Pitches and Roof Framing

inches, feet, run, length, figures, rafter, common, board, cuts and square

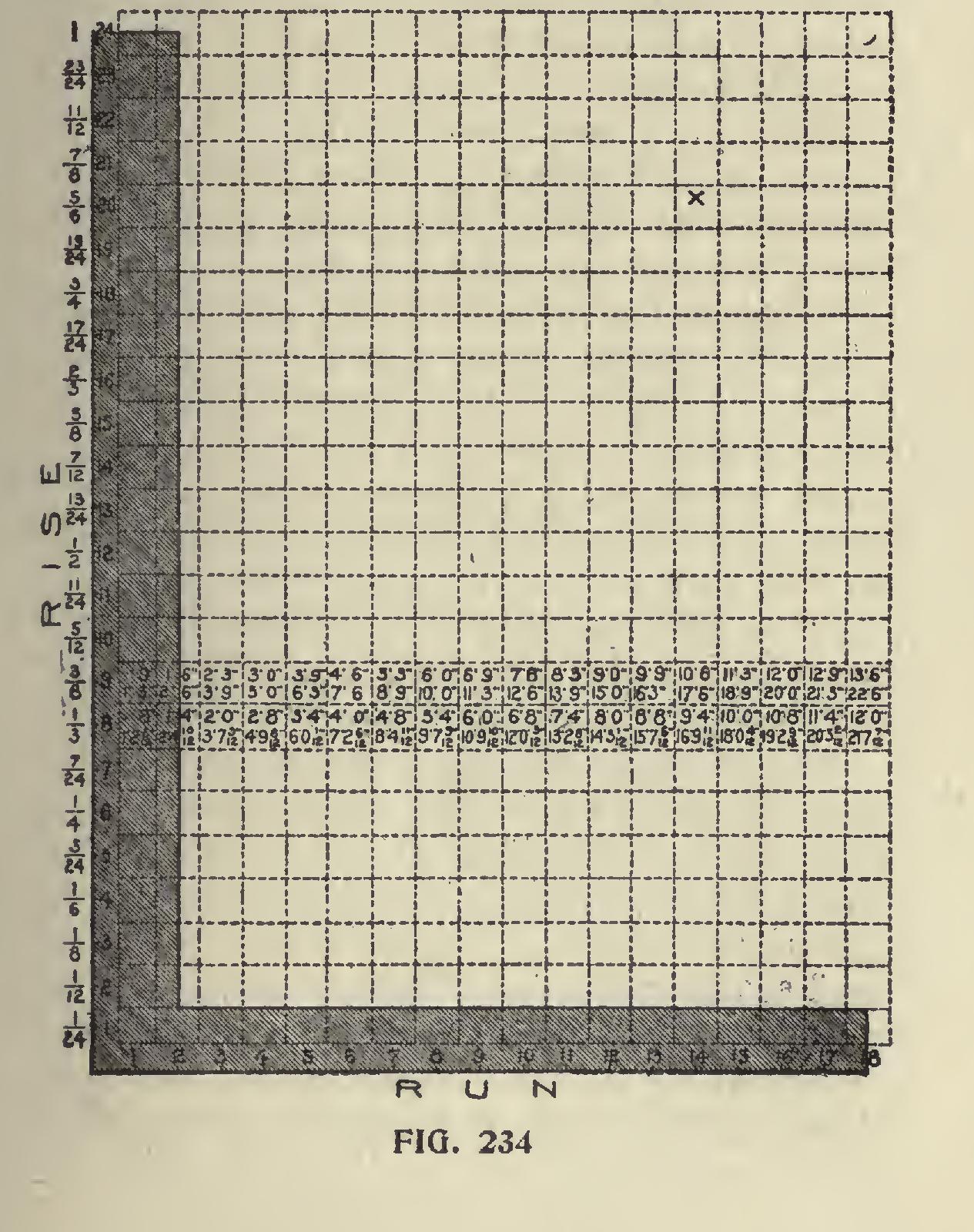

Lengths, Cuts and Bevels of Common Rafters. —In Fig. 234 is shown a part of a very con venient table for the length, cuts and bevels for the common rafter up to an 18-foot run and with a rise from 1 to 24 inches to the foot. We have only given the figures for two of the pitches (1-3 and 3-8).

The figures on the blade represent the rise to the foot run. The fractional figures to the left of the blade represent the pitch of the common rafter. The figures on the tongue represent the run in either feet or inches. Therefore, if we wish the length of the common rafter, for a 16-foot span for the pitch, we take one-half of the 16 for the run on the tongue (8) and look in the square opposite and we find 6 feet which repre sents the rise and 10 feet represents the length of the rafter. If it be an 8-inch run, then the figures found there would represent as many inches.

This table is very convenient in finding the com mon difference in the length of jacks; as they are but a part of the common rafter, their lengths may be readily found as follows: If they are spaced one foot from centers, then the length of the first square will be the common difference. The length of the second jack will be that found in the second square, and that for the third will be found in the third square, etc. If the jacks are spaced on 24-inch centers then find the lengths in every other square. If they be placed on 16-inch centers, look under the 16th run and consider the length found there as inches. If they be placed on 18-inch centers, look under the 18th run, etc.

There are twelve scales in this table. Each figure in the run representing a scale and all giving the same cuts. Thus, the seat and plumb cuts for the common rafter are as follows: Take the number of any run on the tongue and its rise found in the square above and oppo site the desired pitch, on the blade will give the seat and plumb cuts. Take the number of any run on the tongue and the corresponding length of the rafter on the blade will give the side cut of the jack and also the face cut across the roof boards to fit in the valley or over the hip. The blade giving the cut on the former and the tongue in the latter.

Take the length of the rafter for any run on the blade and its rise on the tongue and the latter will give the miter cut across the edge of the roof boards, which is the same as the miter for the square hopper. The figures for the full scale are found in the twelfth run for the above cuts as before illustrated.

To Find the Side Cuts for the Polygonal Jacks. —Take the tangent on the tongue (see Fig. 230) and the length of the common rafter found in the twelfth run on the blade and the latter will give the cut.

Lineal Board Measure.

This table also con tains a complete lineal board measure for any width of board up to 18 inches, as follows: Let the figures on the tongue represent the width of the board and those on the blade the length. The top figures in the intersecting squares opposite these numbers will be the con tents of the board in feet and inches, as follows : A board 6 inches wide and 9 feet long con tains 4 feet 6 inches. A board 17 inches wide and 9 feet long contains 12 feet 9 inches. A board 15 inches wide and 8 feet long contains 10 feet, etc. A board 14 inches wide and 20 feet long, the answer would be found in the intersect ing square opposite the starting points, as at X.Thus it will be seen that a completed table of this kind would come very handy as a ready reckoner. The reader will notice in the pitch that the lengths are without fractions. This oc curs at three places on the blade-5, 9 and 16, respectively. Thus in the 1-3 pitch, the lengths end in fractions and are expressed in twelfths. For an 8-foot run the length would be 8 feet 7 5-12 inches. For an 8-inch run the 5-12 may be dis carded as it represents less than half of a twelfth of an inch. The answer would then be 9 7-12 inches.