Steam Heating

return, sizes, connection, system, boiler, wet and pipe

Where the elbow is placed on the end of the dry return for the drop connection into return opening of boiler, an automatic air-vent should be used, and this point should not be less than 14 inches above the water-line of the boiler, as previously described.

All branches are taken from the main with a 45-degree connection as shown in Fig. 18, and they should always pitch upward from the main at least one-half inch in each five inches of length. When supplying large radiators, the branches, as a rule, should be one size larger than the riser or radiator connection which they feed.

Tt is well to make connections to radiators in such a manner as will permit of some expansion of the riser. A swing joint at base of riser is sometimes employed for this purpose (see Fig. 24). When the length of a building is so great as to prevent the use of a dry return throughout the entire distance, it may be found imprac ticable to extend the main the full length of the building; and in such cases an extension of the main is made in the manner shown in Fig. 25, the size of the extension being governed by the square feet of radiation fed by it. Should it be required to supply only a few small radiators, it may drain back into the main in the same man ner as any other branch connection. As a rule, however, it shows better practice to drip the end of this extension into a wet return, as illustrated.

In this connection we again call attention to the fact that the risers out of the boiler should be two sizes larger than the horizontal pipes which they feed.

One-Pipe System with Wet Returns.

The one-pipe system of steam heating with wet re turns does not differ materially from any one of the methods previously described so far as the manner of running the mains and connecting the branches is concerned. There are some heat ing men who favor a wet-return system, believ ing that the provision of the wet return steadies the working of the system or "balances" the job. This system is specially adapted to jobs where the mains are exceptionally long or when surroundings make it necessary to work un usually close to the water-line of the boiler.

A wet return would be started on a circuit job as soon as the last branch or radiator had been connected, but the drop should not be made directly at the last connection. The main should

be extended not less than two feet beyond this point, where a reducing elbow tapped for an air valve should be placed on the end, and the drop then made into a wet return. This return, as a rule, is carried along the cellar wall to a point where a connection with the boiler can be con veniently made.

One method of installing a wet-return system NOTE.—The maximum amount of radiation given for any size of pipe is based upon favorable existing conditions, such as a short main (under 100 feet) and a compact job. When mains are extremely long and the amount of radiation scattered, the larger size of pipe should invariably be used.

When direct-indirect or indirect radiation is placed, the sizes as given above should be increased on this basis: 25 per cent for direct-indirect, and 50 per cent for indirect.

The pipe sizes in the above table are applicable for use with either the single-circuit or the divided-circuit system.

is to bleed all risers, as illustrated in Fig. 26. If the job is of such a character that the risers can be treated in this manner, much smaller piping may be employed than is ordinarily necessary with one-pipe work, as no condensation enters the main from radiators or branches, and its entire area is free space for the conveyance of live steam. Also, where risers are dripped into the return in the manner illustrated, it makes no difference in the results attained whether a 45-degree or a 90-degree connection is used in starting the branch from main.

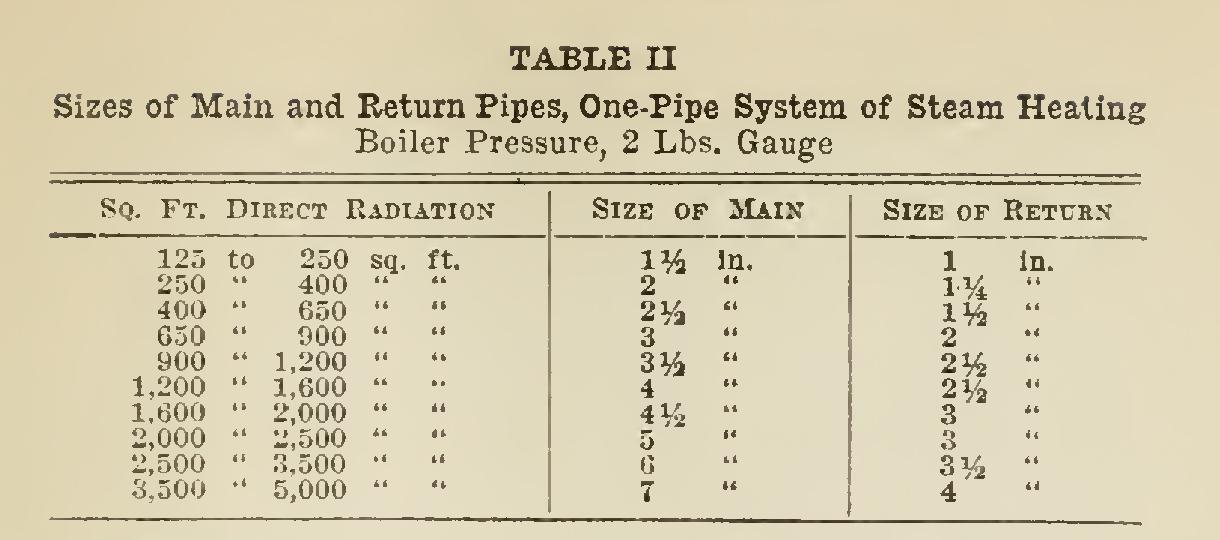

Sizes of Main and Return Pipes. Table II, giving pipe sizes for main flow pipes and returns, is based on a gauge pressure of 2 lbs. at the boiler. While some engineers consider the sizes as given somewhat excessive, the fitter can make 1 no mistake by adopting them on heating work. Perhaps circumstances surrounding installations in some particular instances might warrant ma terial reductions in the stated pipe sizes; but unless the fitter is fully conversant with the effect these conditions exert on the plant, it is better to be guided entirely by the sizes given, which have been proven by conclusive tests as worthy of general adoption.