Blinds Fittings for Doors

blind, shutter, leaf, fig, closed and hinge

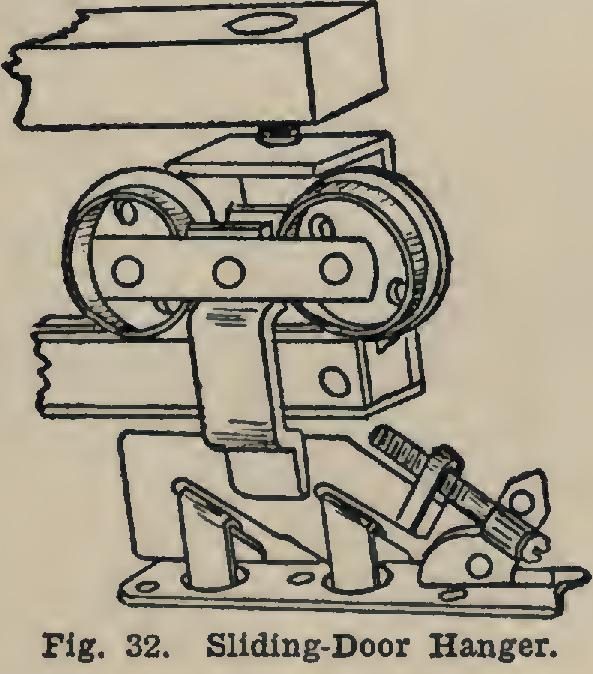

Sliding doors may be moved either by the old method of rollers or sheaves fastened to the bot tom part of doors and running on a light steel rail sunk in the floor, or by the use of overhead hangers as shown in Fig. 32. These hangers run on an overhead track supported in a special recess over the door. The track on which the rollers run is made of steel covered with strips of wood to make the action noiseless. Ball-bear ing journals are also used for this same purpose. The fitting of sliding doors should be left to mechanics practiced in this particular line of work, as an ill-fitting sliding door is a source of constant trouble.

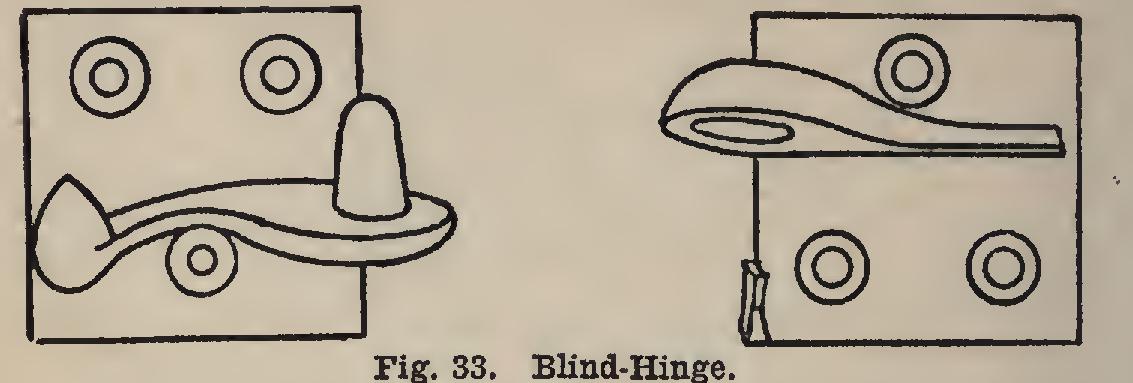

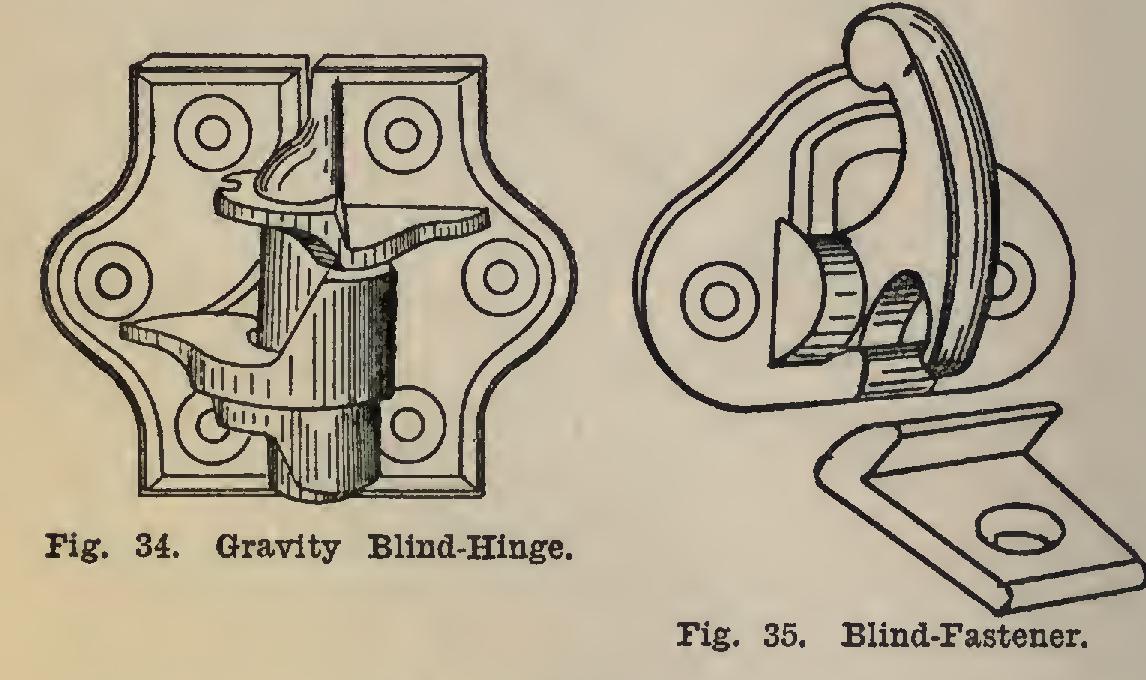

The hardware for blinds is of a simpler na ture than that just described for doors, and is comprised mainly of butts, fasteners, and ad justers. The butts used for blinds are either of a type which permits the blind to be hung from its side like a door, or to be swung outward at the bottom like an awning. Figs. 33 and 34 show two types of cast-iron blind-hinges which are commonly used. These are very unsatisfactory on account of their liability of failure in high winds or when subjected to slamming action. A wrought-iron or wrought-steel hinge is to be pre ferred, and can be easily obtained at practically the same price. The hinges shown in the figures are to be located on the side of the blind. The awning hinge referred to is 'not considered suit able for use on any but light narrow blinds. Fig. 34 is known as a gravity hinge.

Fig. 35 shows a fastener used to secure blinds in place when closed. The upper part is to be fastened to the blind, and the lower to the sill. The fasteners commonly used to hold the blind back against the wall with the old style of wrought-iron hinge, consisted of a revolving leaf on the end of a pin. The pin was driven into the woodwork of the wall, and the leaf turned up over the edge of the blind. Other devices, such

as flat springs along the bottom edge of the blind which catch over a notch on the end of a project ing wall-pin and are released by depressing the spring, are also used when necessary.

Various types of blind adjusters are on the market. The object of such appliances is to hold the blinds firmly in one of a given number of positions. They may be swung nearly open or held firmly closed as desired. The principle involved in one form is the location of the end of a rod, one end of which is pivoted to the blind, and the other is bent over so as to be inserted in any one of a number of holes in a metal piece which is screwed to the sill near the center of the window. Another small fitting on the inside face of the blind is located in such a manner that the bent end of the rod may pass through a lug on the fitting, and then into the piece on the sill, thus holding the blind firmly closed.

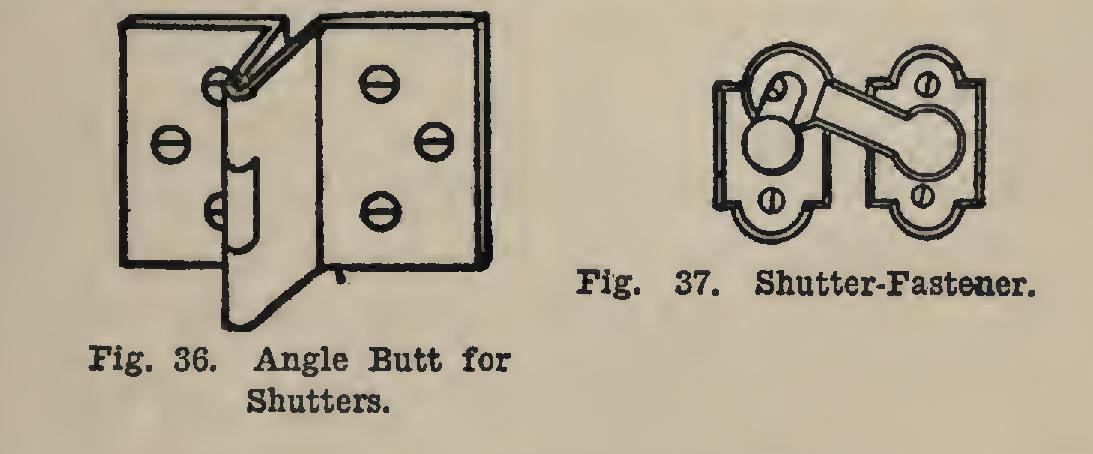

For shutters or inside blinds, the forms of butts or hinges vary from the ordinary butt up to the so-called shutter flaps. Fig. 36 shows a form of angle butt which is used when a shutter has three folds. The purpose of the construction of this butt is to allow the folds to take such a position when open that they may fold together compactly into the window frame.

A form of light bar for holding shutters closed is shown in Fig. 37. One half of the fit ting is attached to a leaf on one side of the shut ter, while the other half, or pin, is attached to a leaf on the other half of the shutter. On three leaf shutters, it is advisable to use a form of flush shutter bar, unless proper space is left when the shutter is folded.

A great variety of shutter knobs are avail able; but as such knobs are quite prominent, they should be substantial and of good design.