Roughing-In

pipe, fig, vent, tee, waste, stack and top

In some cases, a slip-joint nut (Fig. 22) is used.

Fig. 23 shows a type of vent tee that is ex tensively employed. This can be obtained with both ends intended for connection to iron pipe, instead of the form shown, which is for lead waste and iron vent pipes. The part that re ceives the pipe from the trap has a long, threaded shank, which can be cut off to suit the job it is being used on; and this is a very good feature. See Fig. 23.

We shall now rough-in the stack for the first floor lavatory. We first calk-in a Y with clean out, as we did on the sink stack, and continue to basement ceiling, where we may have, as before, to use an offset to get back into the partition. At the proper height, we place a tapped tee, inches, with a nipple in the opening which will extend l/2-inch through the plaster. This will allow the use of a slip-joint nut (Fig. 22) when we come to set up the lavatory.

In the top of this tee, we calk a reducing coupling, and extend up to a point just below the roof with iron pipe. At this point we screw on a coupling to calk into a 2x4-inch increaser, and use a short piece of 4-inch soil pipe to extend through the roof, with necessary roof-flashing.

This manner of roughing-in is termed con tinuous venting. It is preferable to venting on the sink and wash trays, since, with this style, there is not the chance for the vent pipe to choke up, which is apt to occur with the sink style of venting.

The vent work on this job will be done with black iron pipe and cast-iron fittings. Gal vanized pipe and fittings are sometimes used; sometimes black pipe and galvanized fittings; and sometimes again, galvanized pipe and black cast-iron fittings. In some cases, black pipe coated inside with asphaltum and having re cessed drainage fittings are used. In any case, provision should be made for cleaning the vent pipes at times when needed. When a vent is taken from the top or crown of a trap, grease will accumulate in the vent pipe, and in time will choke it up entirely; and this is where "con tinuous" venting has the advantage.

The question as to what kind of material shall enter into the roughing-in of the job will be largely governed by local rulings where there is an Inspector, and the work will require in spection and testing before being covered up.

Whether an inspection is necessary or not, all work should be tested before being covered up, and this will be taken up later on and fully described.

We shall now proceed to rough-in the stack for the bathroom. We first calk-in a cleanout plug into a Y, the same as for the other two stacks, and then continue up to the bathroom. Here we shall require a sanitary tee with a 2-inch opening in the side to receive the bath waste. W e run a 4x2-inch Y in the side opening of the tee, for the lavatory waste. Continuing over to the partition, and extending upwards, we insert two tapped tees for the bath and lava tory vents, and then continue up to a point just below the roof, where we enlarge the pipe to 5 inches and extend through the roof, with the necessary roof-flashing.

All the soil-pipe in the stacks may be "Extra Heavy" and the vents "Standard" pipe; or all may be "Standard." The specifications usually cover this point.

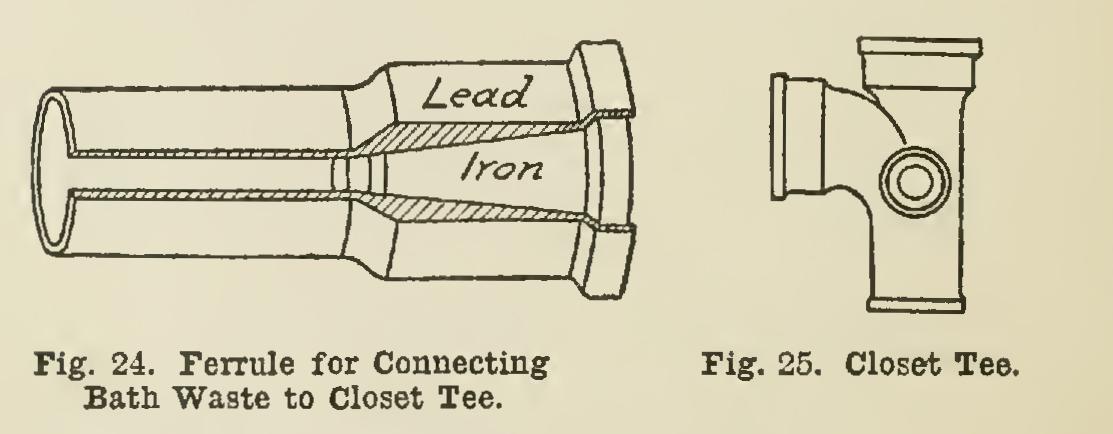

In the top of the 4-inch sanitary tee, we calk a combination lead ferrule, as shown in Fig. 24, and this will receive the discharge from the water-closet. Fig. 20 shows the stack elevation for the first-floor lavatory.

Fig. 21 shows the stack elevation for the bathroom. Ordinarily the closet opening would be in the side of the 4-inch sanitary tee; but in this case the opening will be in the top, owing to the fact that the first-floor partition is not directly under the bathroom partition, and re quires an offsetting of the pipe-work between the ceiling and the floor. In the side opening of the closet tee, we shall connect the bath waste, which will require a 2-inch ferrule like that shown in Fig. 24 or in Fig. 26, some lead waste-pipe, a 4x8-inch drum trap (Fig. 27) for the waste-pipe, a short piece of lead pipe, and a brass solder nipple (Fig. 28). The waste from the tub will branch into the drum trap at a point near the bottom; and the outlet to the soil-pipe will be taken out at a point near the top, but just below the vent branch.