Stair Building

tread, riser, edge, string, risers, groove, treads, shown and line

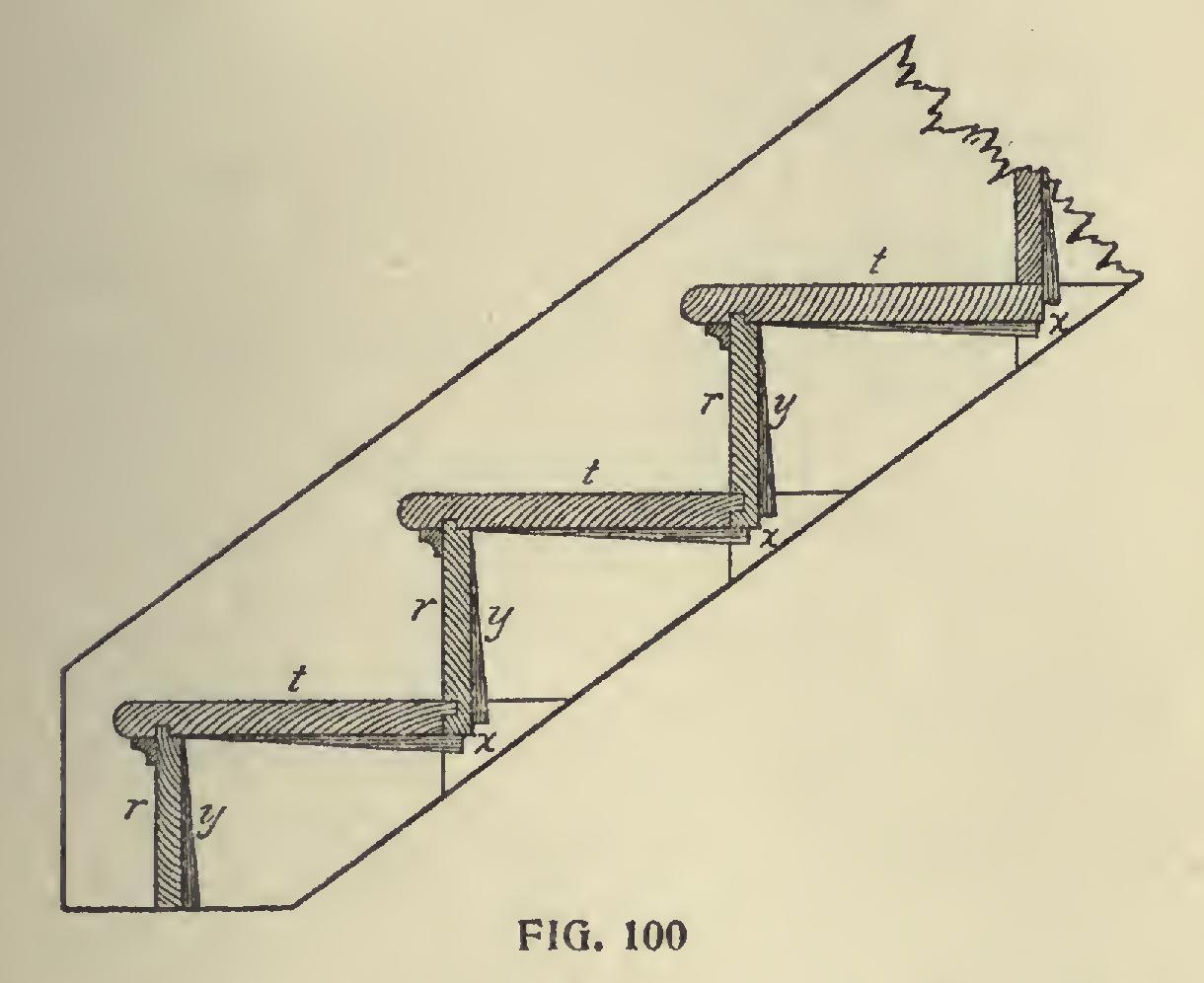

Open Strings.—Fig. 96 shows a portion of the stairs in position. S, S, shows the strings, which in this case are cut square; that is, the part of the string to which the riser is joined is cut square across, and the "butt" or end wood of the riser is seen. In this case, also, the end of the tread is cut square off and flush with the string and riser. Both strings in this instance are open strings.

Usually in stairs of this kind, the ends of the treads are rounded off similar to the front of the tread, and the ends project over the strings the same distance that the front edge projects over the riser. If a moulding or "cove" is used under the nosing in front, it should be carried round on the string to the back edge of the tread, and cut off square, for in this case the back edge of the tread will be square. The riser is shown at R, and it will be noticed that it runs down behind the tread on the back edge, and is either nailed or screwed to the tread.

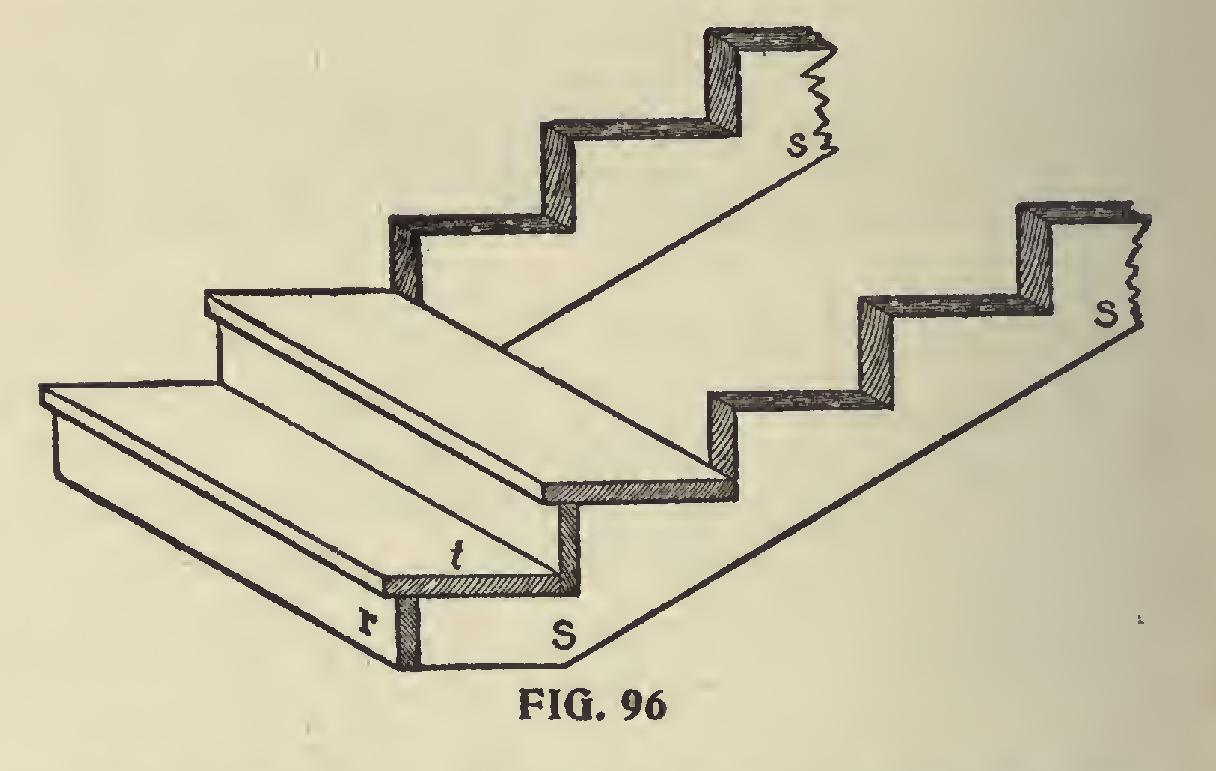

Risers and Treads.—Fig. 97 shows the cus tomary way of putting risers and treads together.

T, T shows the treads, R, R the risers, S, S the string; 0, 0 the cove moulding under the nosing X, X. B, B shows the blocks that hold the tread and risers together. These blocks should be from four to six inches long, and made of very dry wood. Their section may be from one to two inches square. On a tread three feet long, three of these blocks should be used at about equal distances apart, putting the two outside ones about six inches from the strings. They are glued in the angle.

It will be noticed that the riser has a lip on the upper edge, which enters into a groove in the tread. This lip is generally about *, inches long, and may be or z of an inch in thickness. Care must be taken in getting out the risers, that they are not made too narrow, as allowance must be made for the lip. If the riser is a little too wide it will do no harm, as the overwidth may hang down below the tread; but it must be made the exact width where it rests on the string.

The treads must be made the exact width required before they are grooved or the nosing worked on the outer edge. The lip or tongue on the riser should fit snug in the groove and bottom. By following these last instructions, and seeing that the blocks are well glued in, a good solid job will be the result.

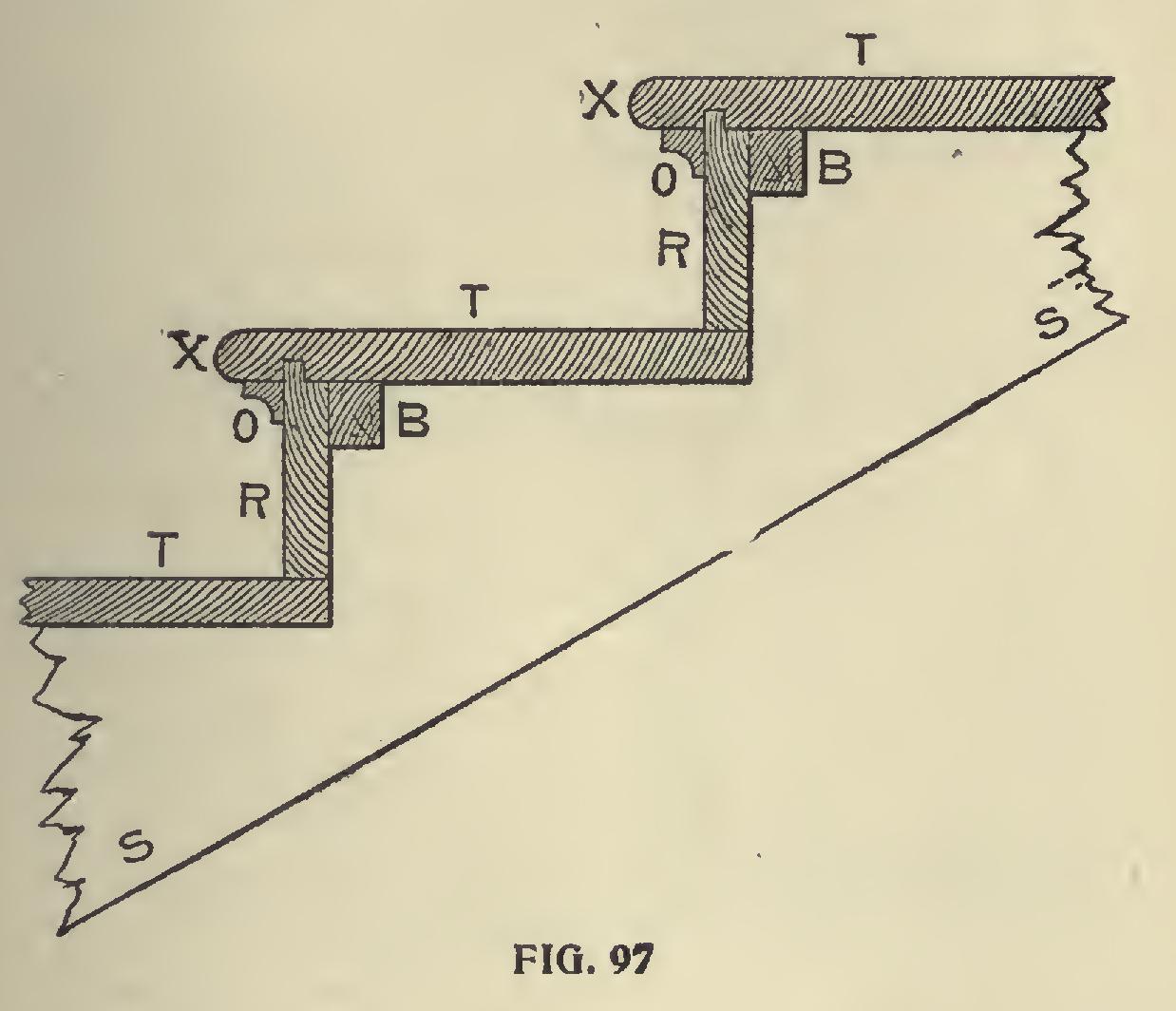

In Fig. 98 a scheme for the construction of the tread and riser is shown. The tread has a lip worked on it at the back edge, which enters a groove ploughed in the riser. The riser also has a lip left on the upper edge, which goes into a groove made in the tread similar to the method shown in Fig. 97.

The cove is shown at b, and the angle block is also represented. This makes a very solid step when well put together, and, where the steps are to be of the better kind, this method of construct ing the step may be adopted with advantage.

This method is a favorite one with stair builders, and has proved to be a substantial one, thoUgh it costs a little more than the ordinary method.

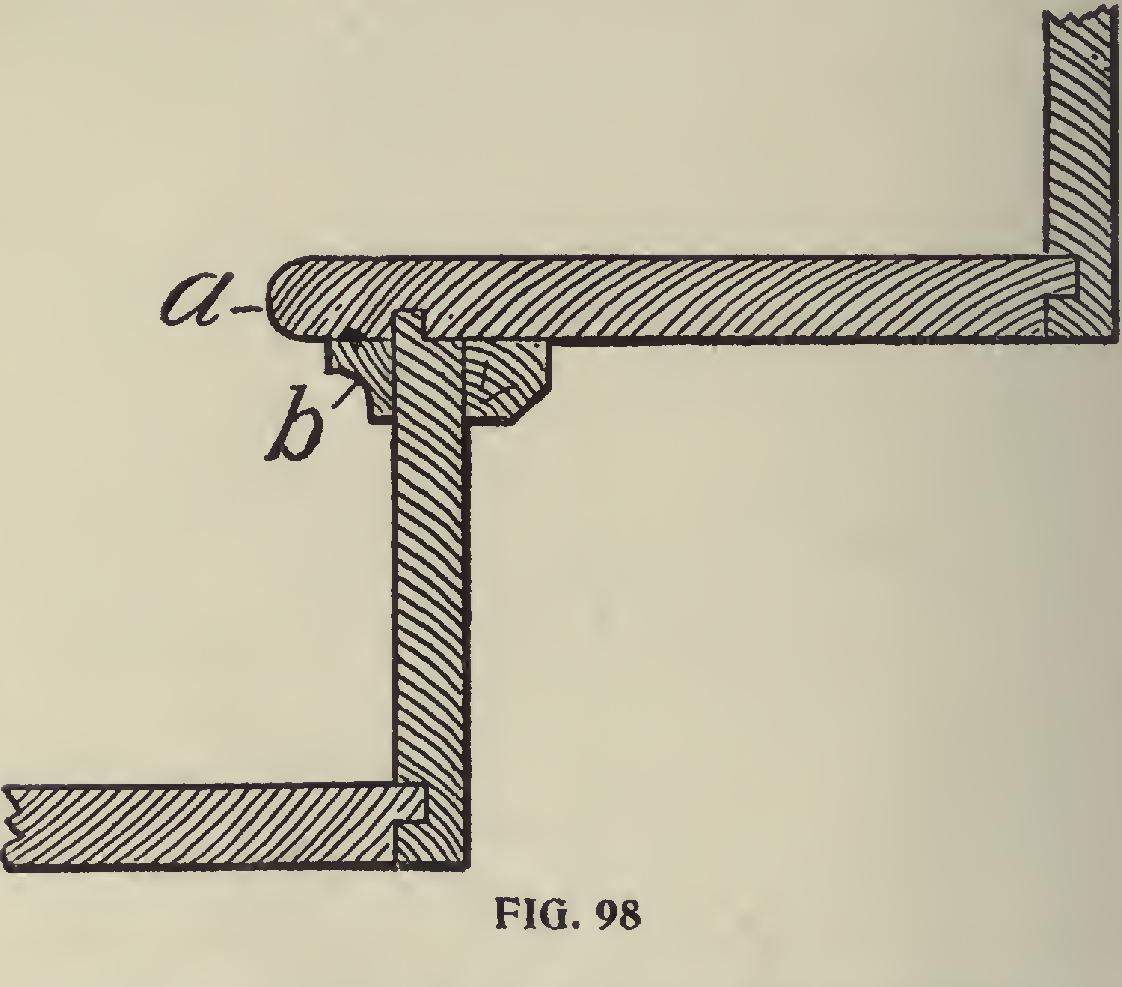

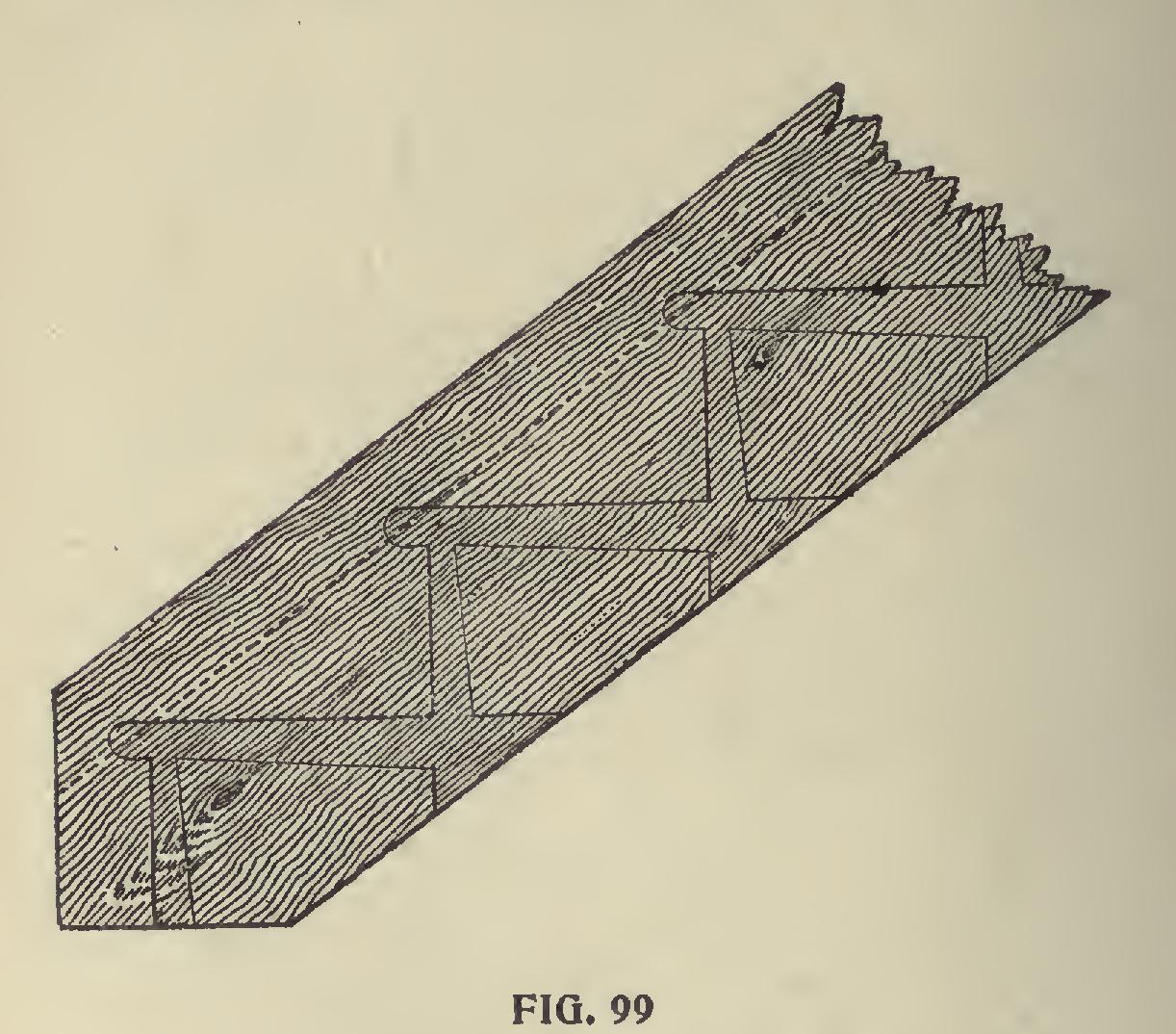

Housed or Closed Strings.—Fig. 99 represents a housed or closed string. In this the risers and treads are let into the strings from the back side.

Gauge lightly a line from the upper edge of the string, the distance intended to stand above the treads as shown in the dotted line. On this line apply the pitch-board, as explained on pre vious pages. In laying out housed strings, it is as well to take the fence off the pitch-board, as it can be handled better without it, as the long side will have to be kept close to the gauge line, to insure good work. The top lines for treads and the face lines for risers, are the lines that de fine the step, and cannot be changed; but the back line of the riser and the lower line of the tread should be made to run so that the housing or groove will be wider at the under side of the string than at the junction of the riser and tread at the nosing, where the grooves will be the same width as the riser and tread are in thickness separately. The nosing projects over the riser, as will be seen, and to mark this portion out, it is usual to make a template or pattern for the purpose. Indeed, it is best to make a template to lay out the whole housing of the tread, and in shape as the shaded part shown in the illustration.

The reason the grooves are left wider at the back edge of tread is so that a wedge can be driven between the tread and the lower edge of the groove, to force the top side of the tread close to the upper edge of the groove, thus making a tight joint and insuring strength and rigidity to the whole struct ure. The risers are also wedged into place, as is shown in Fig. 100. After the treads and risers are laid out on the string, a sharp pointed knife blade should be used to mark the lines for the face of the riser and top of the tread, then a fine tenon saw should be used to saw down to the exact depth. This will not be difficult to perform when the hole forming the nosing recess has been bored to the proper depth. A gauge line should be made on the back edge of the string to indicate the depth of the housing. Care should be taken in removing the wood from the grooves, that too much is not taken or the grooves made too deep, A gauge for trying the depth may be made out of a piece of hard wood, say about four inches long and three inches wide, by about one-half inch in thickness. Make a tenon on the center of one end, about three-quarters of an inch in width, and cut the shoulders back sufficiently to admit the tenon being long enough to touch the bottom of the groove or housing, when the shoulders rest on the face of the string.