Miscellaneous Framing

frames, blocks, feet, air, chamber, ice and food

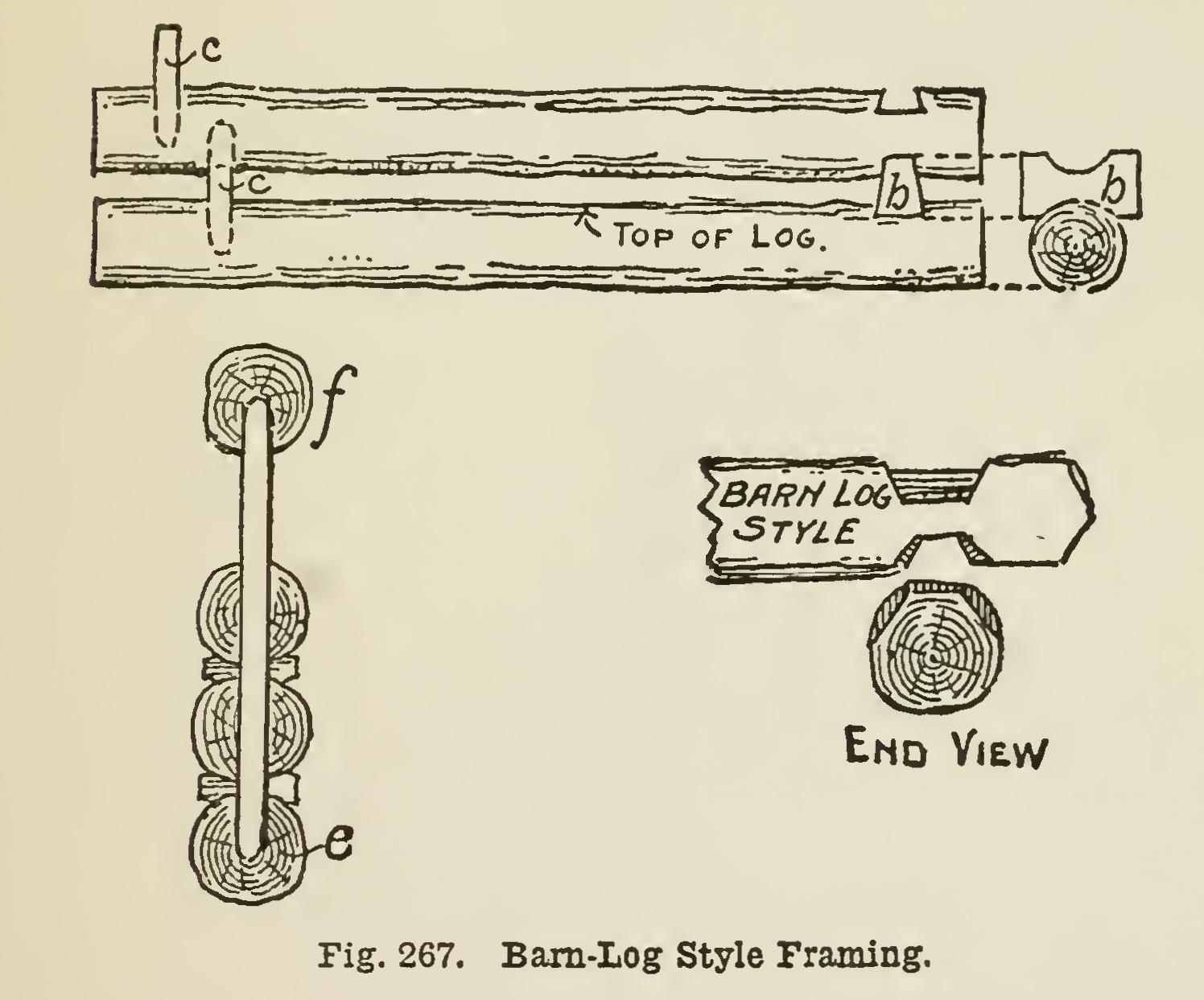

Two men usually are needed, one at each end of log, to do the fitting. Sometimes the logs are let down so as to ride on some knot, or hump. They should not do this; cut off projections.

Barn-log style (see Fig. 267) is best for out buildings; it is easier to fit, and sheds water better than the other kind. Short ends are left outside of cuts, to hold logs together. If made very long, they are very handy to run against.

A

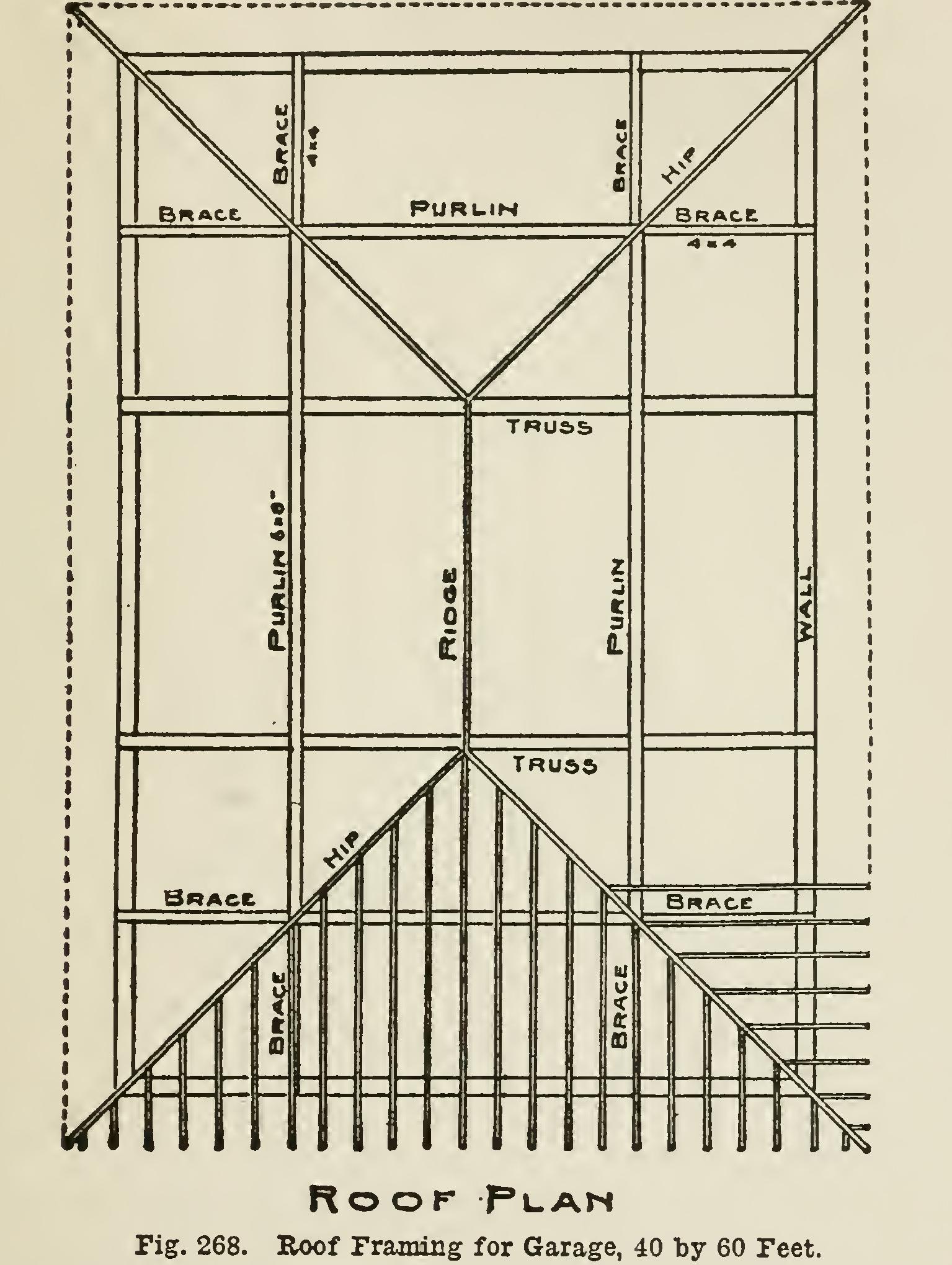

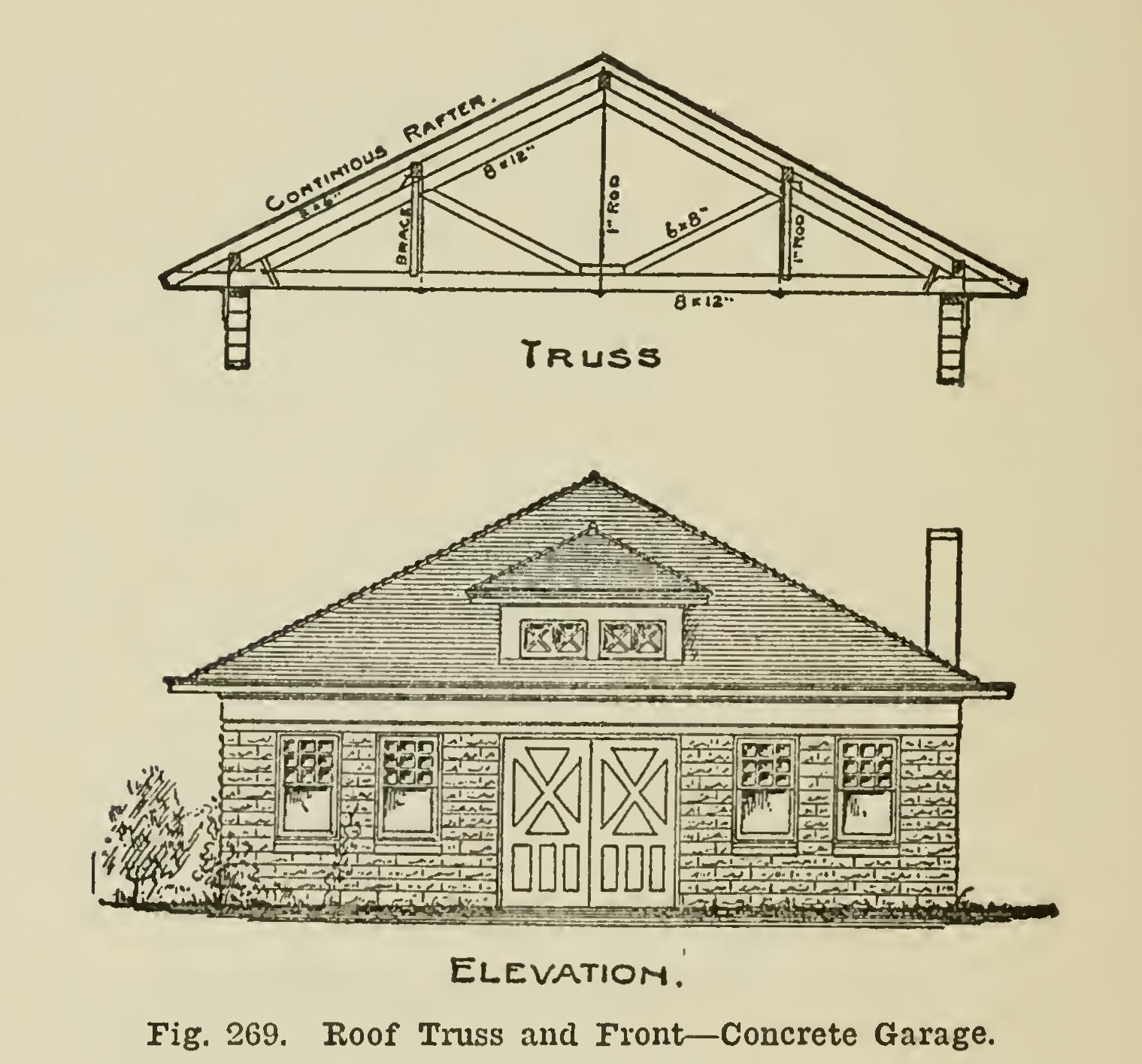

Trussed-Roof Garage. A trussed-roof garage, 40 by 60 feet, made of concrete blocks and with a hip roof, is illustrated in Figs. 268 and 269. For such a building, it is desirable to have the roof trussed so as to do away with supports through the building and yet have the structure as light and inexpensive as possible.

The size of the building suggested is a very convenient size to roof up nicely, as will be seen in the roof plan (Fig. 268). Being 60 feet in length, it will require but two trusses through the middle, which will place them at 20 feet from each end so that the hips will catch the peak of the trusses, as shown. Purlins can be run at the central point of the rafter lengths, and braced from the chord of the main trusses and from the walls, as shown in the section (Fig. 269).

As cement blocks are used for the outer walls, we submit an elevation (lower part of Fig. 269) as a suggestion for treatment. The window-frames are made to work to the size of the blocks, rather than the blocks to the frames. In this the blocks are supposed to lie 12 and 24 inches. The large door is planned for 10 feet wide, including the frames; and the windows are 3 feet wide, with frames included. This would leave 3 feet between the openings, thus avoiding all unsightly fitting of the blocks to the frames where they have to be chipped off at the ends, thereby causing uneven lengths by not having taken due consideration in laying out the work. Note, too, that caps for the openings are avoided by letting the frames extend up to the frieze. This makes an inexpensive con struction, and at the same time gives a very neat appearance. Any height of block may be used, as best suits the individual taste; but, as we said before, whatever dimension block is used, plan to work the full length and height of same to avoid patching up around the frames.

Remember, misfits can be avoided at the start, but rarely at the finish.

How to Build a Small Cold-Storage Plant. The general introduction of cold storage during recent years has had an enormous effect in stim ulating production and in opening new avenues of wealth for agriculturists and others engaged in the distribution of food products the world over.

It is the purpose of this article to deal with the principles and construction of small, simple cold-storage houses which can be cheaply and easily built, for which there is an increasing demand in many localities. The farmer, the small country butcher, and the storekeeper handling eggs, butter, small fruits, and many other perishable commodities, are all looking for some simple and inexpensive means of cold storage.

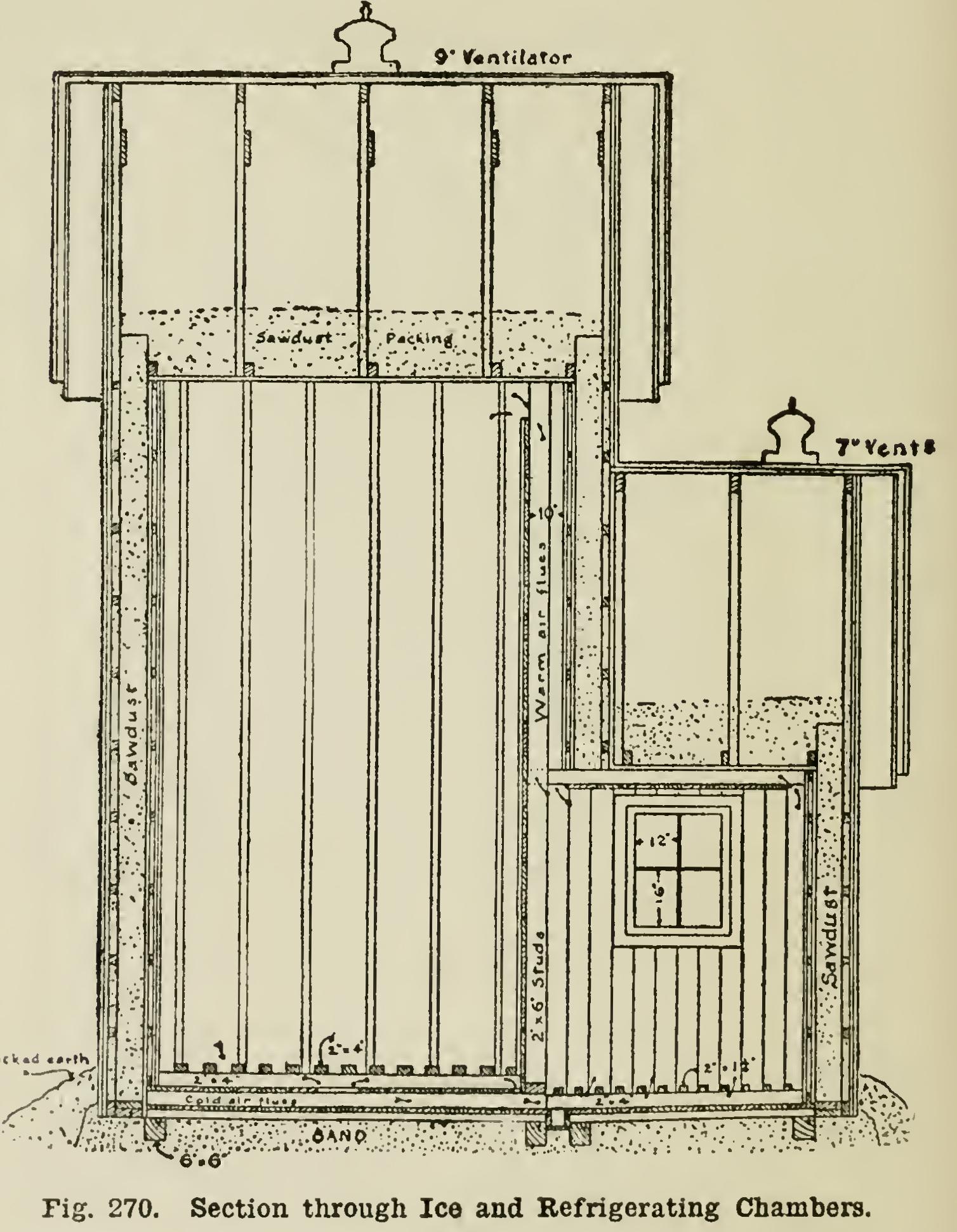

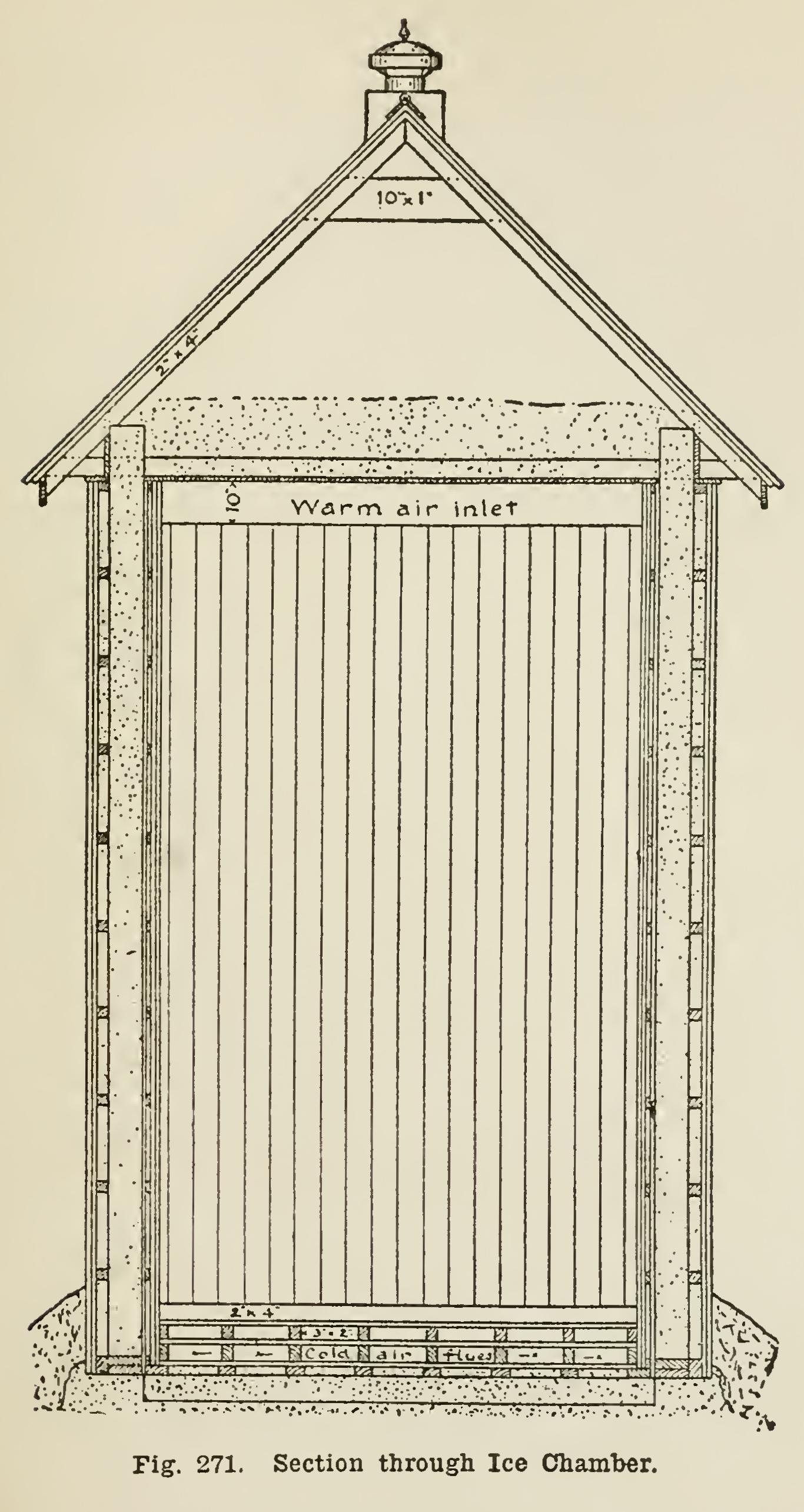

The system is based upon the well-known and widely used Hanrahan system, the best known for long-distance transportation on the railroads of this continent. It is also similar in principle to many domestic ice-chests or refrigerators, and consists in passing a current of air over a mass of ice and thence into a sepa rate chamber in which the food products are stored. From the simple natural law that warm air rises and cold air falls, a continuous circula tion of cooled air passes through the refrigerat ing chamber, and back onto the surface of the ice in the ice chamber. Any odors and gases from the food are thus brought into direct con tact with the melting surface of the ice, which absorbs them and keeps the air in the food cham ber in good condition.

The design here given is adapted from one recommended by the Ontario Government (Can ada), and has been built in many localities with complete success.

The higher portion is the ice chamber, the lower the food chamber. Each portion has a ventilator, fixed on the ridge. The roofs :Ire of shingles, laid on one-ineh hoarding in the usual manner, and capped with five-inch ridge boards and two-inch roll. See Figs. 270 and 271.