Miscellaneous Framing

chord, inch, fig, nailed, bracket and scaffold

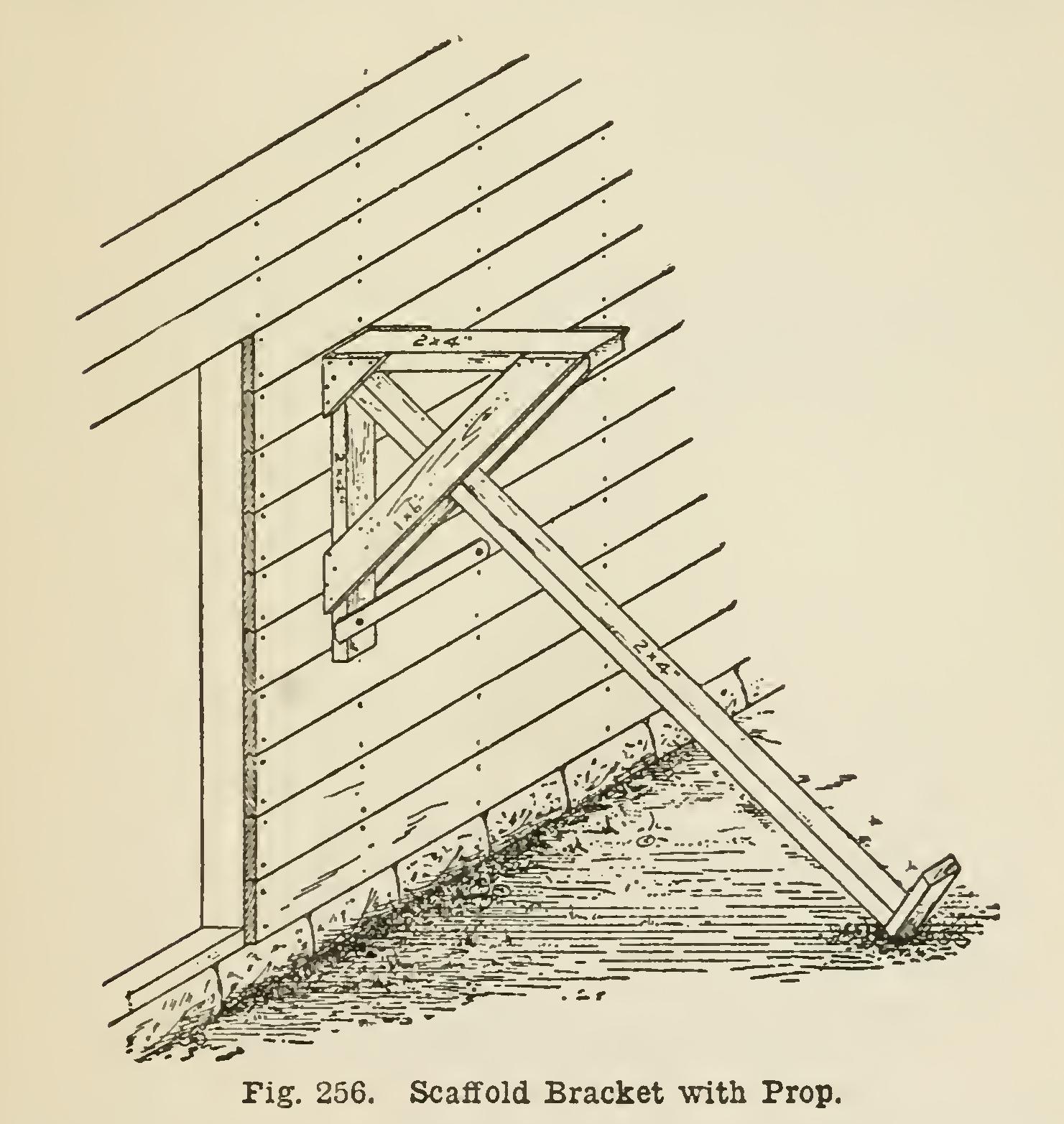

MISCELLANEOUS FRAMING Scaffold Brackets. A scaffold bracket that is handy, safe, and much used by carpenters is illustrated in Fig. 256. The construction is very simple and is plainly shown by the sketch.

To use it, first take the bracket and set it against the wall, and insert a two-by-four in bracket and raise it to the height you want the scaffold. Set end on ground, and drive stake in solid ground. A strip is nailed to the bracket and to the sheathing to prevent side slipping.

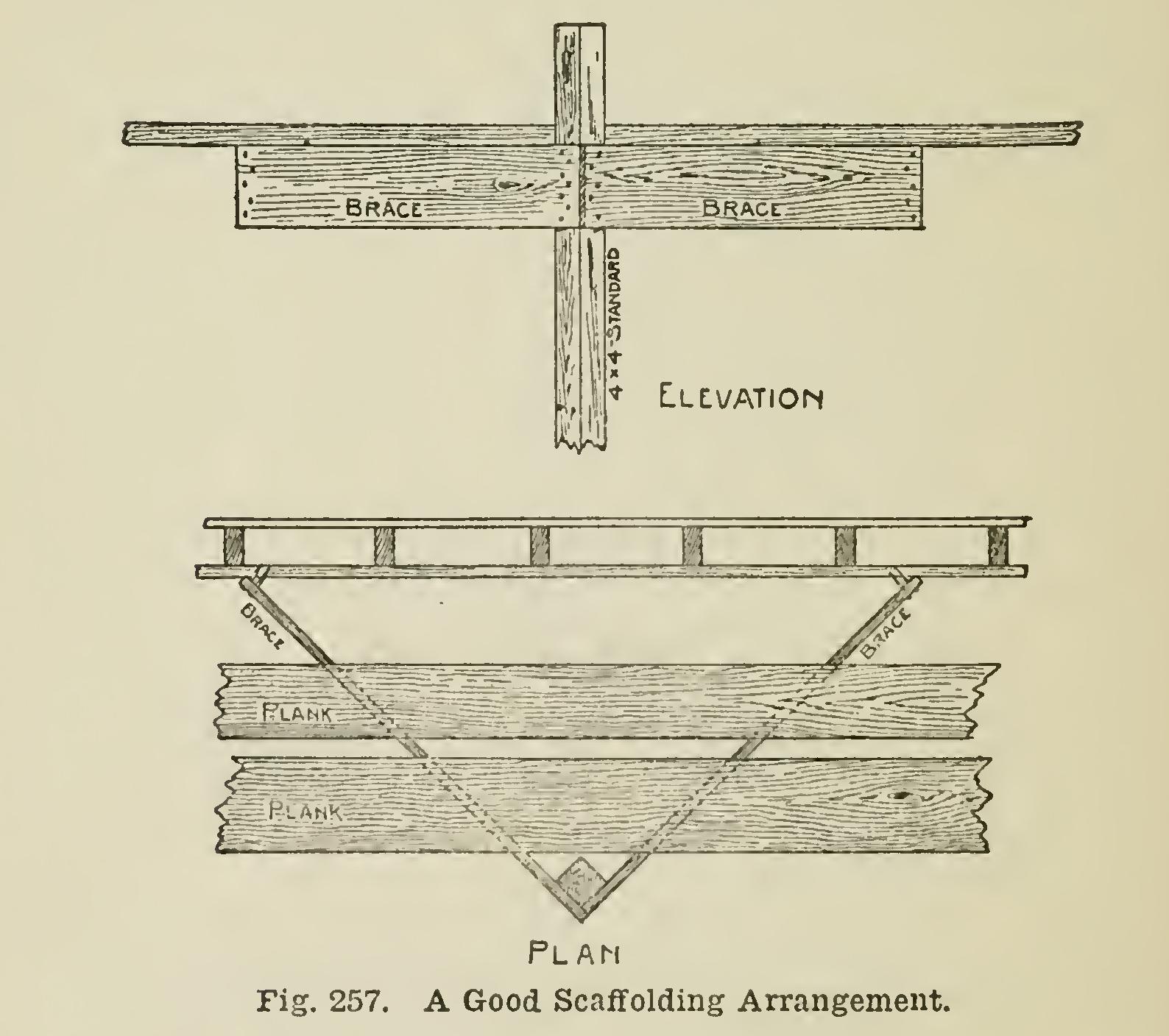

Another scaffolding arrangement is shown in Fig. 257. It has much to recommend it, and appears to be superior to the sort of temporary scaffolding usually erected about a building, where the horizontal support is nailed at one end to an upright scantling, and at the other to a block nailed against the outside of the wall.

It will be seen from the sketch, that two horizontal pieces instead of one are used, thus providing against lateral movement, without the aid of the diagonal strips that are nailed to the uprights and which are always more or less 'in the way when the workmen find it necessary to pass in and out beneath the scaffolding.

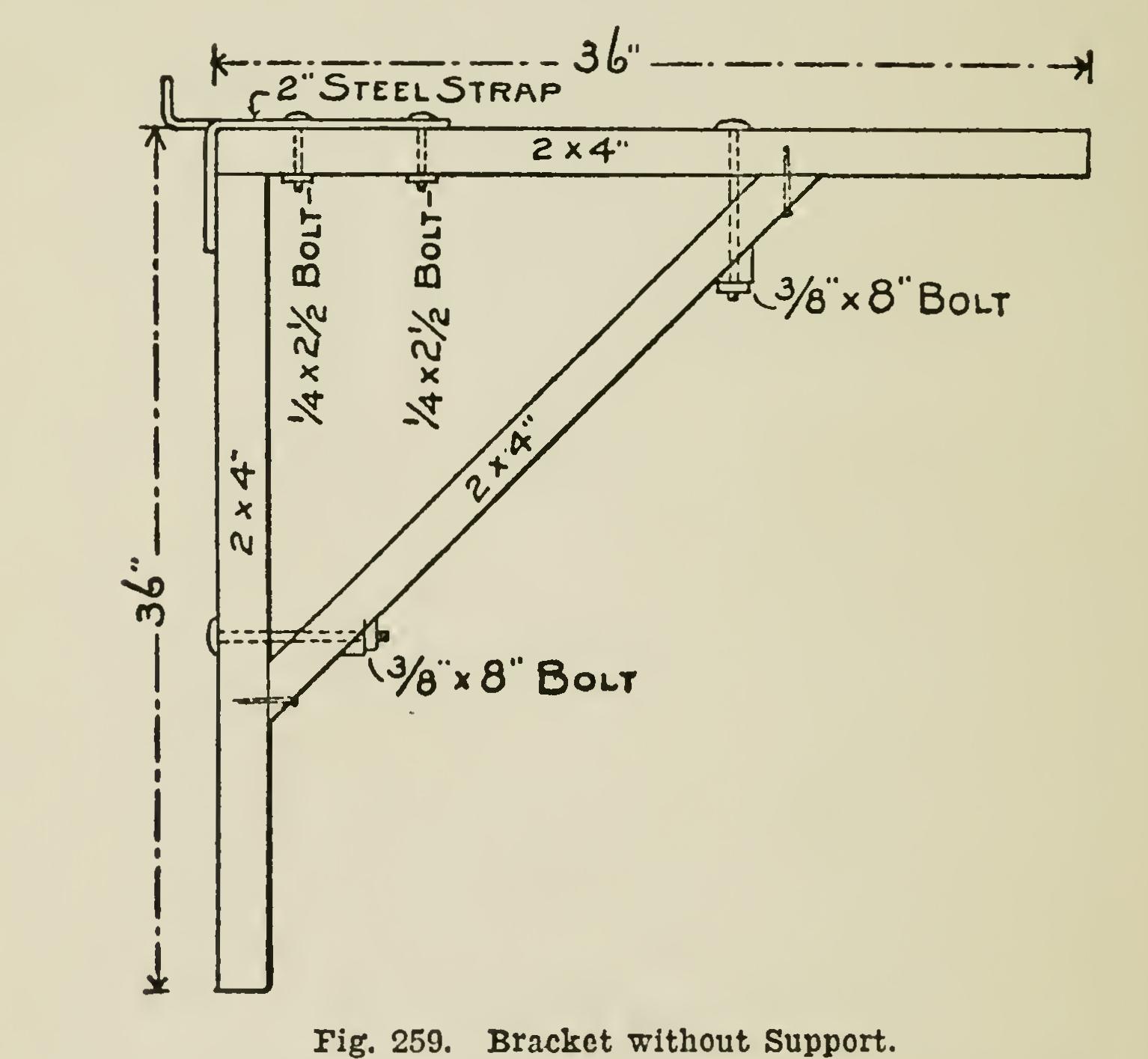

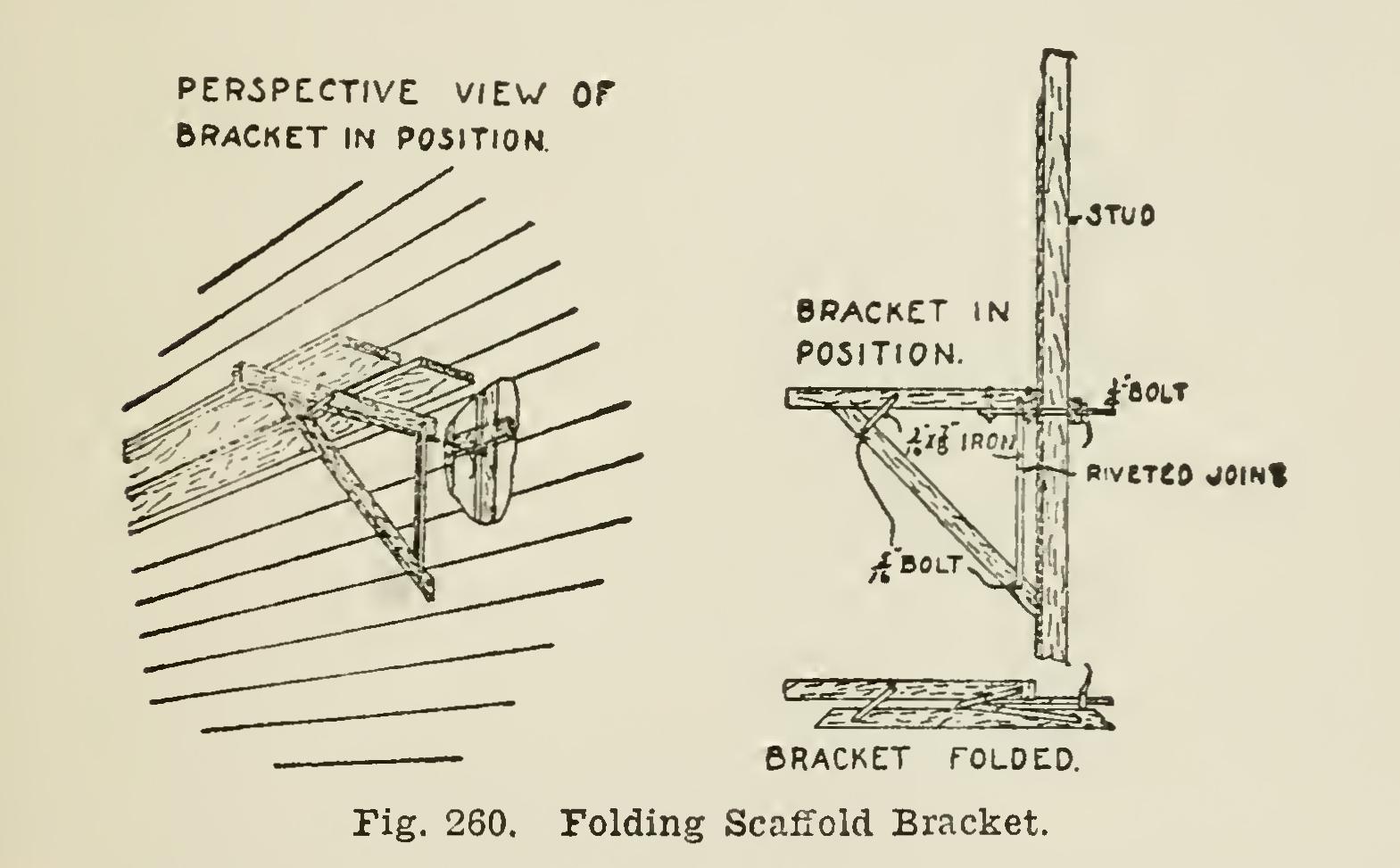

Scaffolding brackets to be used without sup porting legs are shown in Figs. 258, 259, and 260. The (Efferent forms are interesting.

In Fig. 258 the arms are made of 2-by-4 sur faced white pine; and the braces, of 1-by-4. All parts are made exactly alike so as to be inter changeable in case of accident. The braces are let in with a shoulder to give additional strength. Bore the hole exactly the right dis tance from the heel, and see that the bolt fits tight to prevent turning. Use a large washer under the head of the bolt. These brackets may be bolted to patent sheathing, the same as on the common sheathing, or may be stood on the ground with the short arm turned to the wall. They make a good scaffold for siding. Paint ing them adds to their durability and appear ance.

In Fig. 259, the arms and brace are made of 2 by 4-inch surfaced white pine. The brace is nailed to the arms, and is also fastened to same by a bolt % of an inch by 8 inches. There is a

piece of wagon tire one foot long bolted with two bolts 1/2 inch by inches to the 2 by fl inch, with a rounded hook on the end extending of an inch beyond the corner and 2 inches up. There is a piece of iron by inch, and 4 inches long, nailed on the sides of each arm where they come together. This helps to strengthen the scaffold.

Fig. 260 is a sketch of a folding bracket. The arm is made of 2 by 3-inch hardwood. The brace is four feet one inch long, and takes up very little space when folded. This form of bracket is easy to move from one job to another, which is a great convenience.

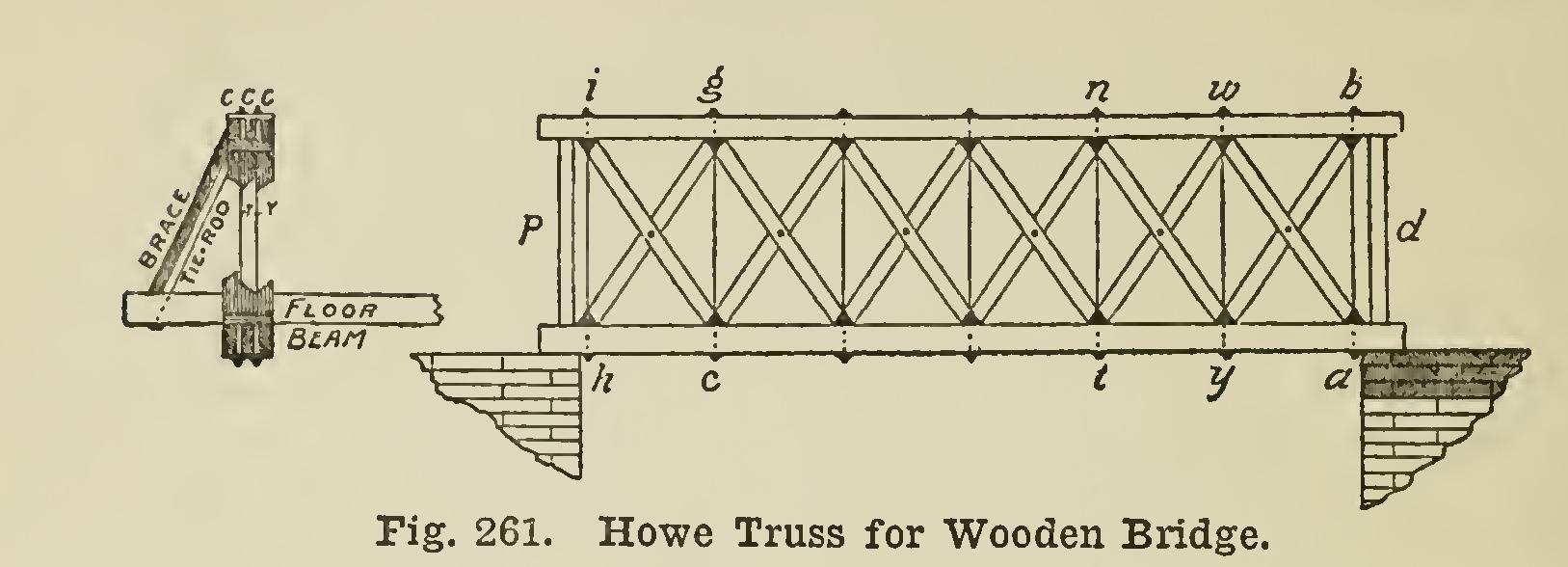

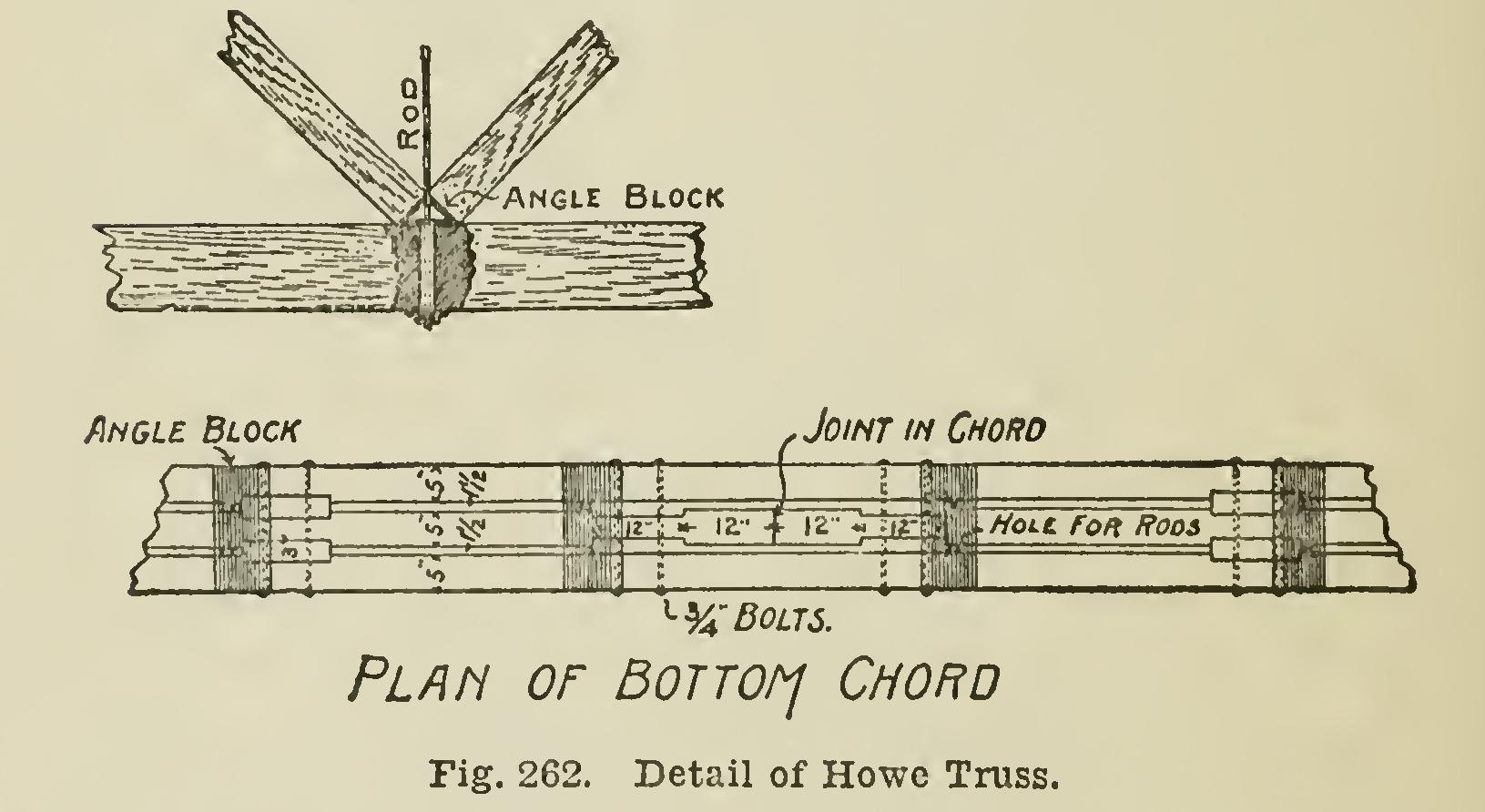

Road Bridge. Fig. 261 illustrates a small wooden Howe truss bridge. The top and bottom chords are made up of three or more parallel timbers c c c, placed a small distance apart so as to let the tubes on the angle blocks which receive the tie-rods r r pass between them. The main braces are in pairs or in threes; the pieces composing them abut at top and at bottom against triangular angle blocks (see Fig. 262), which are usually made of cast iron, being hollow and about one-half inch thick and strengthened by inner ribs.

These blocks extend across the three or more chord pieces, having two or more hollow tubes extending down between the chord members, with the tie-rods passing through the tubes. The tubes are of such length as to come flush with bottom of chord, in the case of the lower chord (and top in the upper chord), the object being to prevent the pressure on the diagonals from crushing the chord, by letting the strain of the plate washer on the tie-rod rest on the end of the angle-block tube.

Owing to the length of the chord members they are usually spliced; and, as the lower chord is a member in tension, the joints are clamped, the clamps being gained about an inch and a half, and the key blocks about one inch, into the chord, the chord bolts passing through the whole.