Pitches and Roof Framing

cut, square, tongue, pitch, rafter, blade, common, cuts and lines

The backing of the hip is too often neglected. In fact, in most cases is not done at all, or if it is clone, it is in a haphazard sort of a way. We have seen laborers (we will not say carpenters) take a hand-ax and hew off the corners of the hip, after it was set in place, at the time of putting on the sheathing boards. The valleys too should be backed and in most cases should be doubled on account of the downward thrust of the roof causing etxra weight on the valleys. However, it is not our intention to discuss construction in this work, but where the valleys are so doubled they should be backed one way only and that before spiking together. This makes a substan tial valley and solid bearing for roof boards.

Tail End Cut of Hip or Valley.

This, too, is one of the neglected cuts, and carpenters generally pay no attention to it further than to leave the tail end long enough to catch the facia and then scribe the end cut to correspond with that of the common rafter.

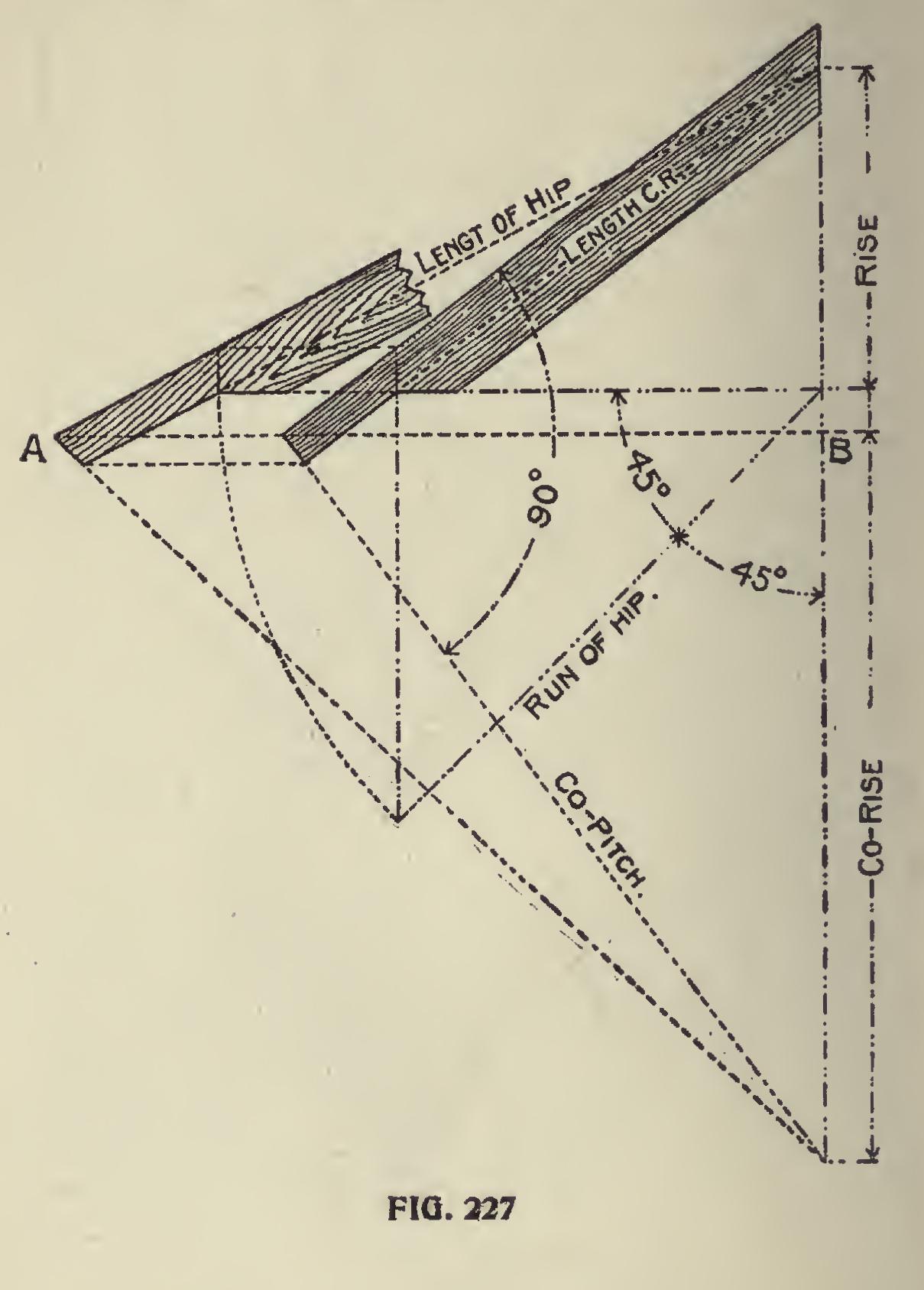

In Fig. 227 we show this cut as at "A" and how it may be obtained with the steel square. From this, it will be seen that it is rather a diffi cult thing to get at, since the measurements are, so to speak, in another latitude. In all roofs there is an unseen, or co-pitch, and the end cut of the common rafter represents that pitch, and which, if cut square, will rest at 90 degrees from the given pitch of the common rafter, and the cut in question must necessarily coincide with the unseen or co-pitch.

In

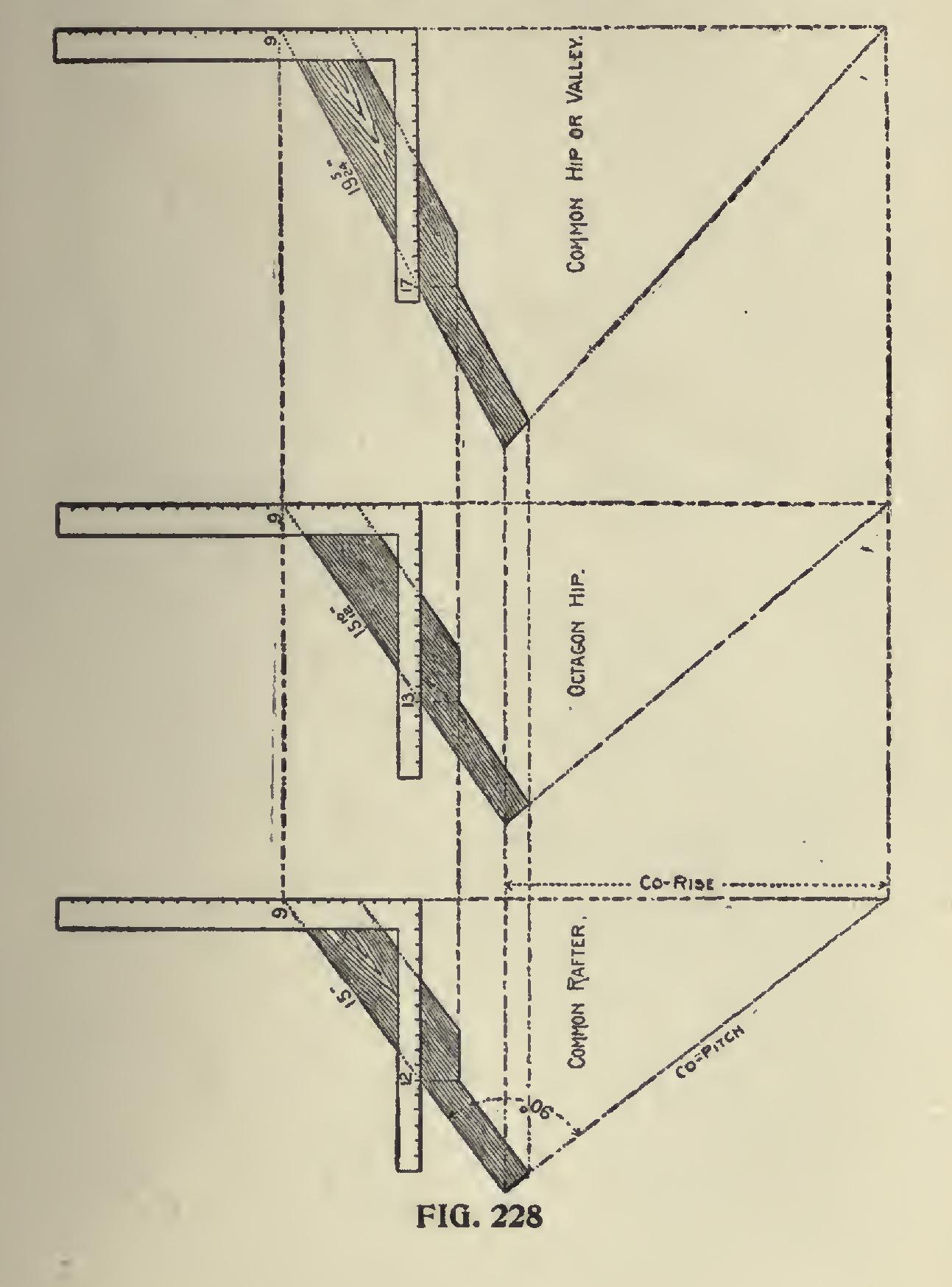

Fig. 228 is shown the application of the steel square for the seat and plumb cuts for the pitch for the common rafter and the correspond ing hip for the octagon and square cornered building. The dotted lines clearly show the angle that the tail end cut must bear to that of the common rafter.

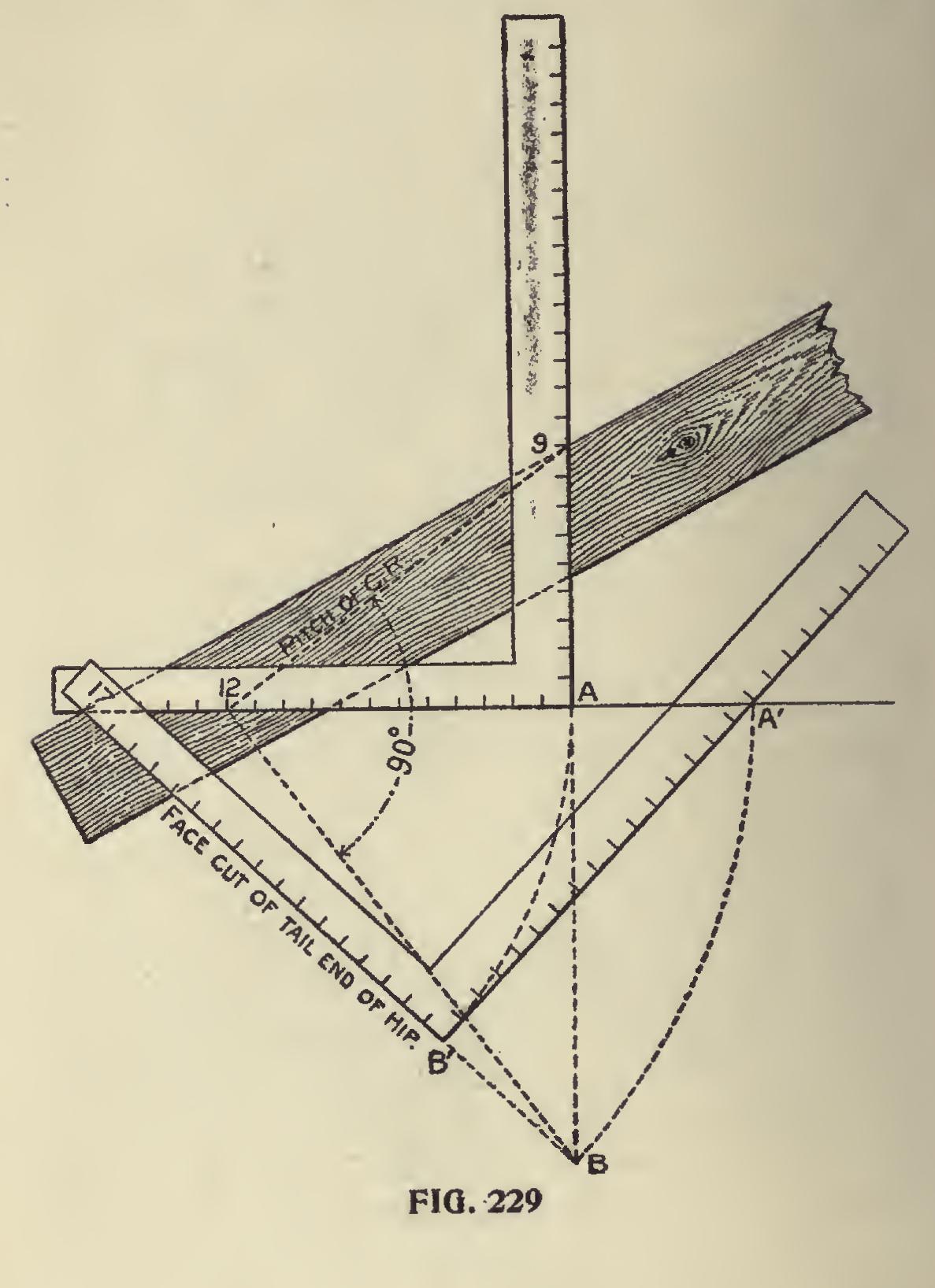

There is no general rule, so far as we have been able to find, whereby this cut can be had direct from the edge of the rafter, as in other cuts, but it may be had by taking the run (17) on the tongue and the co-rise on the blade and applying this to a line parallel with the seat cut and the tongue will give the desired cut as shown in Fig. 229.

However, this is only the angle or where the cut would be at the center of rafter. To get the proper angle on the side of the rafter, the cut would pass through the point on the seat cut as before described for the backing lines.

The foregoing practically covers all of the cuts and bevels about the even pitch roof that may be readily obtained with the aid of the steel square. There are, of course, other ways of arriving at the same result by geometrical dia grams, etc., but there can be nothing better than a thorough knowledge of the tangents of the steel square and the relation that they bear to one another.

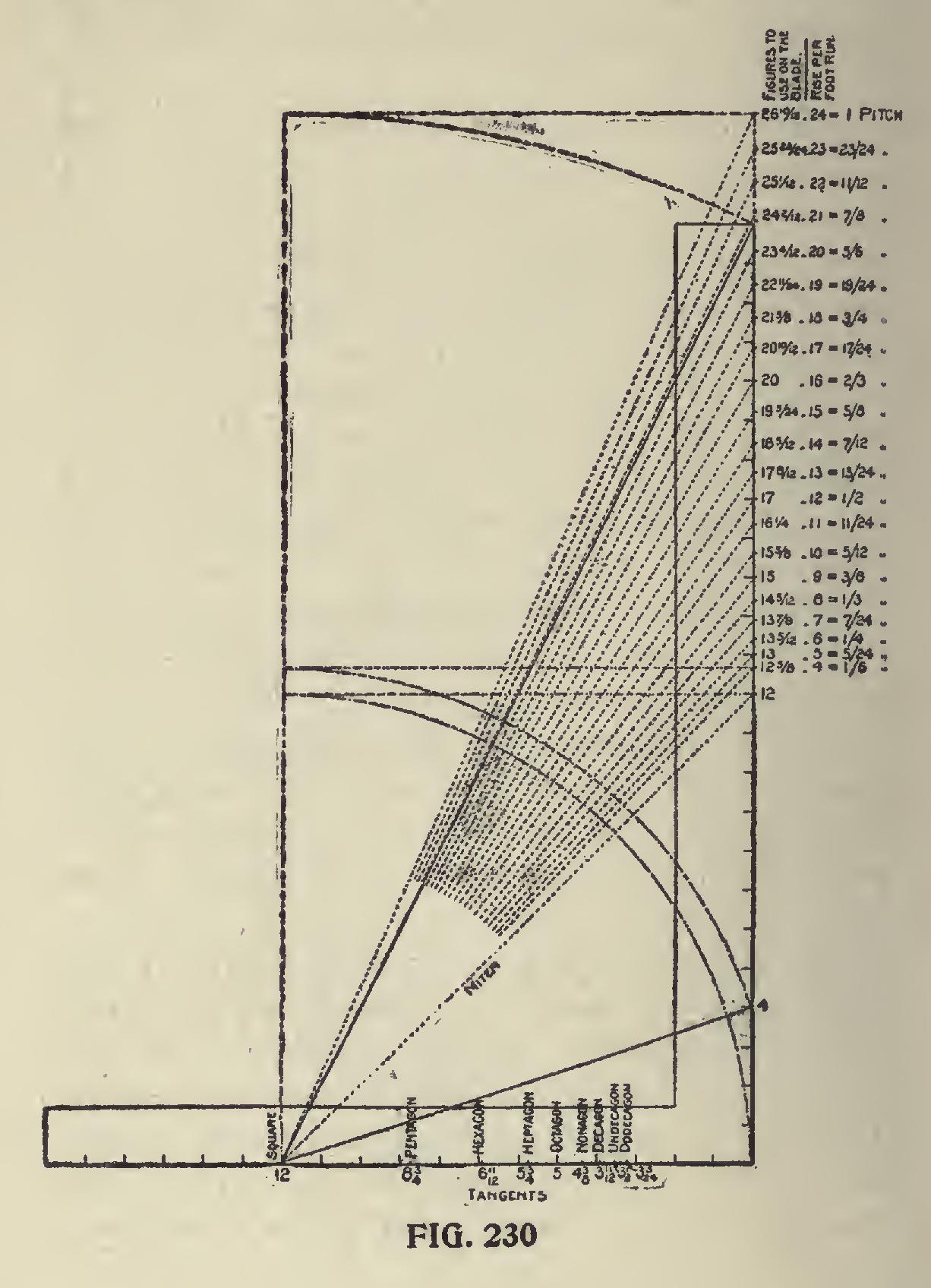

Side Cut of Jacks.—In Fig. 230 we show the side cut of the jacks from a 4 to 24-inch rise to the foot run and for polygonal corners from 4 to 12. In this illustration we show the figures to use on the steel square for twenty of the pitch lines and for the square corner and eight of the polygonal jacks, also for the level miter making in all 220 side cuts, or miters, that can be had from this illustration alone. Since the tangents of the polygons govern the figures to use on the tongue, they are as shown in connection with this illustration. Thus, to obtain the side cut of the pentagon jack for the Finch pitch, we use 81 on the tongue and 15 on the blade. The blade giving the cut.

Hexagon Jack.—Proceed in like manner for the hexagon jack, using 6 11-12 on the tongue, and so on to the end. The reader will notice that several of the pitch lines are beyond the length of the blade and in that case it is necessary to re duce the scale, which may be done by taking one-half of the lengths here given on the blade and tongue. The tangent for the triangle is practically 201 inches, which is beyond the length of the tongue, so that it is necessary to make a reduction in the scale, so as to bring it in on the tongue. Then if we take one-half of 20i, which would be 101, on the tongue, and one-half of the length of the pitch lines as given, will give the desired cut. Thus for the 1 pitch it would be 101 on the tongue and 7i on the blade. The blade giving the cut.

We fancy we hear the critics say, "Why go into all these side cuts of jacks for roofs that are not in style and never will be?" To such our answer is: If you understand the principle of the side cut of the jack for a common square-cornered building, you will understand for the polygonal jacks whether you are ever called upon to frame them or not.

As we write these lines we are reminded of a contractor who had a hexagonal roof to frame. He had a good working force on the job and the time that was lost in help and waste of material would have made a nice profit. Another time a lot of masons were laid off one-half day to give the "Boss Carpenter" time to go to a neighbor ing barn where he could have a level floor to lay off a diagram for a full size octagon template for the masons to work by, and yet these men thought they understood the square. They could frame the common hip and valley roof, but when they came to something a little out of the ordinary they did not understand the true prin ciples involved. If these men had possessed a knowledge of the tangents and how to apply them on the steel square, they would have known in a minute's time what figures to use for all of the cuts, lengths and bevels required in the work.