Hoppers and Hopper Bevels

piece, length, square, tongue, blade, corner and cut

HOPPERS AND HOPPER BEVELS In the laying out of many special types of buildings—such as farm buildings, or those in tended for industrial uses, as mills, factories, shops, etc.—there are many problems of a special character constantly arising that call for inge nuity on the part of the carpenter. They do not necessarily involve new principles, but the ap plication of familiar principles in new combi nations or under new conditions.

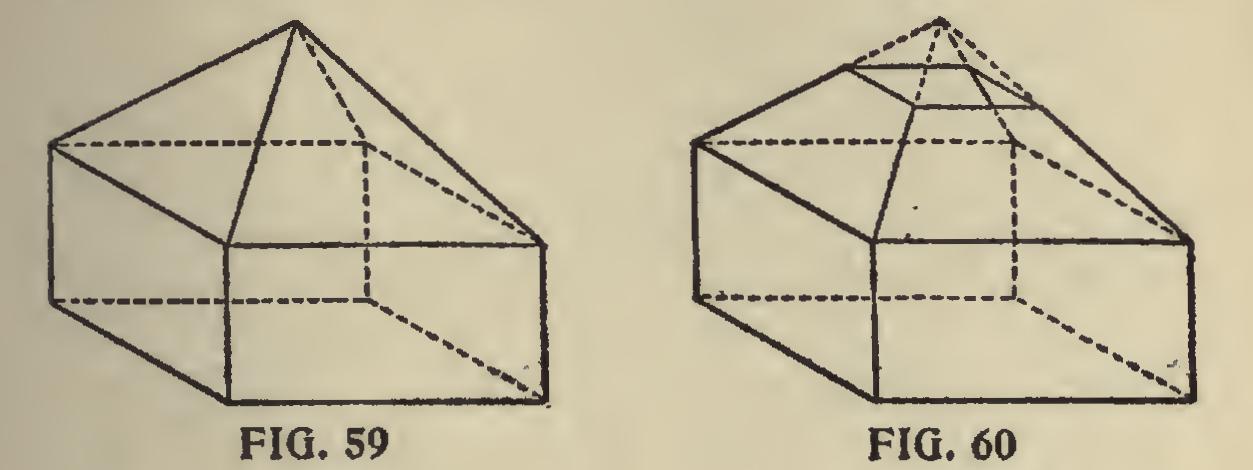

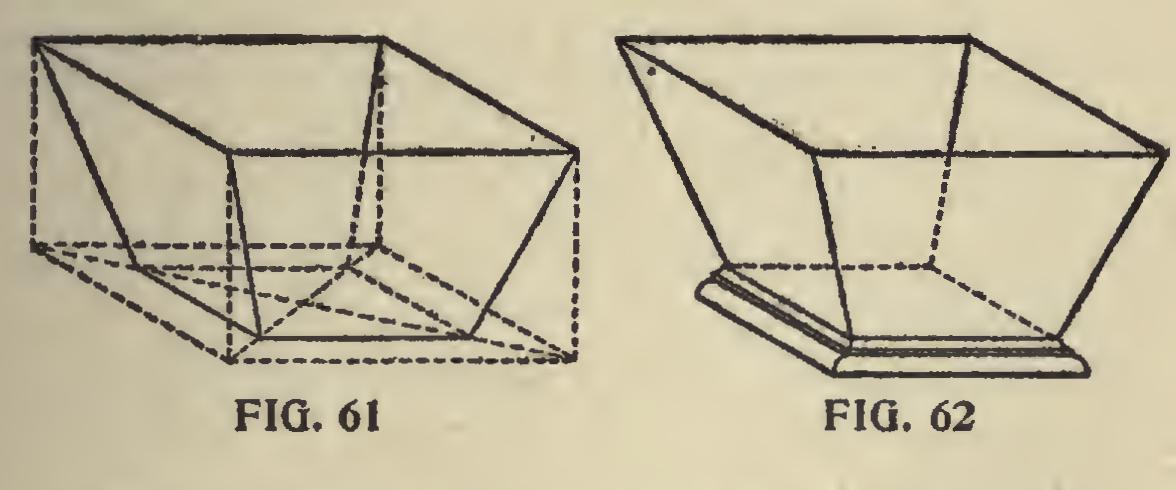

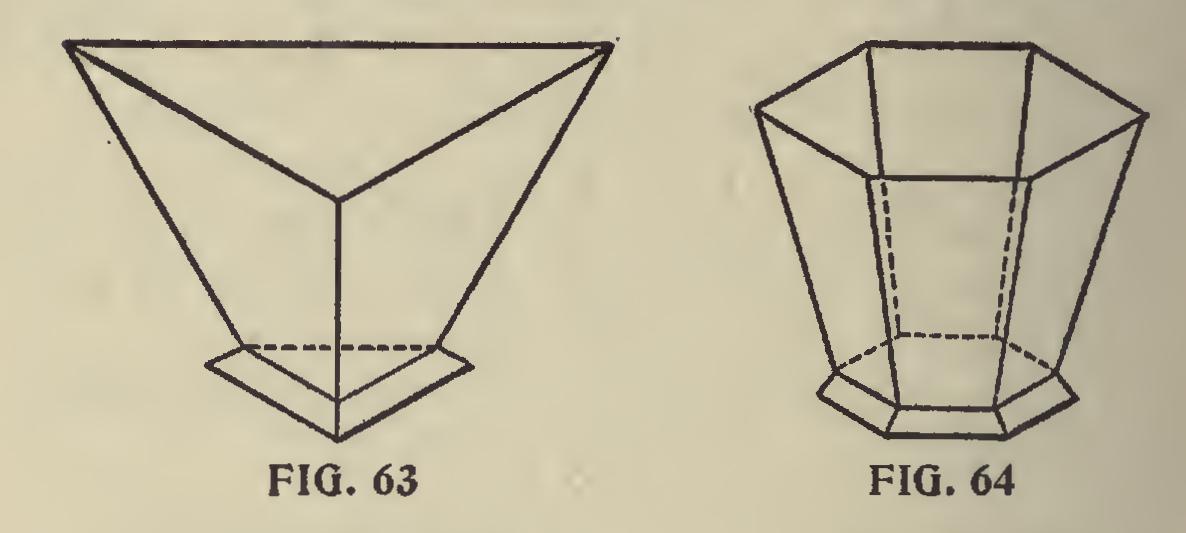

Laying Out Hopper Bevels with the Square. —The subject of hopper bevels is one that is not generally understood among workmen. We have known good mechanics who could frame com plicated hip and valley roofs, but when it came to laying out hopper bevels with the square, they were, so to speak, at sea. Yet the same principle involved in the framing of a hip-roof applies to a hopper—that is, a hip-roof inverted is a hopper. The roof boards that fit in the valley over the hip form the hopper joint. However, there are many ways of arriving at the cuts, and we will here present the views of various writers on the subject. Many have been published before, but we give them here because the progressive me chanic is not a "one way man," but wants to know the different ways of obtaining the same result, from which he can select the way that best suits his purpose. The following illustra 116 tions in Figs. 59 to 64 represent the various classes of hoppers.

Fig. 59 represents a cottage, the roof of which is an inverted hopper.

Fig. 60 represents the same, showing the roof part only, with the apex taken off, which may be the bottom of the hopper.

Fig. 61 represents the hopper in its natural position.

Fig. 62 represents a rectangular hopper with projecting bottom piece, and Figs. 63 and 64 represent the same for the triangular and hexag onal hoppers.

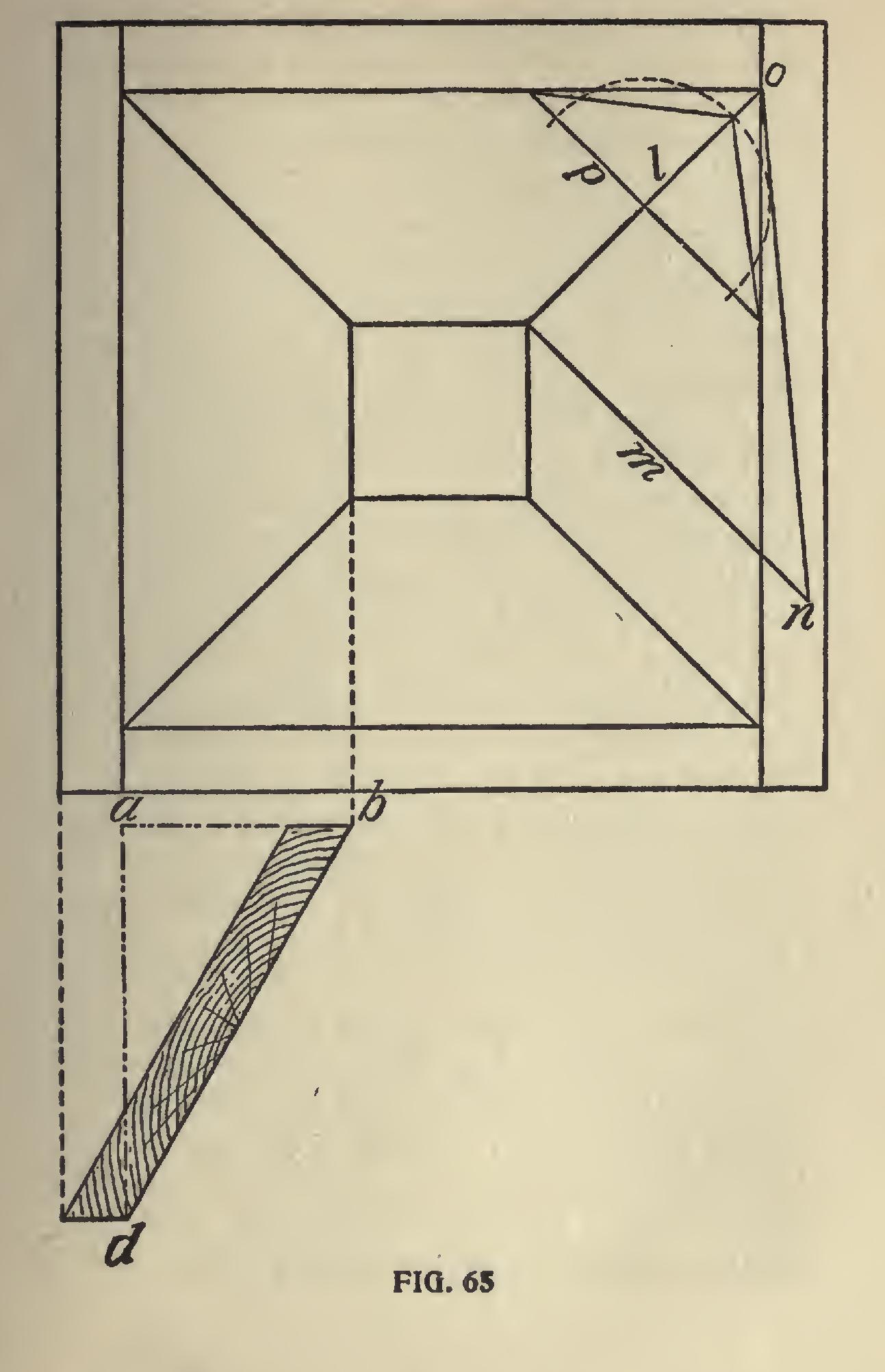

The following method of finding the bevels and width of sides and ends of a square hopper is from Mr. Connell.

In Fig. 65 the large square represents the upper edges of the hopper and the small one the lower edges or base. The width of the sides and ends is found in this way: Take the run ab on the tongue, and the perpendicular height ad on the blade. It is thus found in the same manner as the end of a brace. To find the cut for a butt

joint, take the width of side on blade and half the length of the base on tongue; the latter gives the cut. For a miter joint take width of side on the blade and perpendicular height on tongue; the latter gives the cut.

For the cut across the sides of the boards, take the run ab on the tongue, and the width of side on blade; the tongue gives the cut. In case of butt joints the inside corners of the sides and ends are longer than the outside, so if a hopper is to be of a certain size, the lengths of ends and sides are to be measured on the inside edge of each piece, and the bevels struck across the edges to these marks. Of course if the hop per is to be square, the thickness of the sides must be taken from the ends.

If the top and bottom edges are to be hori zontal, the bevel is thus found: Take the per pendicular height of hoppers on the blade and the run on the tongue, the latter gives the miter cut, in other words it is the 45 degree angle.