Blinds Fittings for Doors

bolt, door, shown, fig, spring, bolts and desired

A lighter form of bolt used more commonly in cabinet work is shown in Fig. 23. This is known as a flush bolt.

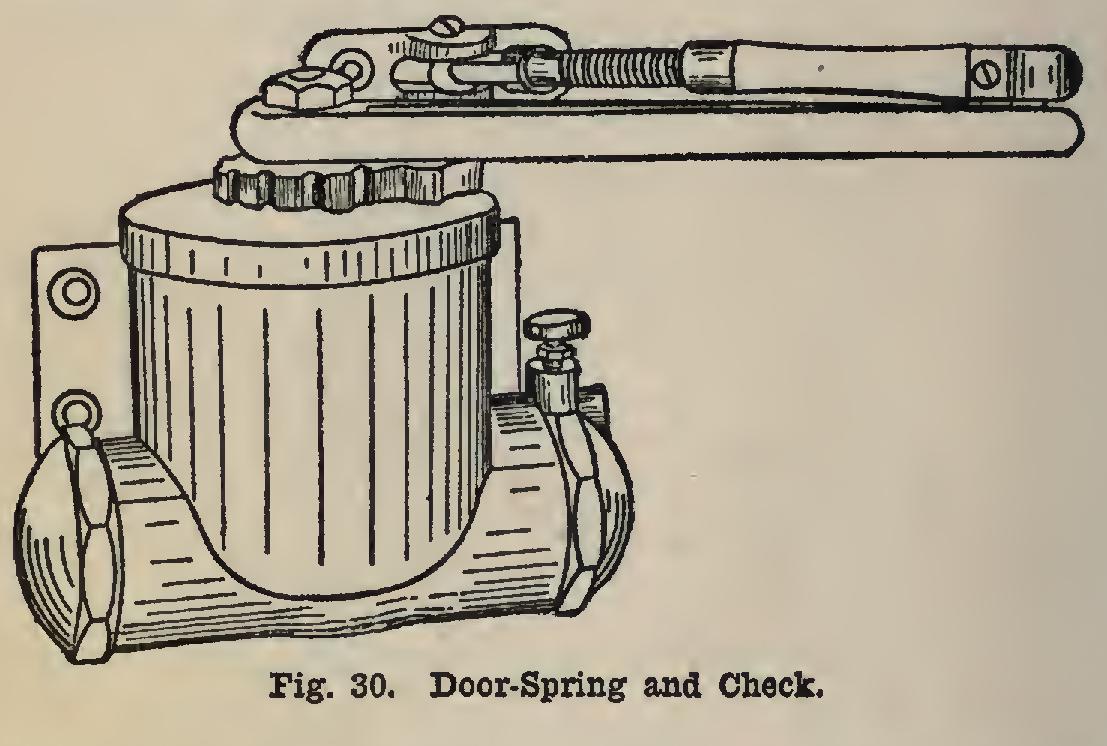

Figs. 24, 25, and 26 show three other forms of bolts in common use. The barrel bolt shown in Fig. 24 is one which is familiar to everyone.

This is made in all lengths from 2 inches up to 8 inches. The 8-inch bolts are made of wrought iron in the better grades, and weigh about 16 pounds per dozen.

The square and neck bolts shown are used for the same purposes as the barrel bolt. The square bolt has a shoulder, shown in the figure, which, when the bolt is shot into position, is forced outward by a spring back of the bolt bar, and prevents the bolt from sliding back from the strike without first depressing the rounded end of the bolt.

In the selection of any of these types of bolts, several points should be borne in mind. Bolts are mainly intended as a means of protection and can be operated solely from the inside of a door. Therefore strength is the factor to look for, combined with ease of operation.

The metal casing which holds the bolt, and the strike or keeper which receives it, should both be of good material, as strongly put to gether as possible. Flimsy or thin materials which will bend or break as soon as force is ap plied to the bolt, are useless in such a location. Another point to notice is the manner in which the bolt is moved. The metal knob shown on the barrel bolt in Fig. 24 furnishes a good grip for the fingers, while the slide shown in Fig. 23 would not be suitable on heavy bolts which are liable to stick or bind. Such bolts for doors are usually provided with knobs or levers which present a good grip.

Tapered end bolts are advised in cases where a drawing together of the fastened parts is de sired, but these generally require an application of considerable pressure.

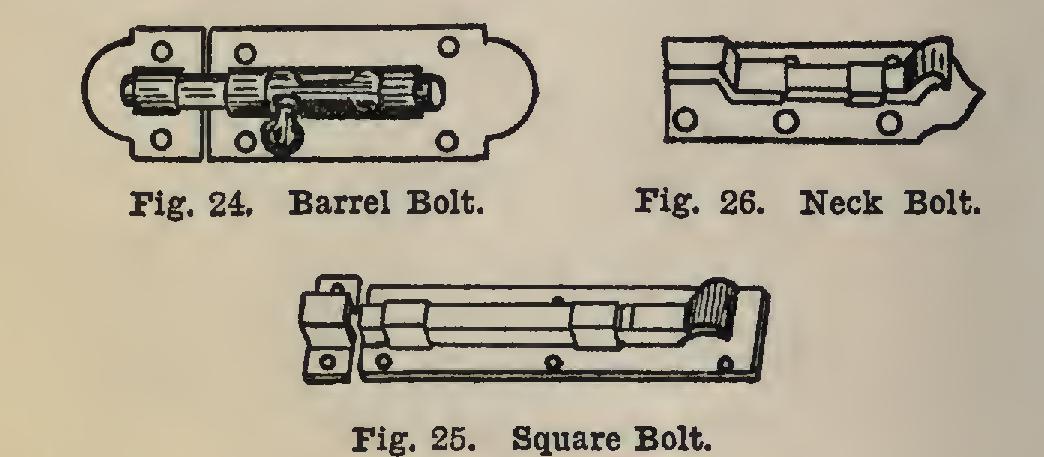

When it is desired to leave a door ajar for purposes of ventilation, and still have protection in the form of a fastener, the device shown in Fig. 27 is frequently used. This consists of a strong, light chain with a slide attached to one end which fits into a special slot in the metal part screwed to the door. The other end of the chain is connected to a plate which is screwed to the casing of the door. The length of slot and

chain are such that the slide cannot be removed from the slot without shutting the door to at least a very narrow crack, thus preventing a person from the outside from inserting the hand and removing the slide.

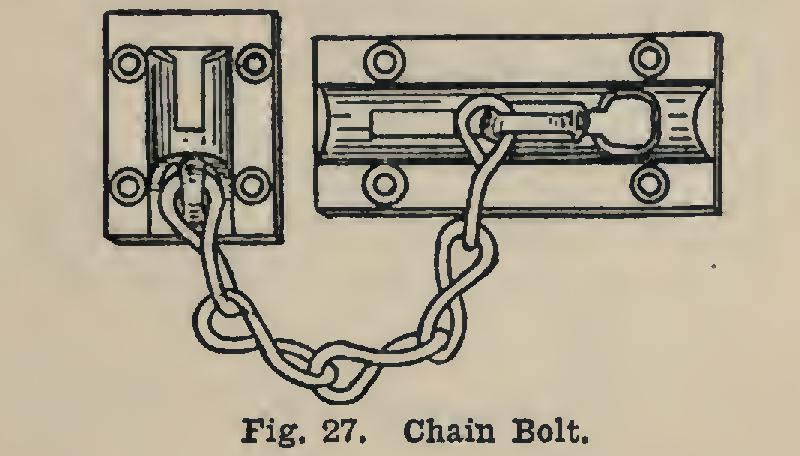

Often it is desired to have a door held open either full back or at some particular angle. When such is the case and the use of hooks is to be avoided, the device shown in Fig. 28 may be used. This consists of a barrel form of spring bolt fastened to the bottom rail of the door and provided with a soft rubber tip which may be replaced when worn out. The bolt is held up by the spring, when not in use; and when pressed down by the foot, it locks. To release the bolt, press on the plate surrounding the bolt. The length of this bolt is 7 inches.

Fig. 29 shows a form of which is often used where spring butts are not desired and where a door is desired to be self-closing. The same disadvantage remains in the use of • this spring as was referred to in the case of spring butts. It is often better to use an ordi nary form of coil door-spring which can be hooked on or disconnected at will.

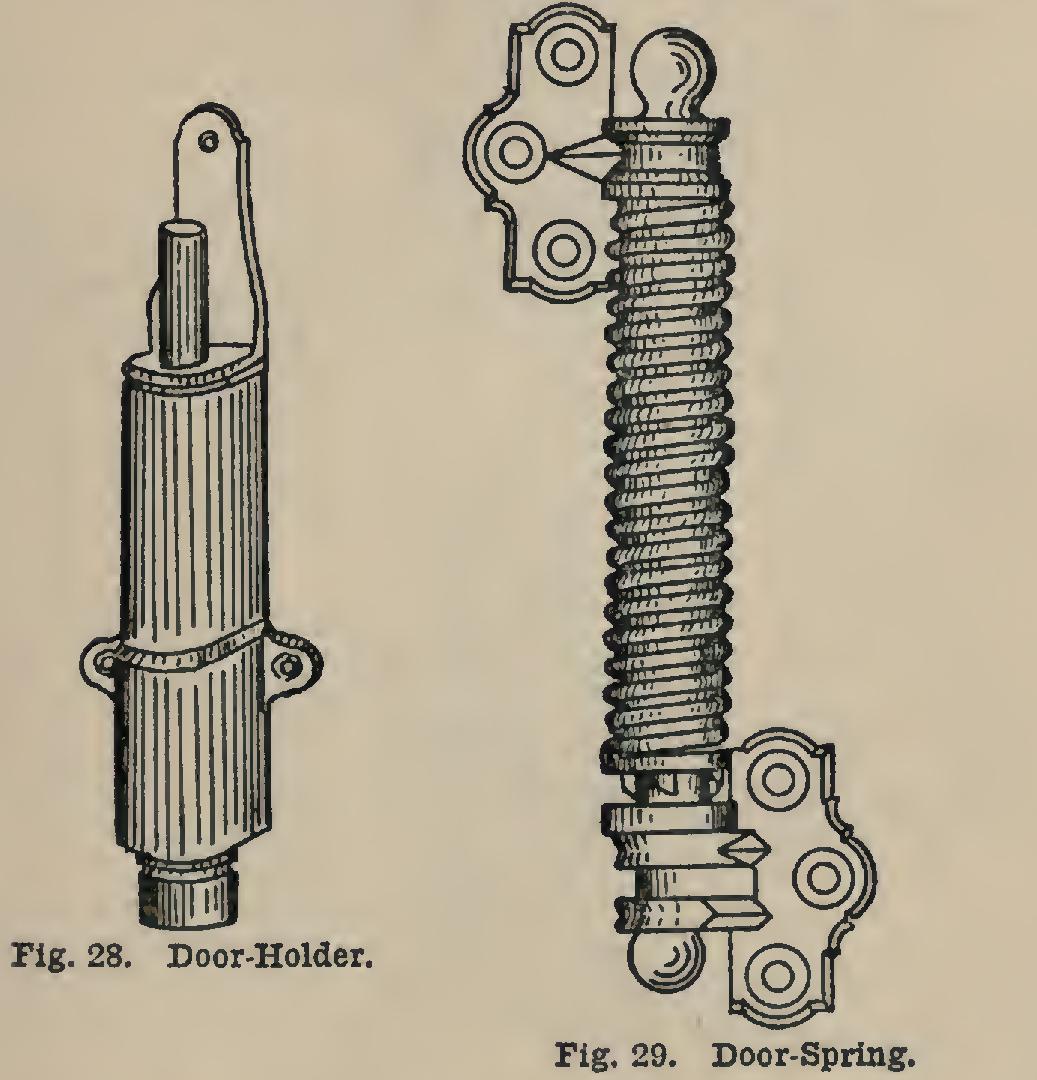

A device which will prevent the slamming of doors and still preserve the self-closing feature, is shown in Fig. 30. This represents one of many types of combined door-spring and check which are on the market. The check principle is em bodied in the action of either a liquid or. pneu matic piston which allows the spring to act grad ually in shutting the door. The cost of such checks varies from $1.25 up to $13.00 for the heaviest forms. This spring check is fastened to the top of the door and is generally reversible, but it is better to order them for right- or left hand doors as desired.

Fig. 31 shows a common form of door-stop. The use of such devices, either in the plain wood form shown here or in the more expensive metal stops, is recommended as a preventative against unsightly marring of walls by the striking of door-knobs. Another form is often screwed into the floor, thus permitting a heavy door to swing back only through a desired angle.