Systems of Reinforcement

ceiling, beams, system, floor, column, placed and construction

The Mushroom System is so-called from the peculiar formation of the rods around the column head and from the remarkable rapidity with which it may be erected. The idea of this system is primarily to simplify the cen tering, and thus reduce the cost of the temporary part of the construction without skimping the materials in the finished work.

The arrangement of the reinforcement is designed with a view to securing the maximum efficiency of the materials through straining the concrete in a number of directions, the compression in one direction tending to balance and offset that in another; incidentally to con centrate the maximum amount of reinforcement around and over the support where the shear is the greatest ; to enable removal of the forms at the earliest possible period; and finally to eliminate beams and ribs which interfere with light and catch dust, cost money to plaster and finish, and reduce the clear story height. The flat ceiling so obtained gives free and unobstructed illumina tion from the windows; it permits one to place partitions anywhere without regard to the floor, giving an unusual stiffness and solidity due to the fact that a part of the material which in the beam type is placed in the ribs, is consolidated in the slab, making the slab of unusual thickness with an actual decrease in the total amount of material where the loads are at all heavy.

In

fighting a fire where the contents of the building are particularly inflammable, those who have given the matter attention will understand how a rib in the ceiling stops the stream of water which is elevated sufficiently to strike the ceiling, given a flat ceiling it is easy to reach any part of the floor desired, for, if the stream is elevated and strikes the ceiling, it merely glances along and is spread over the floor where required, instead of being stopped short where it strikes a pro jecting beam or rib.

The Mushroom System is adaptable to nearly all classes of buildings—court houses, state capitols, ware houses, factories, hotels, bridges, and high office buildings. In the office building partitions can be readily shifted to suit the tenant without interference of rib framing, while cost of plaster finish is but 65 per cent of that where beams are used; and for a given clear story height, there is a saving of 10 per cent of exterior walls.

In a factory building the advantages claimed for this system are : 1. Better distribution of light.

2. The flat ceiling enables more convenient placing of shafting than where ribs are used.

3. Freedom from vibration. Owing to the fact that any concentrated load brings into action the reinforce ment of the entire panel, it has little local effect, and consequently the construction is subjected to a minimum of vibration.

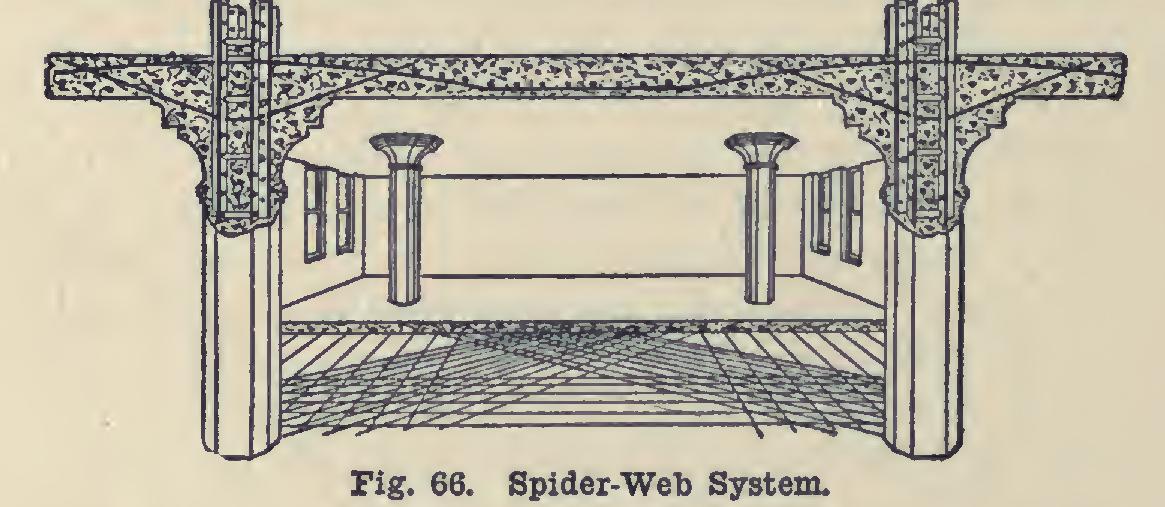

The Barton "Spider-Web" System of rein forcing floor slabs is shown in Plate 17, while the method of forming column caps is shown in Plate 18. The interesting features of this sys tem, including the special advantages claimed for it, are as follows: This construction has no beams or girders, thus per mitting the light to be diffused, unobstructed, over the entire ceiling, and, reflected, to penetrate the interiors of wide buildings; Permits sprinkler-heads to be economically spaced, which in some cases makes a saving of twenty-five per cent on the cost of equipment; Permits trolley beams to be placed flat against ceiling, instead of being hung on beams and hangers; Reduces the height of each story by the depth of beams used in beam and girder construction, which aver ages sixteen inches, aggregating twelve feet in the height of a nine-story building; hence the cost of construction and heating is reduced.

The steel core of the Barton column is formed of angles held in position by bolts and pipe separators, which are designed to carry the load placed on them. Where desired, spiral steel hooping may be placed on the outside of metal core.

The formation of the metal core permits the concrete in column to be rammed at all stages of the concrete pouring, as the core is unobstructed before the pouring of the concrete.

Metal centering plates are placed at the tops of column cores at floor levels, making it impossible for centers of columns to be otherwise than directly over one another, forming the steel in continuous columns from foundation to roof. In the case of rod columns, it is extremely difficult to place the rods over one another or make them continuous. This causes eccentric loading of columns, which accounts for many instances of collapse.