Framing for Windows

frame, wood, rebated, water, glass, sash and shown

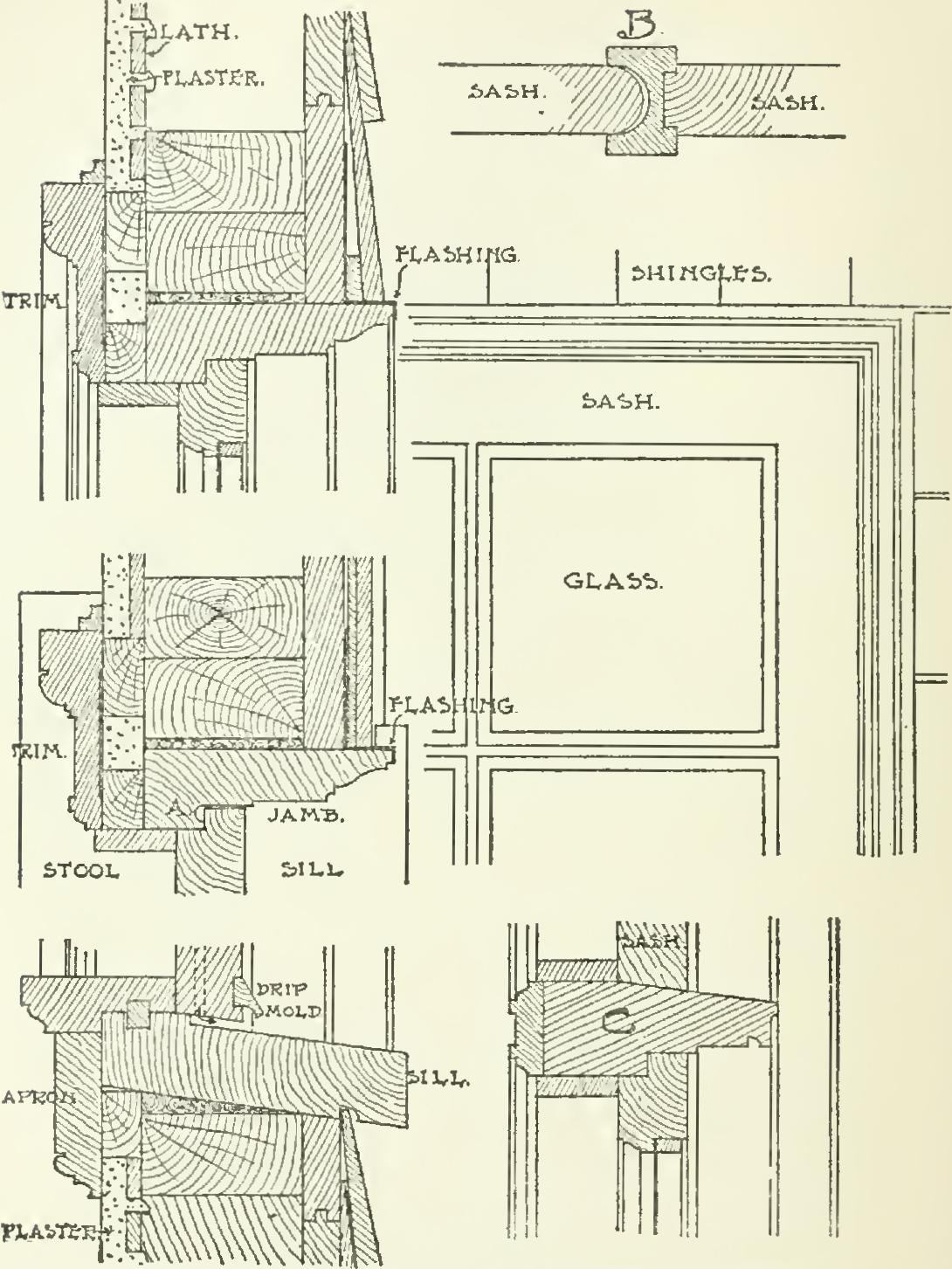

SAY ness of the plaster. Frequently a small mould is provided in the angle formed by the inter section of the back-band with the plaster; and in such cases the feathered edge is omitted, as the small wall mould is pliable enough to fit the uneven surface of the plaster. Grounds (G) are set about all openings to give a nailing for the trim. The plastering between the grounds and the window-frame should never be omitted, as it makes the window wind-proof.

In the central part of the figure is a hori zontal section taken through the jamb of the window, and shows it rebated the same as the head. The inside stop bead is hollowed at H to form a channel down which any water that may beat iu between sash and jamb will pass. The water passes out through a similar channel in the sill. The stop beads should be secured in place by means of round-head brass screws and countersunk brass sockets, which will per mit of adjusting the stop beads one way or the other by loosening the screw a little. These screws should, of course, be set equidistant.

Below is a vertical section taken through the sill of the window, which shows it rebated for sash and plowed for stool. Stool is moulded and should have returned ends. Bed mould and apron should also have returned ends. Sash is grooved on the under side for a drip. Glass should be bedded in putty, sprigged, and back-puttied. Where plate glass is used, wood beads should be used to hold the glass in position, and putty should be used as a bed for the glass.

Where it is desired to have sashes light in appearance—that is, using as little wood as possible—the stiles and rails are worked in cherry or other hardwood.

L

is a section showing the construction of the meeting stiles of casements opening in two leaves. The joint is rebated one-half inch, and edges are beaded as shown.

A somewhat better form of construction is shown at M, which shows the sashes rebated and beaded as above described, but with an addi tional groove at X which serves as a conductor for any water that may beat in at the joint, dis charging it on the sill outside of the sash.

N

is a section showing the construction of a transom bar. A water nose is formed on the projecting part of bar by cutting a hollow, as at W.

Another outward-opening casement window is illustrated in detail in Fig. 25, showing one of the best methods of making the frame and sashes, and incidentally showing how the out side architrave may be omitted, which feature is frequently considered desirable from the standpoint of appearance.

The frame wall is constructed in the usual manner of 2 by 4-inch studs, placed 16 inches on centers, and doubled for jambs, heads, and sills of openings. The studs are covered on the outside with matched sheathing boards, heavy building paper, and shingles. The inside of the wall is wood-lathed and plastered. Plaster, except the white finish, should be carried behind all wood base, wainscot, trim, dressers, etc.

Fig. 25. Framing for Outward-Opening Casements.

The frame is made from 2-inch stock, rebated and moulded as shown, and projects beyond the outside surface of the sheathing boards not less 340 than one and three-eighths inches, so that the shingles or other exterior wall covering may butt against it. This manner of allowing the frame to project to take the shingles, does away with the necessity for an outside architrave. This is considered a desirable feature when it is important that as little wood as possible shall show about the window. The head of the win dow is made water-tight by flashing with tin or copper in the manner shown. The flashing is carried up behind shingles at least 4 inches, and down over top of frame, so that the metal pro jects sufficiently to form a drip, which prevents water from trickling down under head of frame. In the better class of work the joints of the shingles with the jambs are also flashed in the manner shown.

After the frame is set, the spaces about the frame should be made weather-proof by calking with oakum and plastering over, or by filling up the interstices with plastering mortar.

The sashes are rebated, and are fitted with wood beads for holding the glass in place, in stead of using putty. The glass, however, is bedded in putty before the wood beads are af fixed. A drip moulding is let into the lower rail of sash to catch any water drippings and pre vent them from beating in under the sash.