Blinds Fittings for Doors

lock, locks, knobs, knob, latch, brass and bronze

The distance between the center of knob and front plate of lock should be about 3 inches.

The latch and bolt in a good lock should be heavy, and preferably of brass or bronze. The bevel on the latch should be of such a shape that, as the door closes, the latch will be easily de pressed by the strike without binding or catch ing. The usual form is that of a smooth curve beginning at the lock front and extending to the outer point or end of the latch.

Although most locks and latches come with the beveled latch-bolt in reversible form so that they can be used on either an in-opening or out opening door, it is better to specify at the start just which form is desired. For doors opening inward, the bevel of the latch bolt is spoken of as "regular." For doors opening outward, it is called a reverse bevel bolt. This condition should be noted in connection with the hand of a door when taking a list of the latches and locks needed in a house. The strike for a mortise lock may be the same for either case, but it is not so always and therefore should be noted. For rim locks, the two strikes are quite different.

Many locks are reversible for use on both right- and left-hand doors; but ordinarily a lock is either right-hand or left-hand, and should be specified as such in each instance. Reversible types of locks are not built as strongly in most instances as the straight type.

Keys. Keys vary from the cheap cast-iron type, which should be avoided, to the high-grade flat or corrugated nickel-bronze key with gold plated bow. Malleable iron, steel, bronze, and brass are all used, and all good. When a series of locks of a certain type are to be used in a building, it is convenient to have them master keyed, each lock still having its individual pass key. This often saves trouble and expense in case of a lost key. The drawback in such a sys tem is the possible loss of the master-key, which would mean replacing all locks concerned in order to insure safety.

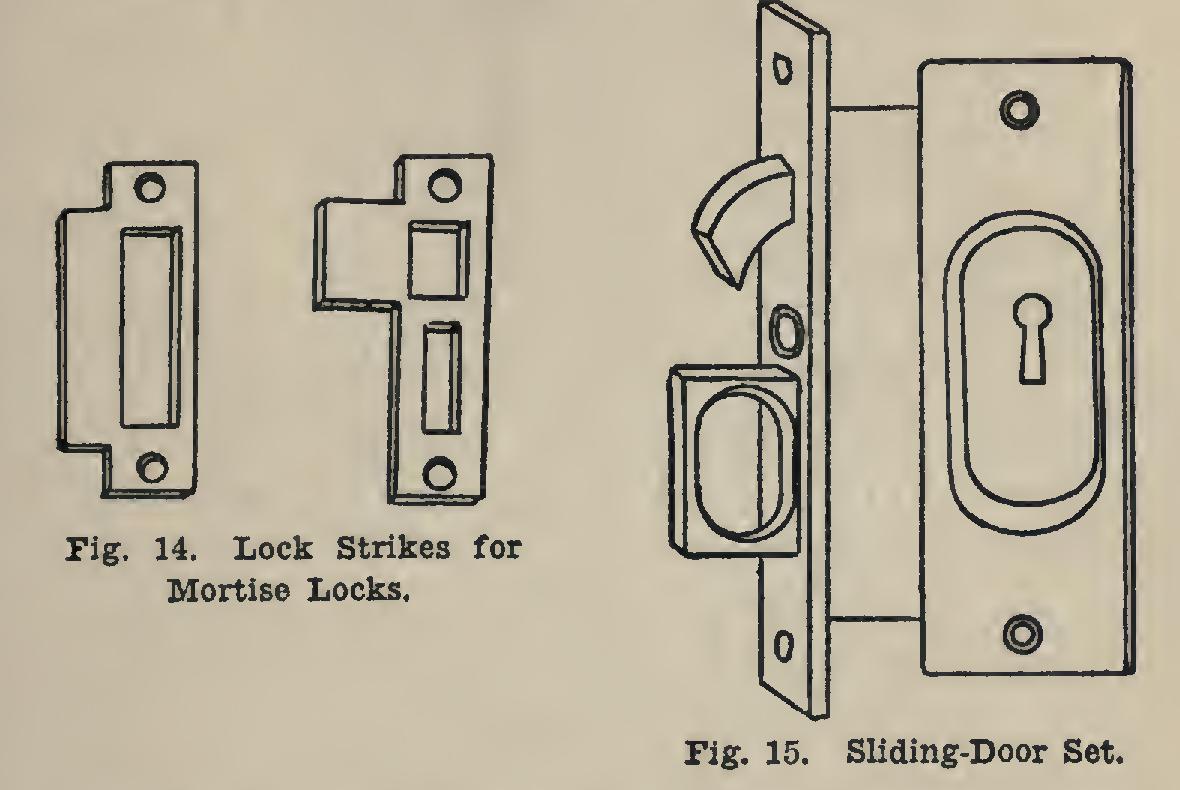

Fig. 7 shows a common form of lock strike for rim locks and latches; while Fig. 14 shows two types used for mortised locks. The strike for a rim lock is screwed direct to the casing to line up with the lock on the door stile; while, for a mortise lock, the strike is set into the side of the casing. Ordinarily there is a projecting

lip which guides the latch into its proper hole and prevents wear upon the woodwork.

Fig. 15 shows a common type of sliding-door set. This shows the lock bolt and also the disappearing pull.

A sliding-door latch without the lock is also on the market. This is worked by a lever fit ting into the space allowed for the flush pull.

In choosing the trim for locks and latches, care should be taken that the general appear ance of the knobs and escutcheons corresponds with that of the doors on which they are to be used. While plain types are greatly to be rec ommended for ordinary work, outside or en trance doors will often permit of the use of some simple design on knob and escutcheon which adds to the general effect.

Knobs are made of a variety of materials— wood, iron, cast brass, cast bronze, glass, pot tery, spun brass, etc. The best grades of knobs are cast from brass or bronze, and are generally about of an inch in thickness.

A close competitor to the cast knob is a com posite knob made by spinning a thin shell of brass or bronze over an interior shell of wrought steel. This makes a good serviceable knob with the strength and appearance of the cast knobs. Often the steel shell is omitted, the spun casing of brass or bronze being used alone. A knob of this type is liable to become indented from blows, thereby presenting a poor appearance.

Cast-iron knobs are used with the cheaper grades of locks, and are usually of some orna mental design. While they are generally serv iceable, their use is not recommended on good work. Wood knobs are but little used, except in the cheaper classes of work.

Pottery knobs are divided into three common classes: Porcelain, the ordinary white knob in general use; mineral, a brown-colored knob; and jet, which is of a deep black color. These are used on cheap grades of hardware and will ordi narily stand but little service. The shanks to such knobs are made of cast-iron or steel. Glass knobs have glass tops with metal shanks, but are expensive when a good quality are used. For ordinary cases, knobs should not be more than 7 inches in circumference.