Roughing-In

fig, pipe, lead, brass, shown, iron and ferrule

The wiping on the bath waste can be done before setting the same in place, with the excep tion of the joint where the solder nipple (Fig. 28) screws onto the vent-pipe already roughed in, and this can be wiped after the work is set in place. The screw top on the bath trap makes it easily accessible for cleaning purposes.

In the side opening of the 4x2-inch Y which is to rim into the closet tee, we shall place a lead ferrule (Fig. 24), which will require a wiped joint to connect it to the lead vent- and waste-pipe which is already roughed-in.

Fig. 25 shows the closet tee used on this in stallation, and less the side opening, this is the fitting ordinarily used.

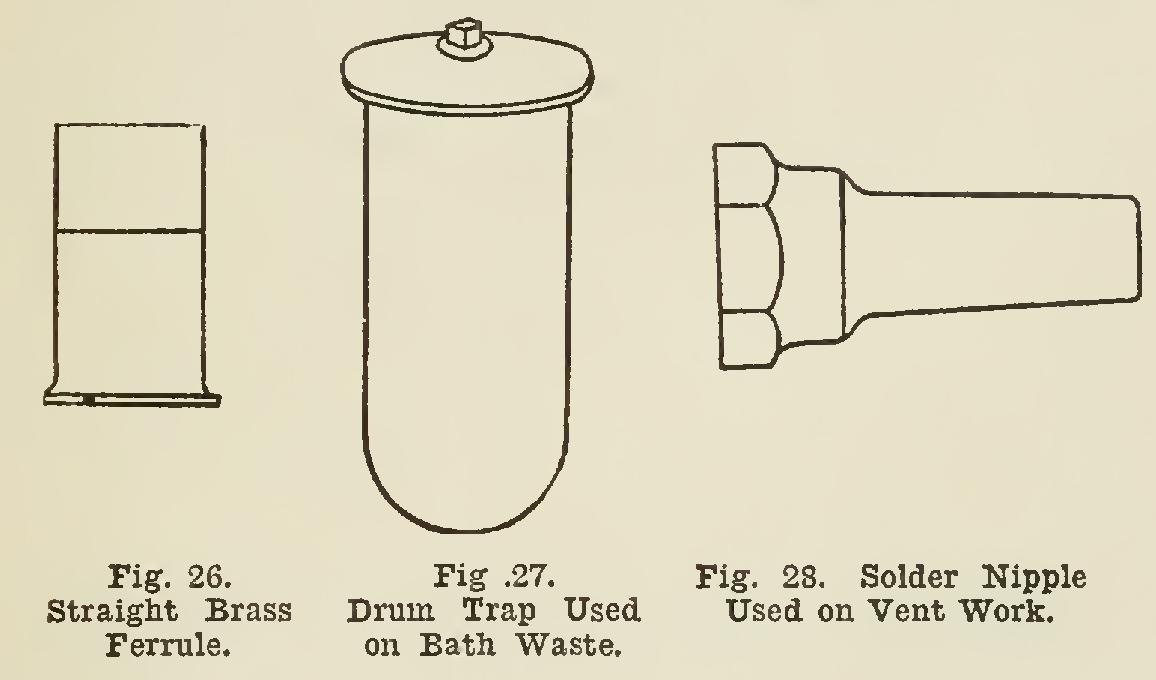

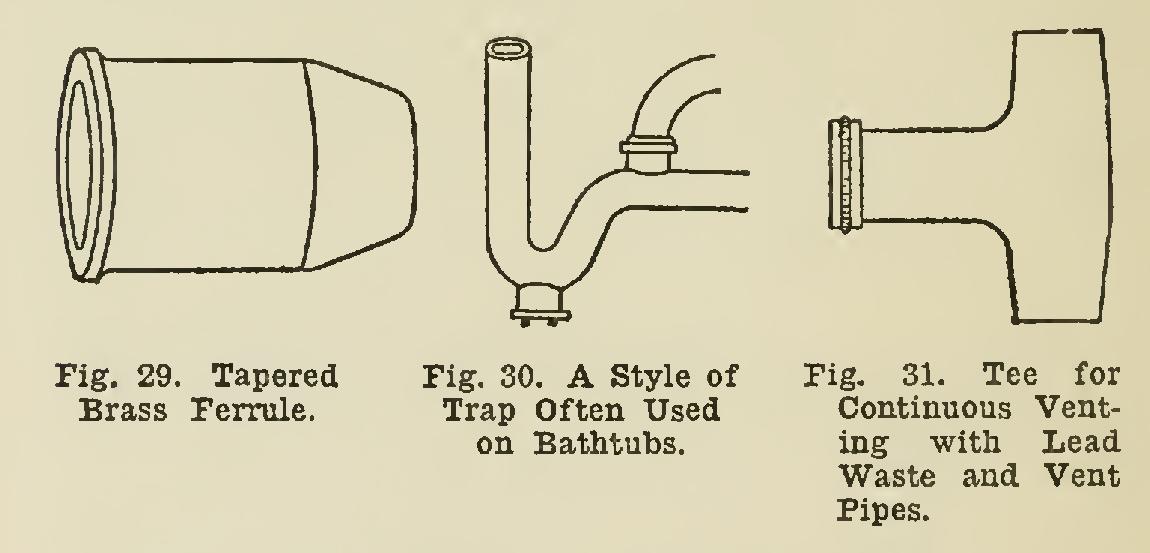

Fig. 26 shows a straight brass ferrule; and Fig. 29 shows a tapered brass ferrule, reducing down to the size of the waste-pipe used.

Fig. 28 shows the solder nipple used on the vent work, and this is made with either male or female threading.

Fig. 27 shows the drum trap used on the bath waste. The top, being a trifle larger than the body of the trap, will cover up the hole in the floor, and make a neat finish.

Fig. 30 shows another style of trap that is used extensively on bathtubs.

Fig. 31 shows another form of tee that can be used for the continuous style of venting where lead is used for both waste and vent pipes.

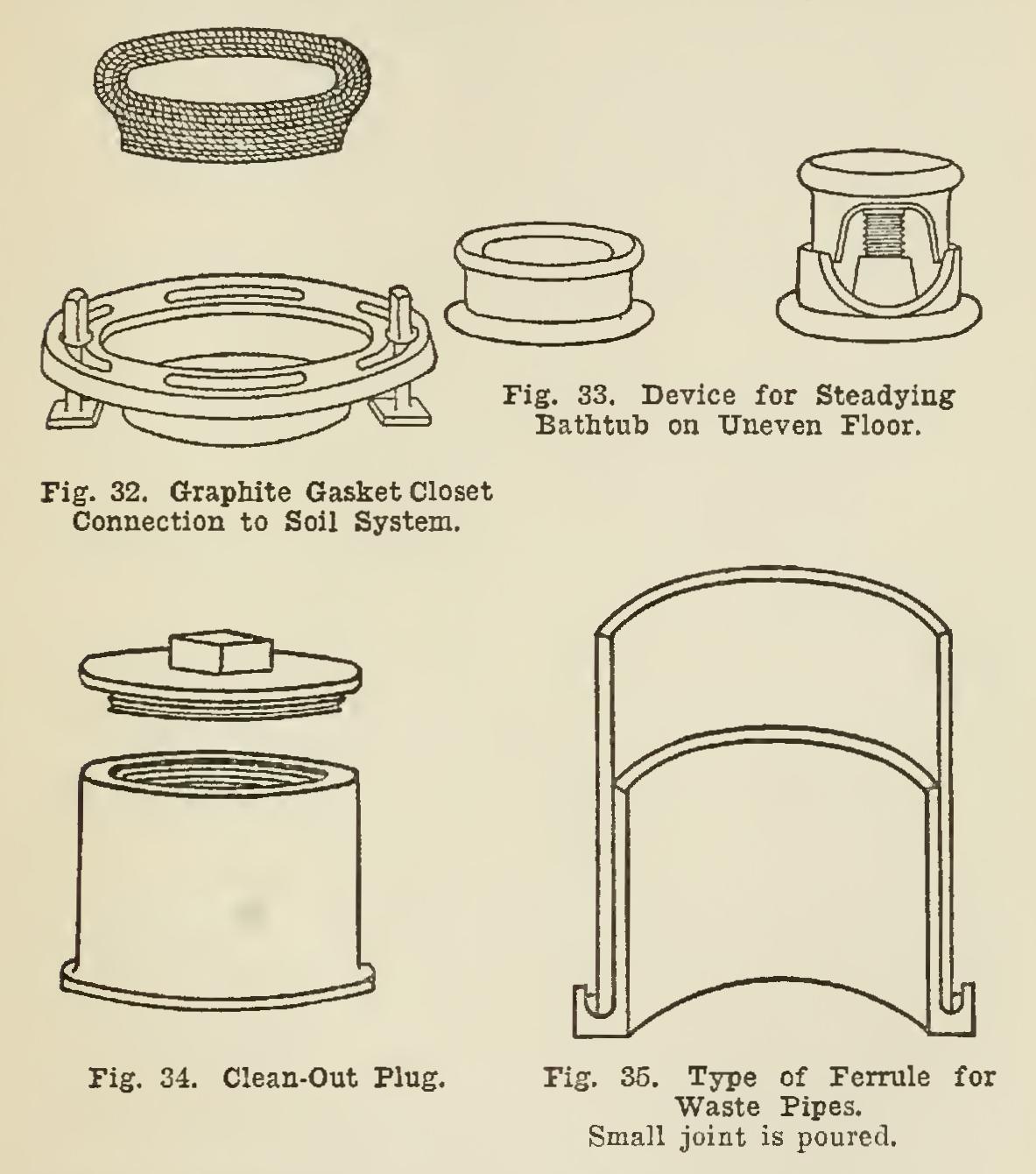

Fig. 32 shows a new method of joining the closet to the soil system, to be used instead of the putty joint that has commonly been used. This makes a very sanitary job, and insures a tight joint at this connection, which is by no means certain when putty is used. The brass flange is slipped over the 4-inch lead pipe ex tending through the floor for the closet connec tion; and then the pipe is sawed off at the proper distance to allow it to be flanged over into the brass floor-flange and then soldered. The graph ite gasket is next placed in position, and the closet is ready to be screwed in place.

In many instances, when you come to set your tub, you will find that the tub will not sit evenly, but has a rocking motion due to the un evenness of the floor. The device shown in Fig. 33 will be found very useful to remedy this trouble, and is inexpensive.

Fig. 34 shows the clean out plug which is placed at the foot of the different stacks for cleaning purposes. This has an iron body, and a brass screw; the latter is easily removed should occasion require it.

Fig. 35 shows another type of ferrule for waste-pipes. It is used by inserting the ferrule into the lead pipe, and pouring the small joint as shown.

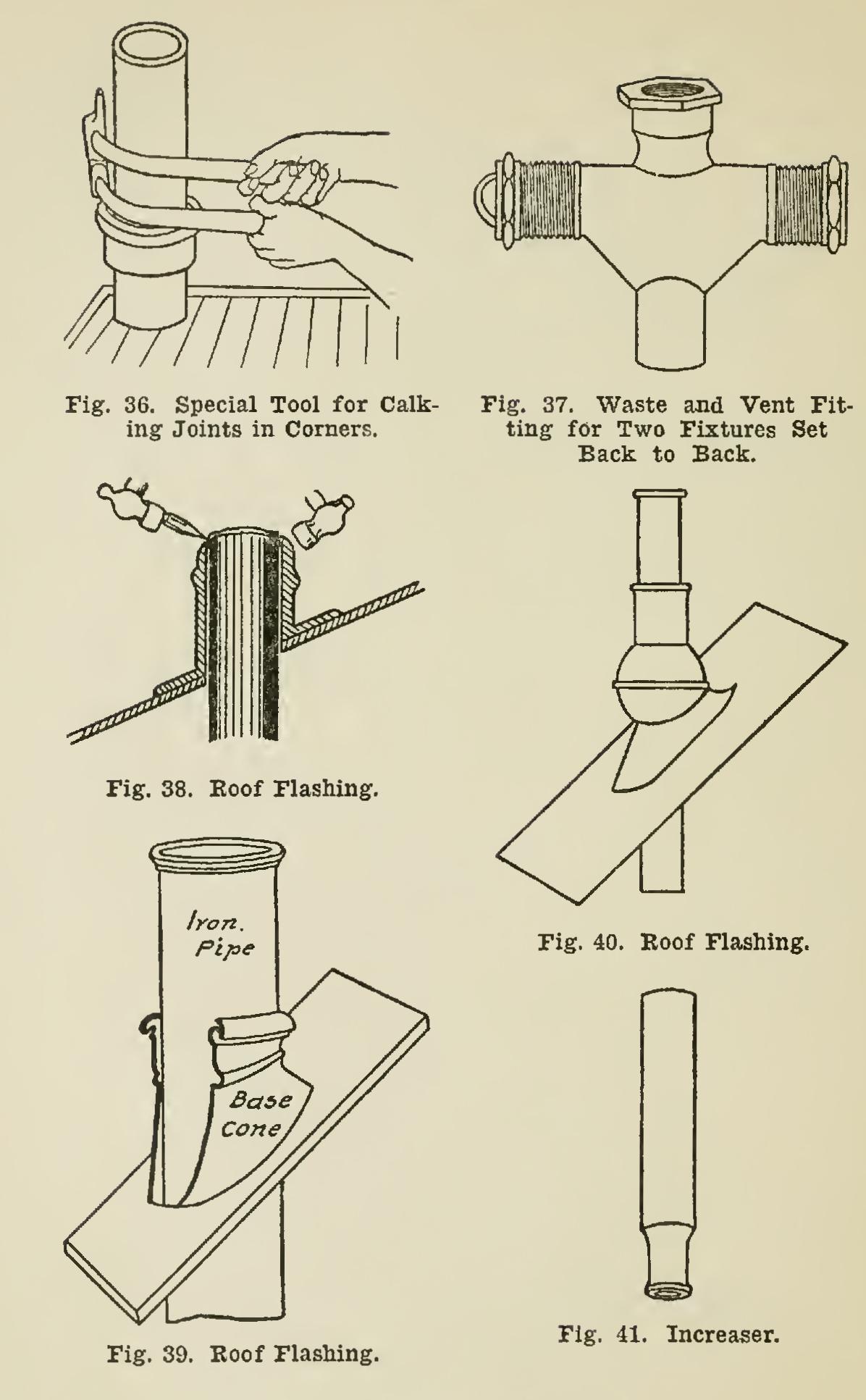

There will be times when soil-pipe joints will be encountered in corners where it will be a hard matter to get at them to calk them properly with the ordinary tools. In this case, some of the tools shown in Fig. 36 will be found very useful.

Fig. 37 shows a waste and vent fitting that can be used where two fixtures are set back to back.

Figs. 38, 39, and 40, show various styles of roof-flashings.

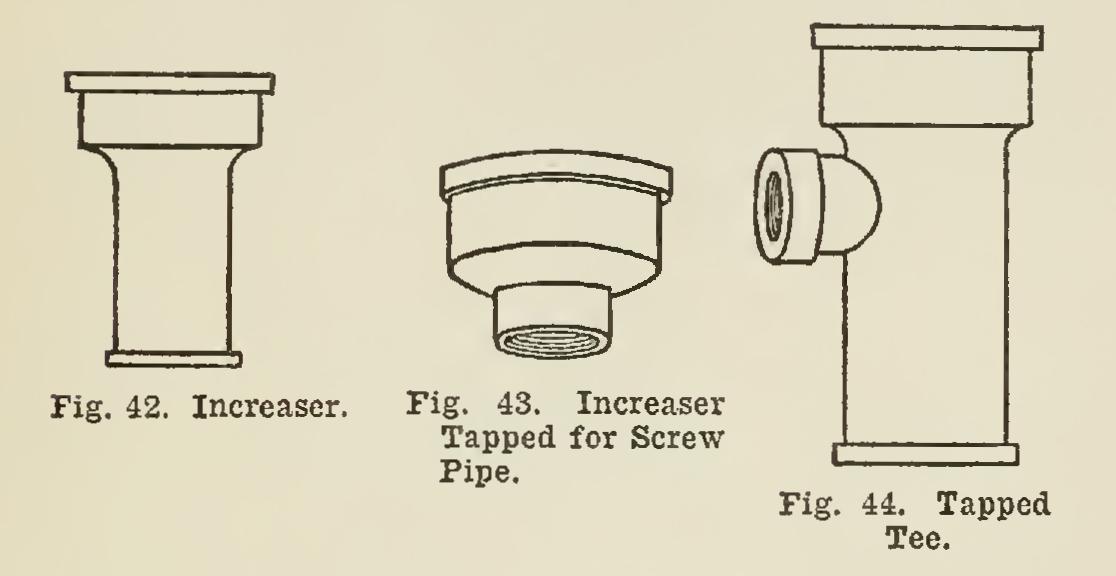

Figs. 41 and 42 show various styles of in creasers, which are used at a point just below the roof. They can be obtained either to calk-in as shown, or with the bottom end tapped for iron pipe to screw in. An increaser tapped for screw pipe is shown in Fig. 43.

Fig. 44 shows one style of tapped tee.

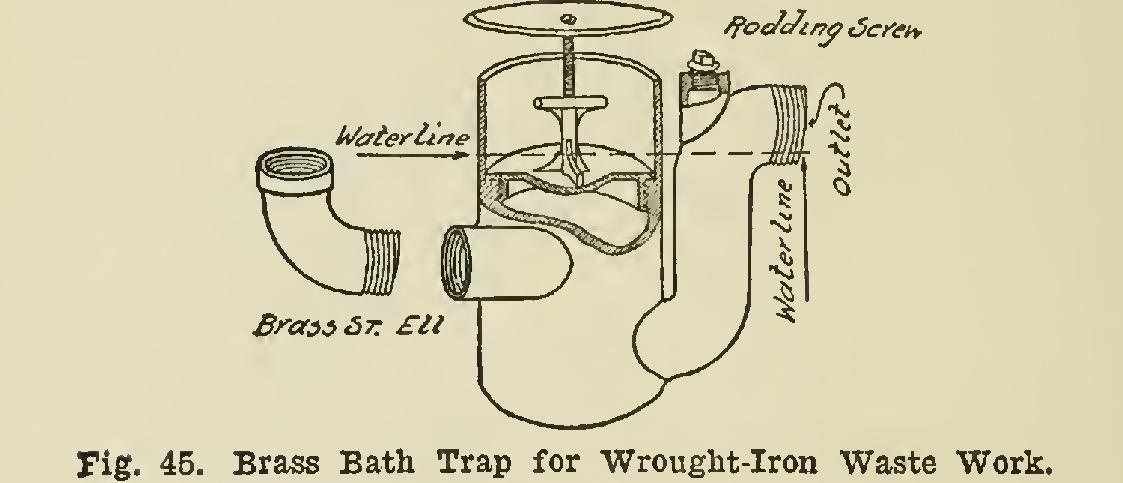

Fig. 45 shows a brass bath trap that is used where the waste work is all wrought iron—or, as it is sometimes called, the "Durham" system.

Water-Service Pipes. We shall now take up the water supplies to the various fixtures.

The main in the street is usually tapped by the local Water Company, and either the con necting pipe is run to the curb line by the Com pany, or else the plumber takes it at the point of connection. The kind of piping is governed by local rulings. In some sections of the country it is customary to run lead pipe to the curb, and then either lead or iron on into the building. Other places require only a short section of lead pipe at the main, usually about 18 inches in length; and from this point on into the building the pipe may be iron.

In any case, iron pipe should never be con nected directly to the corporation cock, as the cock that is screwed into the water main is termed, on account of the rigid connection being liable to breakage from settling either of the main or of the earth over the service. For a similar reason the service into the building should never be laid in the same ditch with the sewer line, unless a shelf of earth is left along side the sewer ditch, on which the water service can be laid, and which will insure a good foun dation for it. Many a plumber has had to dig up the service after it has been in but a short time, to repair a leak in it caused through set tling of the dirt.