whet the bevel just enough to turn the edge back on the flat side and try again. The pres ence of a feather edge is detected by rubbing the fingers along the flat side over the cutting edge.