Elements of House Framing

stone, frame, furring, nailing, blocks, shown, base and cement

In some parts of the country a cement stone block building can be put up quite as cheaply as a frame building. First there is the saving in paint, for the outside wall requires no painting. Second, the blocks are hollow, producing a dry wall without furring on the inside, and plaster can be applied directly to the blocks on the inside, thus saving the furring and the lathing. Third, the blocks being uniform in size, only a very thin coat of plaster is necessary. Fourth, all the frame work, sheathing and siding is saved. Taking all these items into consideration, the cement block house can be erected nearly or quite as cheaply as the frame house.

The use of cement building blocks, where no furring is used, makes it necessary to provide some means of securing the woodwork or finish of a building, such as the window casings, base boards, etc. It is not practical to nail the wood work directly into the blocks, and it is doubtful if such a thing could be done. Woodwork can be nailed more or less to a brick wall, but not very successfully, and nailing finish to a cement stone block wall is something that few would care to try.

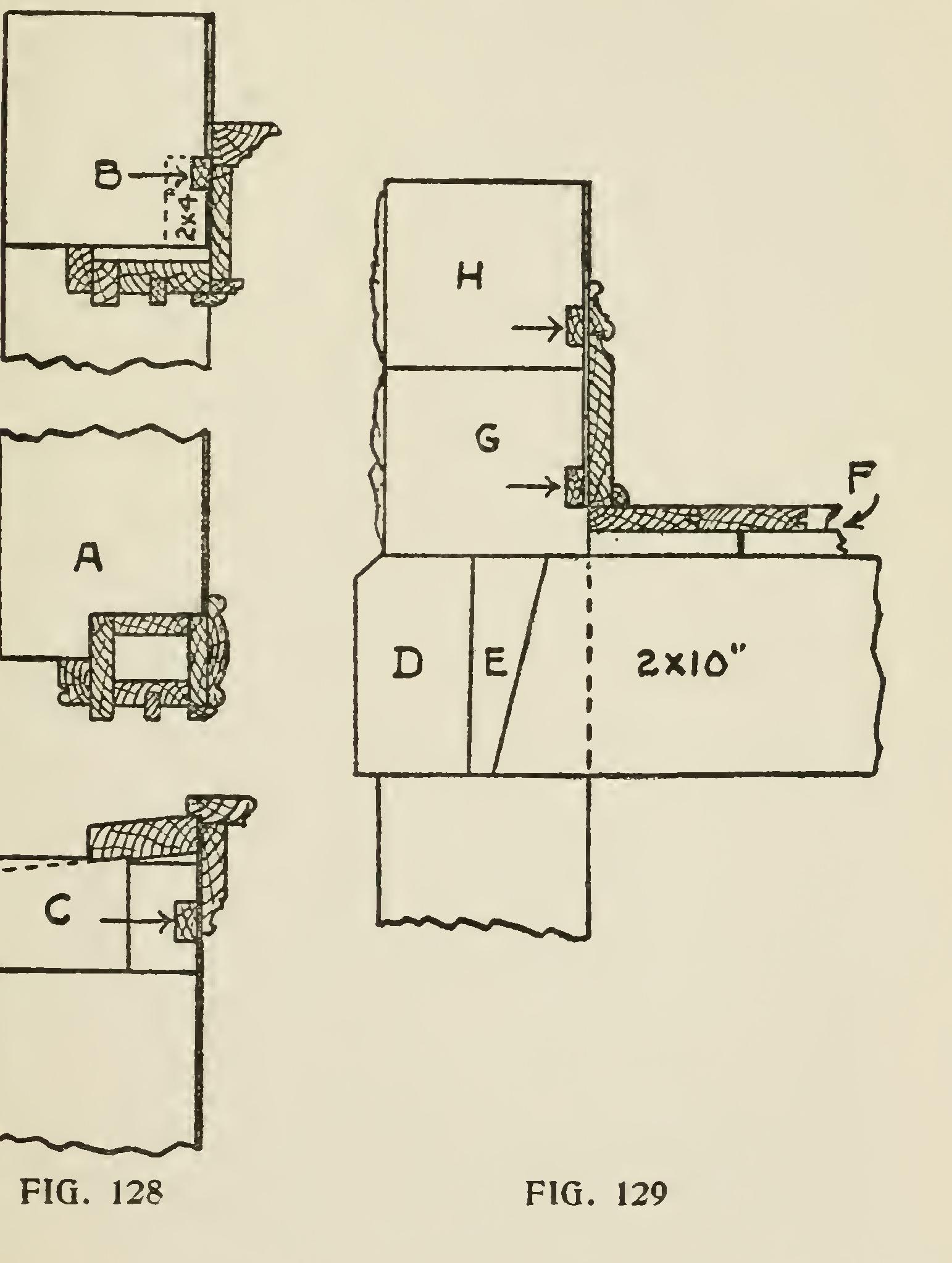

In Fig. 128 we show a wail nine inches thick, which is about the least thickness that will admit a window frame in good shape. The jamb stone at A just comes P bout flush on the inside of the box frame, leaving just a little for the plaster. This makes it all right for nailing the side casings on the frame, leaving just a little of the casing to reach over on the main wall and completely cover ing the frame box. This makes the nailing for the side casings all right. With the head casing it is different. In this case there is nothing to nail the cap trim of the frame to except at the very lower edge. And in order to get a good job of finishing some means must be provided to nail the top edge.

As the stones are made in a mold it would be very easy to put a 1 by 2-inch strip in the right position in the mold to form a recess in the lintel stone, as shown at B, in which could be driven a 1 by 2 furring strip which, if put in tight, would make a sufficient nailing for top of cap. Again, the furring strip could be molded right into the lintel when it was being made, and thus save the time of driving it in after the stone was laid. Again, the lintel stone could be molded with a recess on the lower inside edge just sufficient to take in a piece of 2 by 4, which might, perhaps, be still better, as shown by dotted lines. The

window sill shown at C might be backed with a smaller stone molded with a recess to receive a 1 by 2 furring strip to make a nailing place for the bottom of the apron to the window. The stool and top part of the apron could be readily nailed to the wooden sill of the window frame.

In Fig. 129, D represents a plain bevel edge wide base course, the depth of which is the same as the joist used for the floor. E shows the back ing stone, which should be made just the right size to fit in between the joists. The floor, which is double, is shown at F. Above are shown two courses of stone, G and H. These two courses are recessed at the proper height to receive furring strips to make nailing places for the base, top and bottom, as shown.

With furring strips driven into these recesses in the stone blocks, a continuous nailing strip is provided for the base, and one that ought to hold the woodwork securely in place. Woodwork can not be attached to stone walls unless there is some means provided for securing it, and it would seem that this is a practical and inexpensive way to provide for it. We believe it to be much better than driving in wooden plugs in the mortar joints, which hold but poorly at the best. If hollow cement blocks are to be used without furring the inside of the walls, as is customary in brick and stone buildings, then it becomes abso lutely necessary to devise ways and means of securing the casings, base and other finish.

Cutting in Studding.

There is a little matter of detail in building construction that has an noyed and vexed the carpenter ever since houses have been built with gables, which were plastered up the rafters from two to four feet in order to get a sufficient height to the ceiling in the center.

Every carpenter is familiar with the disagree able job of cutting in small pieces of studding between the gable studding along up the rafter, and the difficulty experienced in nailing the small pieces. This work, on some houses, will require a large amount of time, and contractors cannot afford to put in time where it is not needed. There is a much easier way of doing this without the use of more material and with less expense to the contractor, and resulting in a much better job. With all these advantages it looks as if the carpenter or contractor ought to know better and take advantage of an easy way of doing a good job.