Framing for Windows

sash, casement, strips, top, weather, screens, moulded and fitting

The trim is moulded and hollow-backed, and at the angles is put together with slip tongues or dowels, and mitered. A moulded back-band follows about same. It has an architrave head, and the fascia is plain and blocked at the top for the crown-moulding. This moulding may be cut out of one and one-eighth inch stock, or built up of several members. Crown-mouldings, except where they abut the ceiling, should be capped on top; otherwise they form a lodging place for dust and dirt.

The trim finishes on a stool with moulded edge. This stool, with its bed-moulds, corre sponds to the cap of the wainscot, which is shown skirting the room. Walls behind wain scots, base, trim, and other interior finishing woodwork, should be plastered to the floor, but the white coat may be omitted. The jamb and head linings are tongued into the frame.

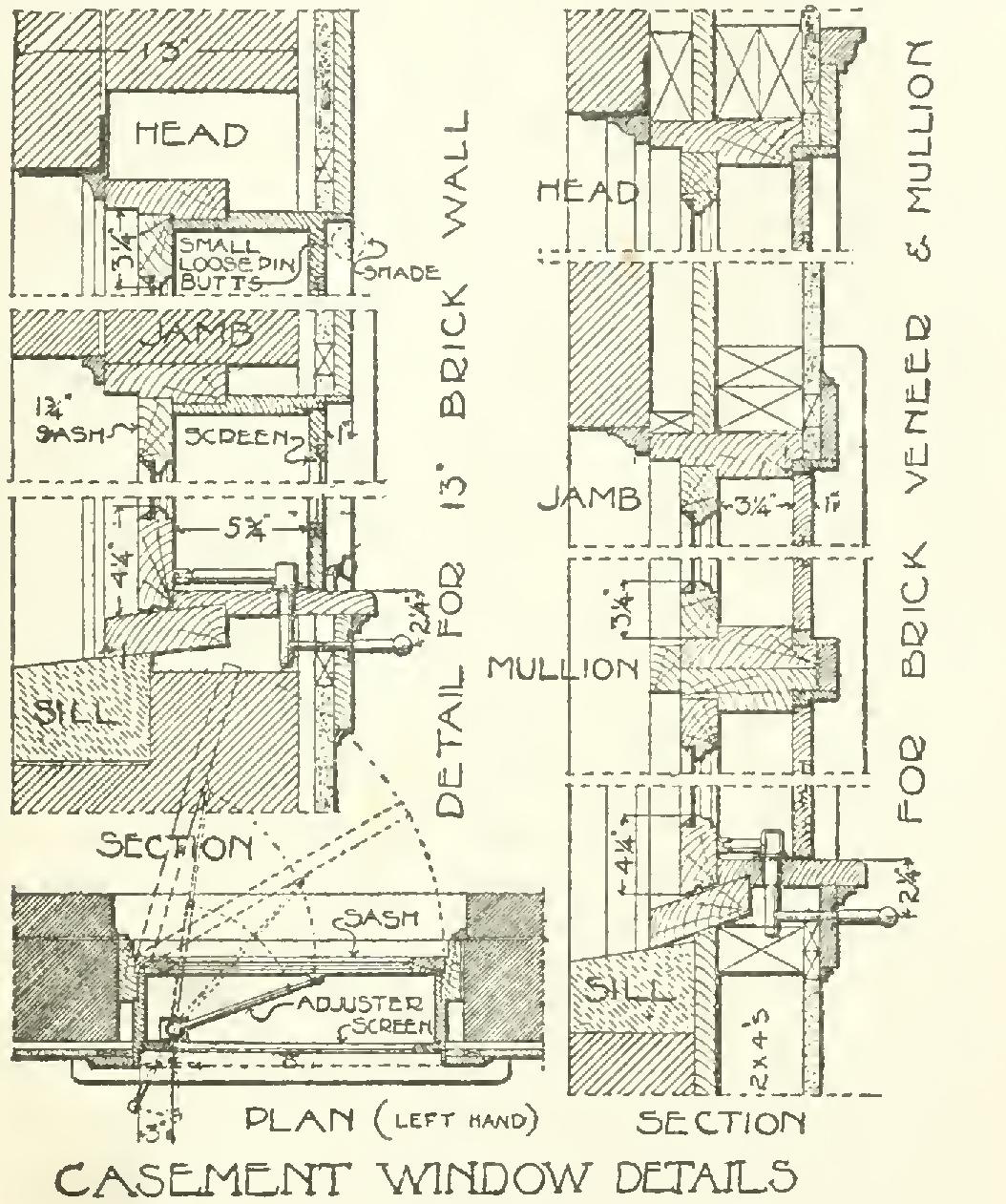

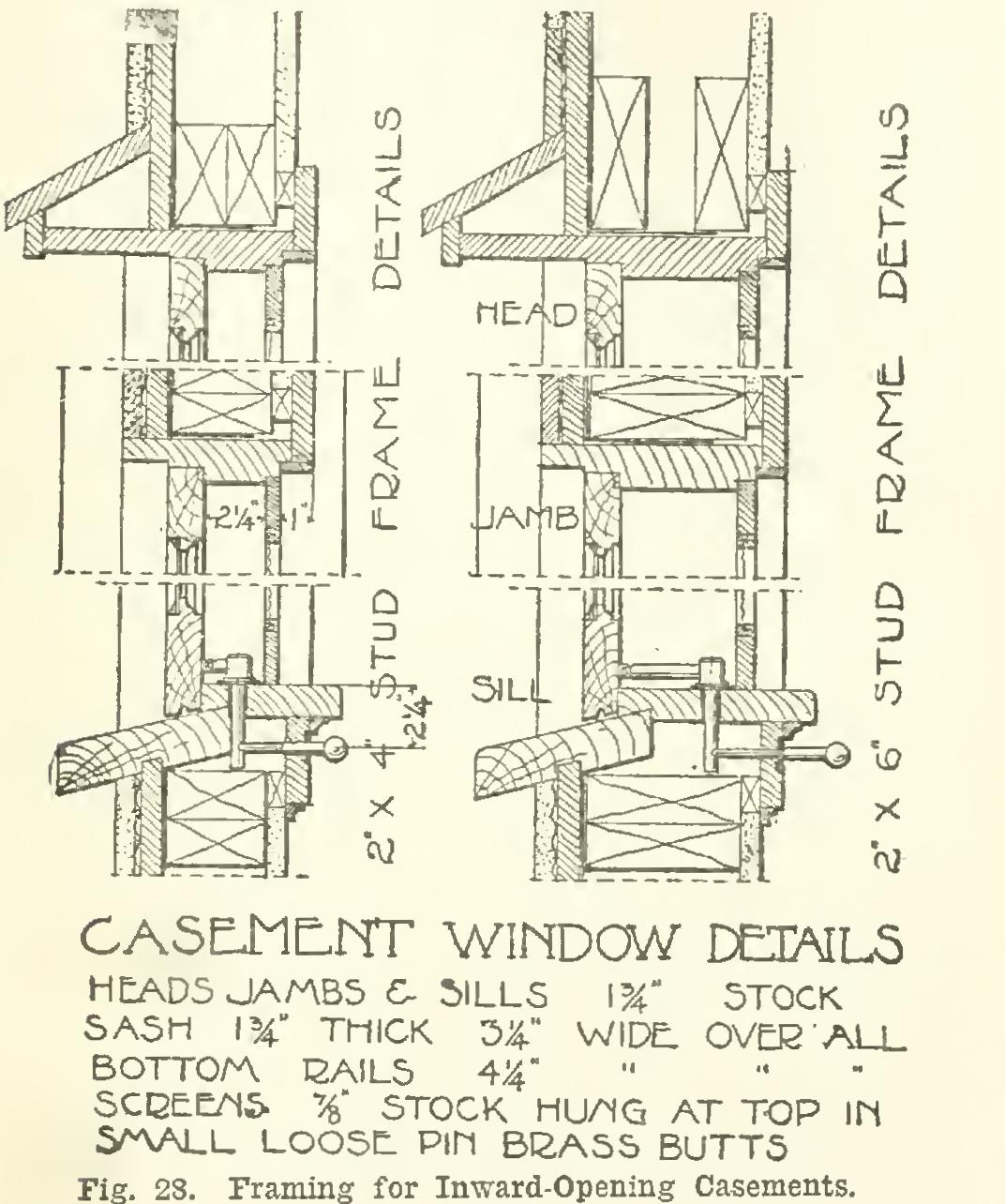

A simple inward-opening casement is illus trated in Figs. 27 and 28, adapted to the several types of wall construction, masonry, brick veneer, and stud frame.

Many architects think it necessary to rebate their casement sash. One carpenter who has employed this type of casement with all success for twelve years, has found in practice that rebating the sash simply weakens it and adds practically nothing to its tightness against weather. Rebated sash are objectionable be cause of the difficulty of fitting them accurately and the difficulty of refitting old sash which have, for any reason, ceased to fit properly through shrinkage, swelling, settlement, sag, or slight distortion of the sash.

Casement sash should be strongly made. For good work, sash should be inches thick, and the sides and top 3 inches wide exclusive of glass rebate; the bottom members should be 1 inch wider, and all made of clear white pine stock thoroughly tongued and pinned together, There is little danger that sash so made will ever sag. Large-sized butts should be Wised, Fig. 27. Framing for Inward-Opening Casements.

preferably 4 by 4, galvanized, with brass pins to insure their always working easily.

Except in the South and in California, case ment windows should be equipped with weather strips. If it can be afforded, some good form of metal weather strip should be used. Both interlocking and friction strips are sufficiently tight.

For the general run of residence work, how ever the ordinary cheap wood and felt strip answers the purpose very well, making case ments tighter than double-hung sash. Wooden

strips are not only cheap and easy of applica tion; but they never cause the sash to stick, as is often the case with metal strips if they are sufficiently weather-tight. When the felts are worn out, it costs little to put in new strips. For the better class of buildings, casement frames should be rebated out of solid stock.

Where each mullion assists in supporting the weight of the floor or wall above—in other words, where this weight is no entirely carried to the sides of a group of casement windows by means of a heavy lintel—at least one 2 by 4 stud should be inserted between the frames of each mullion. First-story casement windows, unless otherwise protected, should be provided with projecting hoods in order that they may be left slightly open for ventilation in warm, rainy weather. The same is true of second-story case ments in gables or elsewhere where not pro tected by the eaves.

The best method of fitting screens and storm sash to casements is to hinge them at the top, fitting them with a small bolt or catch to hold them in position at the bottom so that they will not be blown in by the wind. Thus fitted, they can be readily opened to give access to the hook or adjuster by which the sash is held open, with out interfering with curtains or shades.

The accompanying details all show sufficient space in the jamb-lining next to the screen for window-shade fittings, which are much neater so applied than on the face of the casing. They show the application of one of the new forms of casement adjuster which operates the sash through a locking plate secured to the apron, doing away with the necessity of opening the screens in order to open, close, or adjust the sash. Several devices which accomplish this have recently been placed on the market, and, although more expensive than the old-fashioned adjusters, they are well worth the extra cost, as to open the screen in order to operate the sash is always more or less of a nuisance. In fact, the bother of doing this has been one of the chief reasons why the building public in the United States has both loath to adopt casement windows, in most parts of the United States insect screens being a necessity. In England, where screens are seldom used and little needed, casements are the universal window.