Elements of House Framing

cement, building, stone, wood, blocks, grounds and block

Grounds

are used in better work, being wrought and splayed to form a key for the plaster.

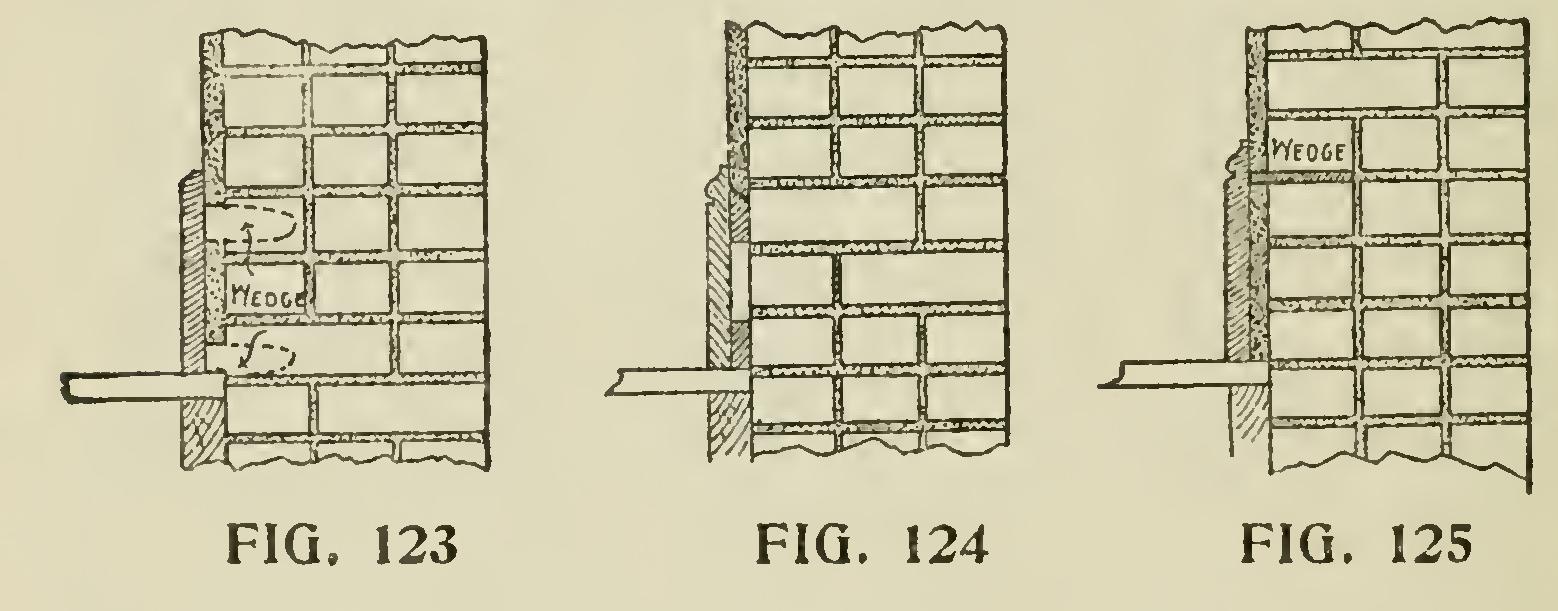

They are nailed to plugs in the bross joints, as Fig. 124, or to wood pads, as shown in Fig. 125, wh ch the brick-layer builds in the wall for the carpenter to secure his work. Metal plugs are now quite generally used in lieu of wood ; they are creased and made clamp-shape, and when built into the wall they form a perfect key. The nail is driven directly into the clamp and is held more securely than if driven into wood. The cost is reduced to the minimum and, all things con sidered, they are really cheaper than wood. In the best class of work the grounds should be mitered at the angles, and those at door and window openings should be beveled or splayed to receive and key the plastering, and being fixed perfectly plumb or perpendicular to the plugs or other nailing, they form an excellent plane to work to.

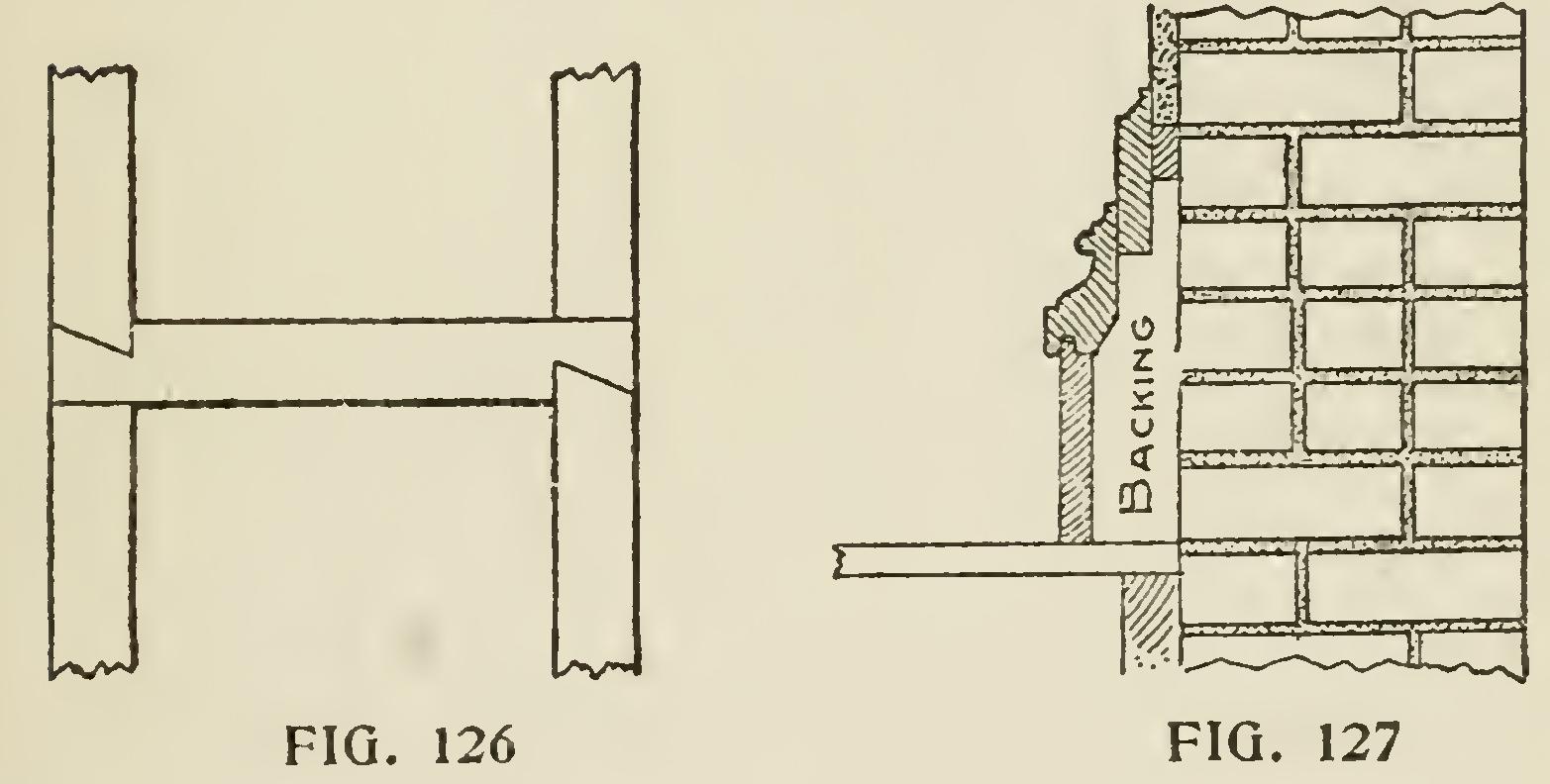

Backings are pieces of wood framed in between the studding or other work to form a solid back ing for shelving, plumbing or other fixtures. Sometimes these pieces are framed in lieu of nail ing, as shown in Fig. 126; but for all practical purposes this is unnecessary work, because if properly framed and nailed will be sufficient for most any kind of work.

Shaped backings are those which are cut and notched to receive irregular framing or different members, as skirtings, etc., used in the best class of work (see Fig. 127).

All first class work should be fixed to grounds in lieu of plugs alone, which are only fit for inte rior work; and when the grounds are fixed per fectly true, vertically and horizontally, there is no difficulty in affixing the joinery without fitting, cutting and scribing; and, moreover, the plasterer finishes his work with greater accuracy, as he has perfectly true and substantial grounds to work to.

Attaching Woodwork to Stone Walls.—The cement building block industry is fast becoming a great and growing business. Almost every issue of a trade journal brings to light some new machine for the manufacture of cement building blocks or some new use for the product.

Portland cement is one of the very best build ing materials that has ever been produced. It

is fire-proof, water-proof, strong and durable beyond all doubt when it is properly mixed and applied, and with the cheapness of it and the high price f lumber it is sure to be used in place of wood in many cases where it is practical to apply it.

For the outside walls of buildings it is a first class article when manufactured into hollow con crete building blocks. These blocks are now being made to resemble natural stone. Rock face, smooth face, tooled face or any kind of face de sired can be had at a very small expense. The usefulness to which this material can be put is almost unlimited. Artistic designs of residences, stores, school houses, churches and all kinds of buildings can be executed in fine shape, giving the buildings the appearance of magnificent stone structures.

Is it durable? This is a question that will be aksed over and over again by the dJubting ones. There is no question as to its durability when the article is properly mixed and applied. No better proof need be asked for than a comparison of a good cement sidewalk with one of stone, and finding the cement walk wearing and lasting better than natural stone. Sidewalks get more wear and rougher usage than stone put into a building, and a cement block that would stand in a walk would stand in ordinary building construc tion. Of course there might be such a thing as putting too great a weight on a building block, but this would not be likely to happen in ordi nary building, and in cases where there is great weight to support it can be distributed so that the weight will not all be concentrated in a few places about the building. The crushing strength of the cement block is fully the equal of ordinary brick work and no fear of crushing need be enter tained. Blocks that crumble easily indicate that the proper quantity of cement has not been used in their manufacture. For good blocks not less than one part of cement to five parts of sand and broken stone should be used. The mixture to be what is known as a 5 to 1 mixture and should be thoroughly mixed.