Use and Care of Tools

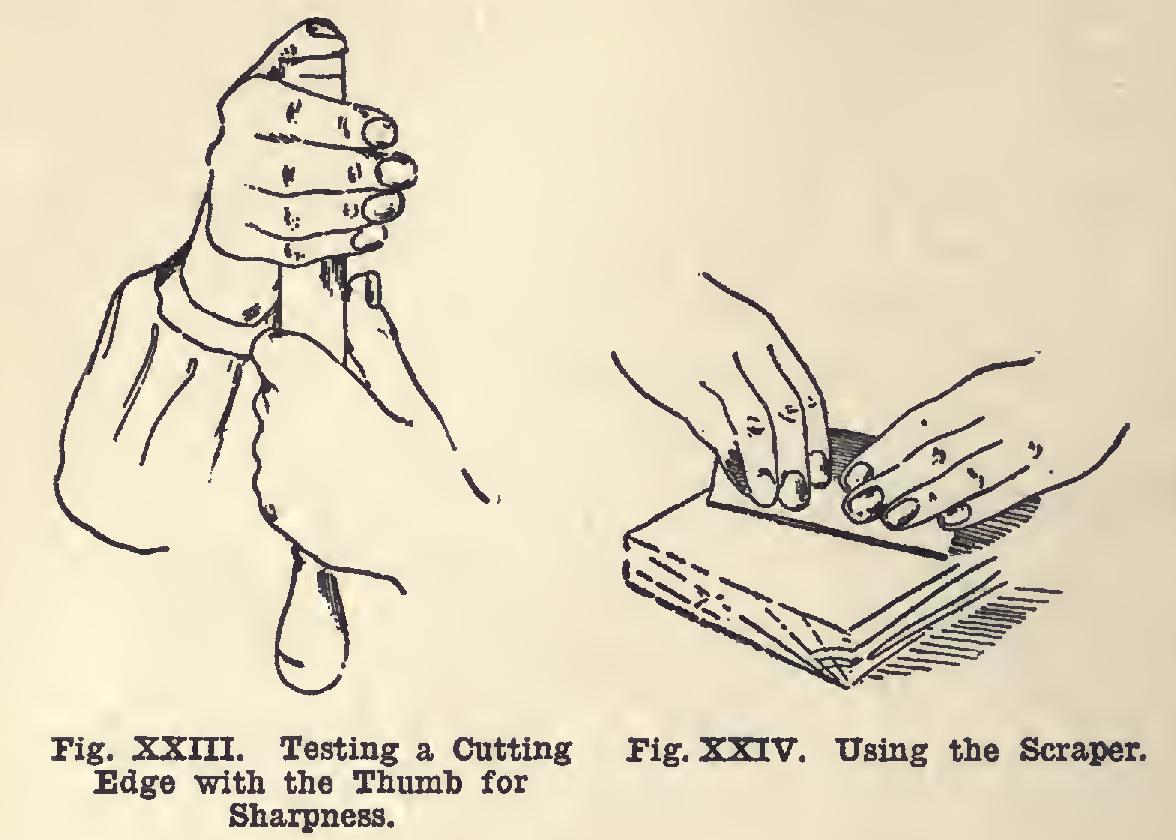

edge, scraper, tool, cutting, thumb and fig

Sharpening Plane-Irons.

Plane-irons are sharpened straight across like the chisel, with the exception of the jack-plane, as previously noted. Their corners, however, are very slightly rounded off to prevent their leaving marks on the wood. Where one plane is made to serve the purpose of smooth, jack, and fore-plane, it should be ground straight across. In whetting, increase the pressure on the edges alternately so as to turn up a heavier feather edge there than in the middle, thus rounding the whole end very slightly. This feather edge may be removed in the usual manner.

To Tell Whether a Tool is Sharp or Not. Examine the cutting edge, holding the tool toward the light. If the tool is dull, the cutting edge will appear as a white line, the broader the line the blunter the edge (Fig. XXII, A). If the tool is sharp, no white line can be seen (Fig. XXII, B).

A better way—the method a mechanic would use—is to test the edge by drawing the thumb along it lightly (Fig. =En). If the tool is sharp, one can feel the edge "taking hold." If dull, the thumb will slide along the edge as it would along the back of a knife blade.

Good judgment is necessary in this test, or a cut on the thumb may be the result. No pres sure is required, just a touch along the edge at various points. The cutting edge, if sharp, cuts the outer layer, the callous part of the ball of the thumb, just a little. The sense of feeling is so keen that the effect is felt long before any in jury need be done the thumb. If the tool is dull, no cutting will be felt unless greater pressure than is necessary for the test is exerted. Do not use the finger, since it is not calloused as is the thumb.

Scraping. In

smoothing hardwood surfaces, a scraper will be found helpful. If the grain should happen to be crossed or curled, a scraper will become a necessity. The plane-iron may be made ever so sharp and the cap-iron set ever so close to the cutting edge, still the surface of some woods will tear. Sandpaper must not bedepended upon to smooth a torn surface.

Cabinet scrapers for plane and convex sur face work are rectangular pieces of saw steel.

Beginners frequently mistake surfaces which have been planed at a mill for smooth surfaces. They are not; and, unless the "hills and hol lows" which extend across the surface of every mill-planed piece of lumber are removed before the finish or stain or filler is applied, the result will be very unsatisfactory.

These "hills and hollows" are present even in the smoothest of mill-planed surfaces. The reason is easily understood. When a board is mill-planed, it is run through a machine which has a flat bed over which the board is moved and above which revolve two knives. Unless the grain of wood is very badly crossed or curled, it will be found very much easier, and time will be saved, if the mill-marks are removed with a smooth-plane before the scraper is applied.

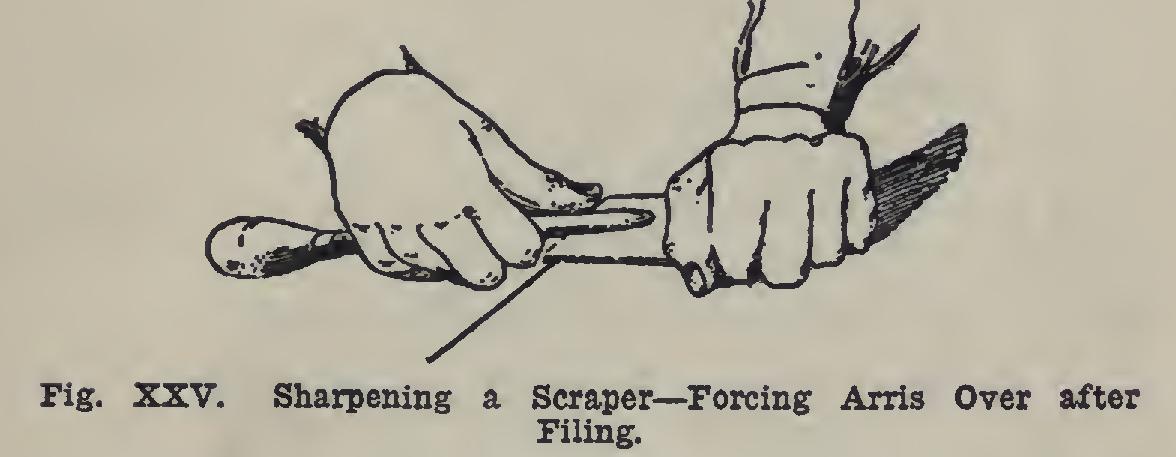

Scrapers may be pushed or pulled (Fig. XXIV). When properly sharpened, thin silky shavings will be cut off. The cutting edge of a scraper is a bur which is formed at an arris, and turned at very nearly a right angle to the sur face of the scraper.

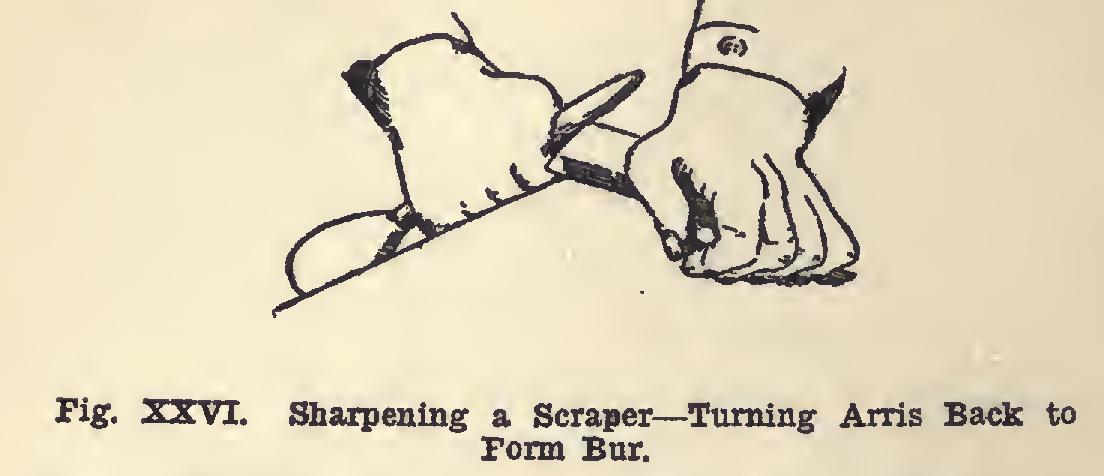

When a scraper becomes dull, each edge is draw-filed, so as to make it square and straight, with the corners slightly rounded. Sometimes the edges are rounded slightly from end to end to prevent digging. Frequently the scraper has its edges and surfaces ground square on an oil stone after the draw-filing, so that the arrises may be formed into smoother burs.

After filing, the scraper is laid flat on the bench, and the arrises forced over as in Fig. XXV. The tool used is called a burnisher; any smooth piece of steel would do. Next, turn these arrises back over the side of the scraper (Fig. XXVI). Great pressure is not necessary to form the burs properly.